Method for detecting locomotive bearing fault

A technology for bearings and locomotives, applied in the field of locomotive bearing fault detection, can solve the problems of no early warning of locomotive bearing faults, bearings affecting the safe operation of locomotives, bearing failures, etc., to achieve the effect of avoiding unsafe accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

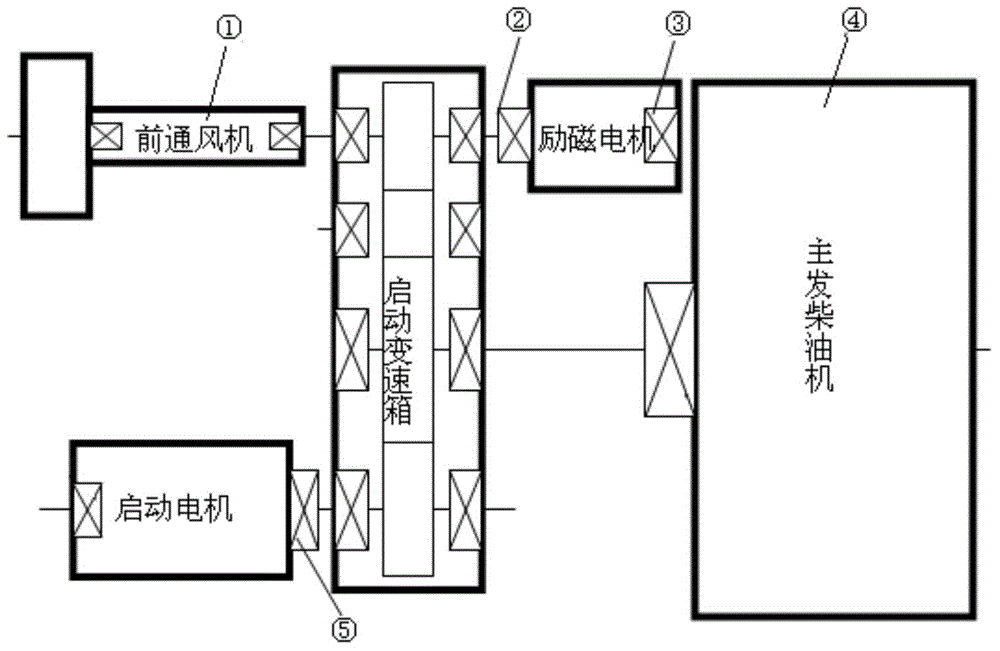

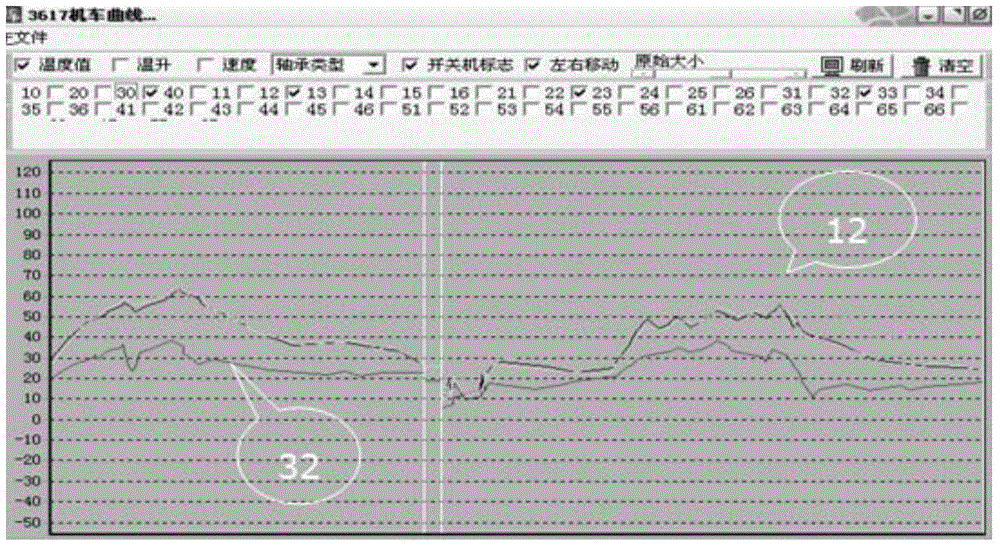

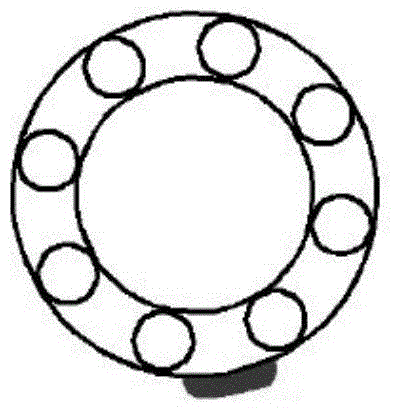

[0065] The invention provides a method for detecting faults of locomotive bearings, which uses a combination of real-time temperature monitoring, vibration monitoring and regular detection to prevent and control the faults of the bearings on the locomotive, thereby ensuring the safe operation of the locomotive.

[0066] Specifically, the method of the present invention includes a method for real-time temperature monitoring of important bearings on the locomotive, and the method for temperature monitoring includes the following steps:

[0067] Using multiple temperature sensors installed at multiple bearing housings of the locomotive to detect the temperature of multiple bearings to obtain the temperature signal of each bearing during the running of the locomotive;

[0068] By processing the real-time temperature signal of each bearing, a series of current bearing temperature values of each bearing are obtained;

[0069] Connect a series of current bearing temperature values ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com