Method for producing laminate

A manufacturing method and technology of laminates, applied in chemical instruments and methods, lamination, controlled lamination, etc., can solve problems such as increased manufacturing cost and material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

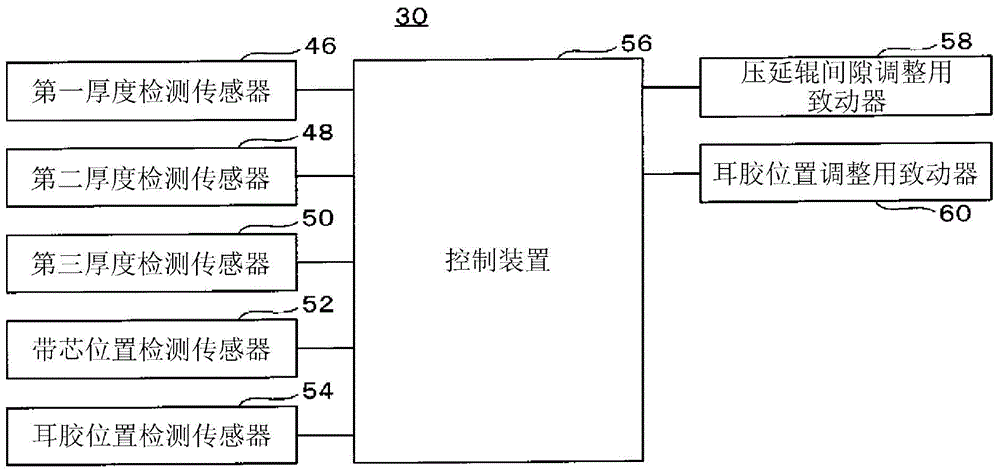

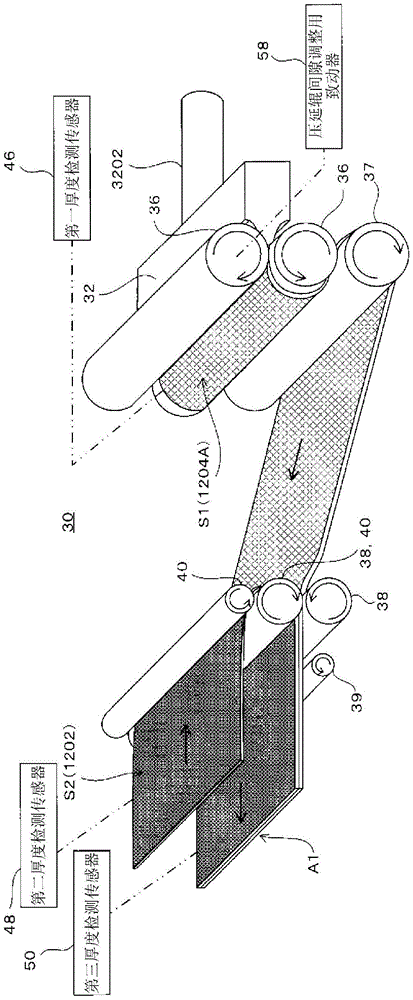

[0024] Next, a method for producing a laminate according to a specific embodiment of the present invention will be described with reference to the drawings.

[0025] In this specific embodiment, the case where the laminate is a tape core, the case where the laminate is a semi-finished product such as an intermediate laminate described below, and the case where the laminate is a final product, namely a conveyor belt, will be described.

[0026] First, the structure of the conveyor belt will be described.

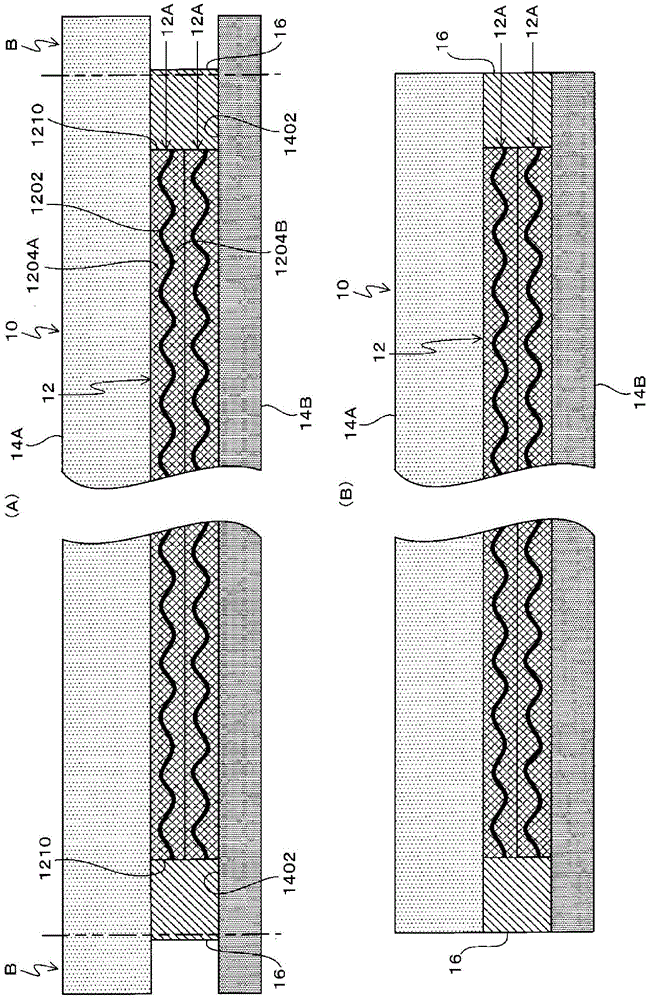

[0027] figure 1 It is a cross-sectional view of the conveyor belt 10 after it is broken on a plane parallel to its width direction. (A) shows the state before cutting the end portions B on both sides, and (B) shows the state after cutting the end portions B on both sides.

[0028] The transmission belt 10 structurally includes a belt core 12 , a first covering rubber 14A, a second covering rubber 14B, and ear gels 16 .

[0029] The belt core 12 is formed by laminating a plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com