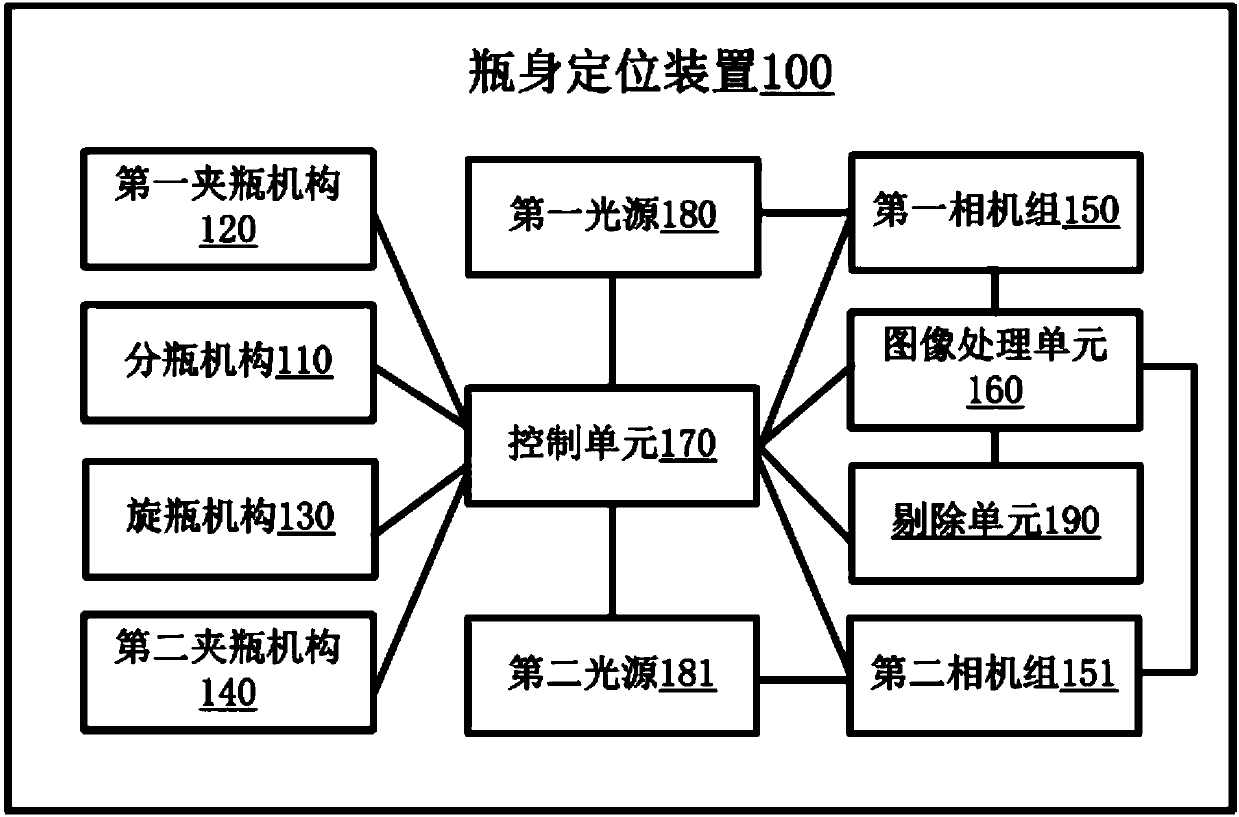

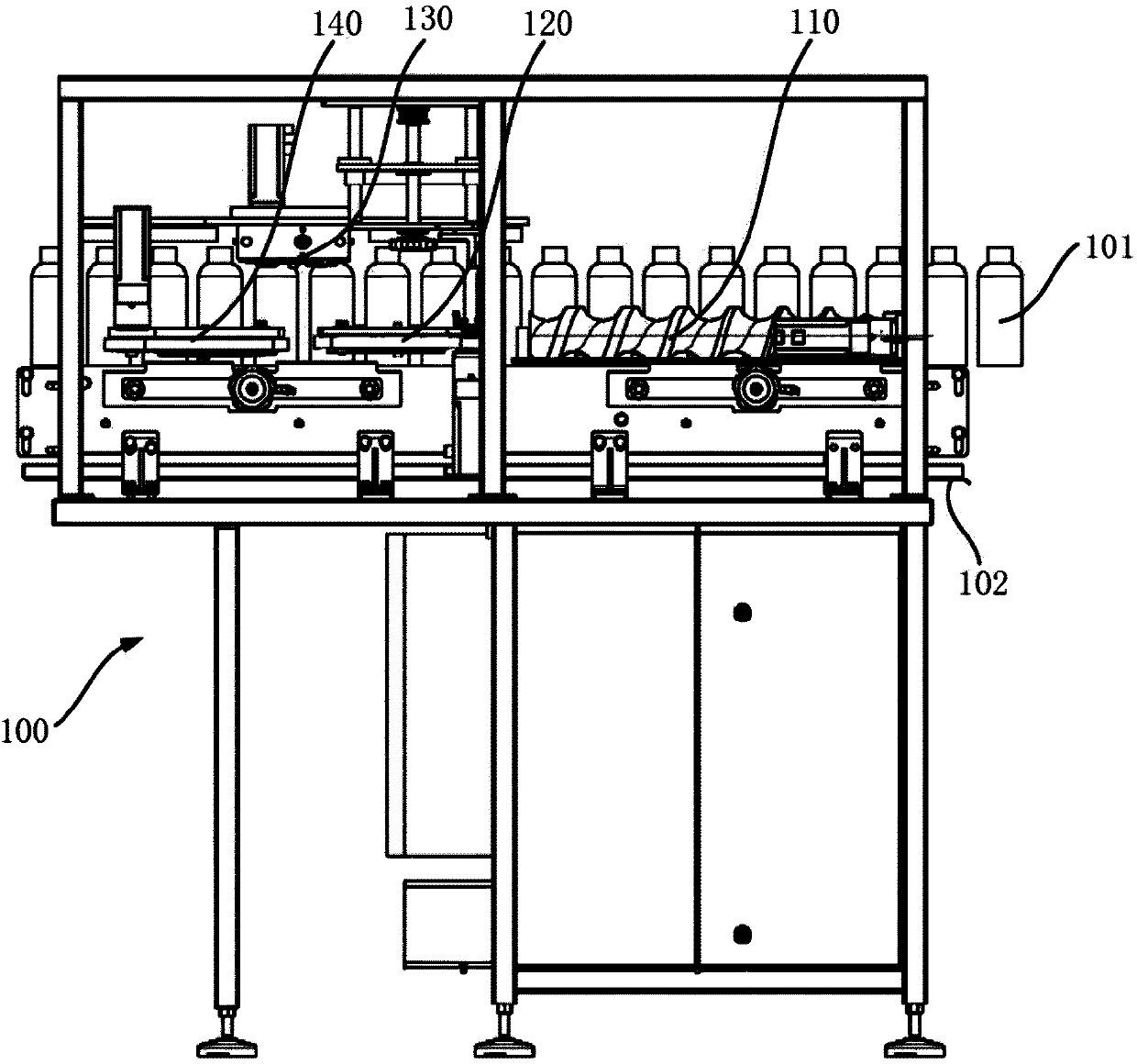

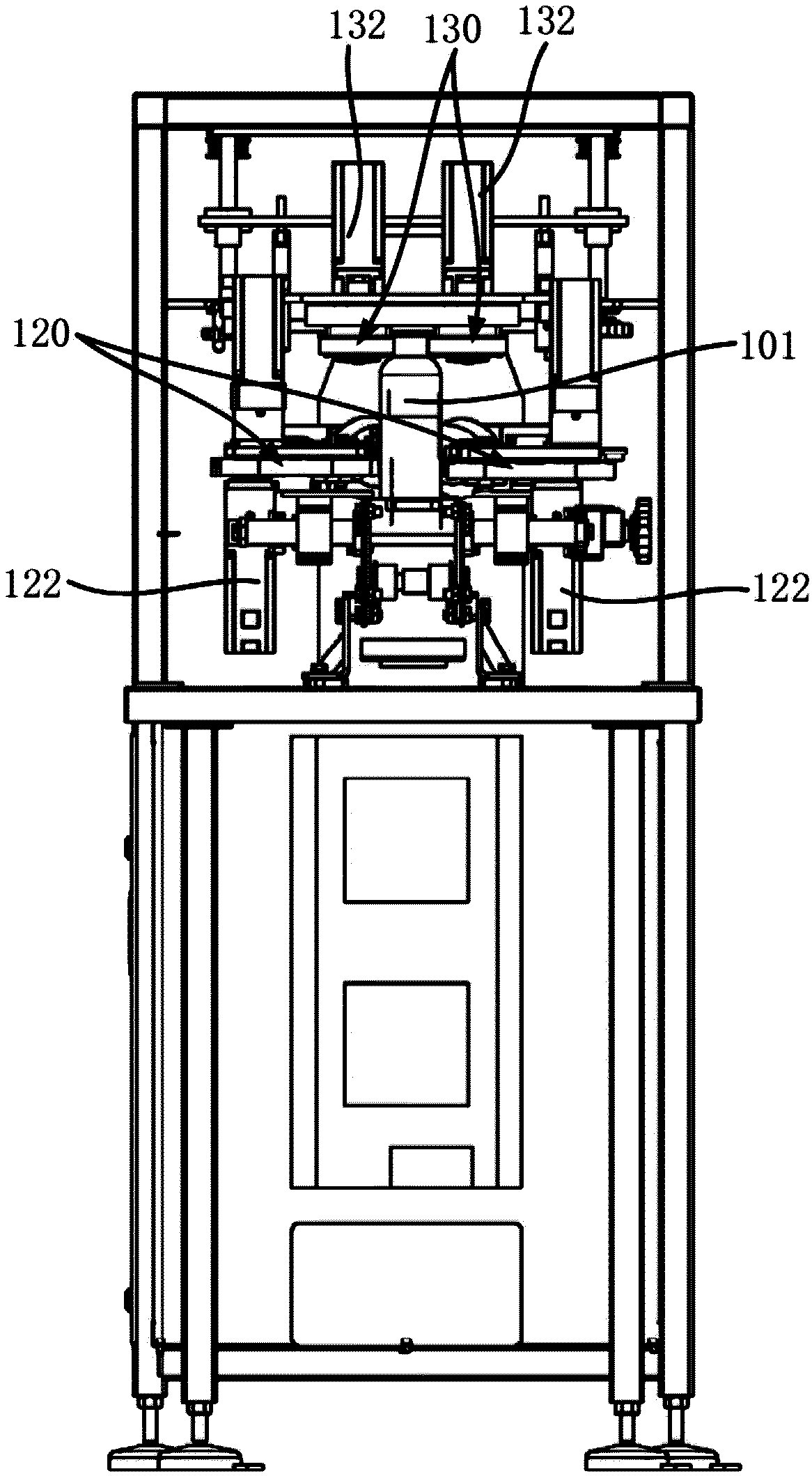

Bottle body positioning device

A technology of positioning device and bottle body, which is applied in the direction of measuring device, conveyor control device, packaging, etc., can solve the problems of difficult to guarantee accuracy, high cost of manipulator, high labor intensity, etc. Effects of Accuracy and Positioning Speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Looking at various bottled beverages, bottled wine or bottled water on the market, the outside of the bottle is all affixed with labels of different shapes and colors. The pattern of the label needs to correspond to the corresponding position of the bottle. Different patterns correspond to different positions of the bottle. For example, the bottle has a protrusion corresponding to a certain pattern on the label. Corresponding to a certain pattern of the label, the label can exactly match the shape of the bottle. This requires that before labeling, it is necessary to adjust the orientation of the bottle to a suitable direction according to the shape of the bottle and the pattern and shape of the label, which is convenient for labeling.

[0044] Since the direction of each bottle is uncertain when it is conveyed on the conveyor chain, the bottles on the production line are constantly moving, and the bottles may also shake during the moving process, so it is difficult to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com