A hawthorn automatic pitting and clustering machine

A hawthorn, automatic technology, applied in fruit pitting device, confectionery, confectionery industry, etc., can solve the problems of high labor intensity, low production efficiency, and ineffective safety guarantee, and achieve the solution of high labor intensity, The effect of improving production efficiency and reducing manpower input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

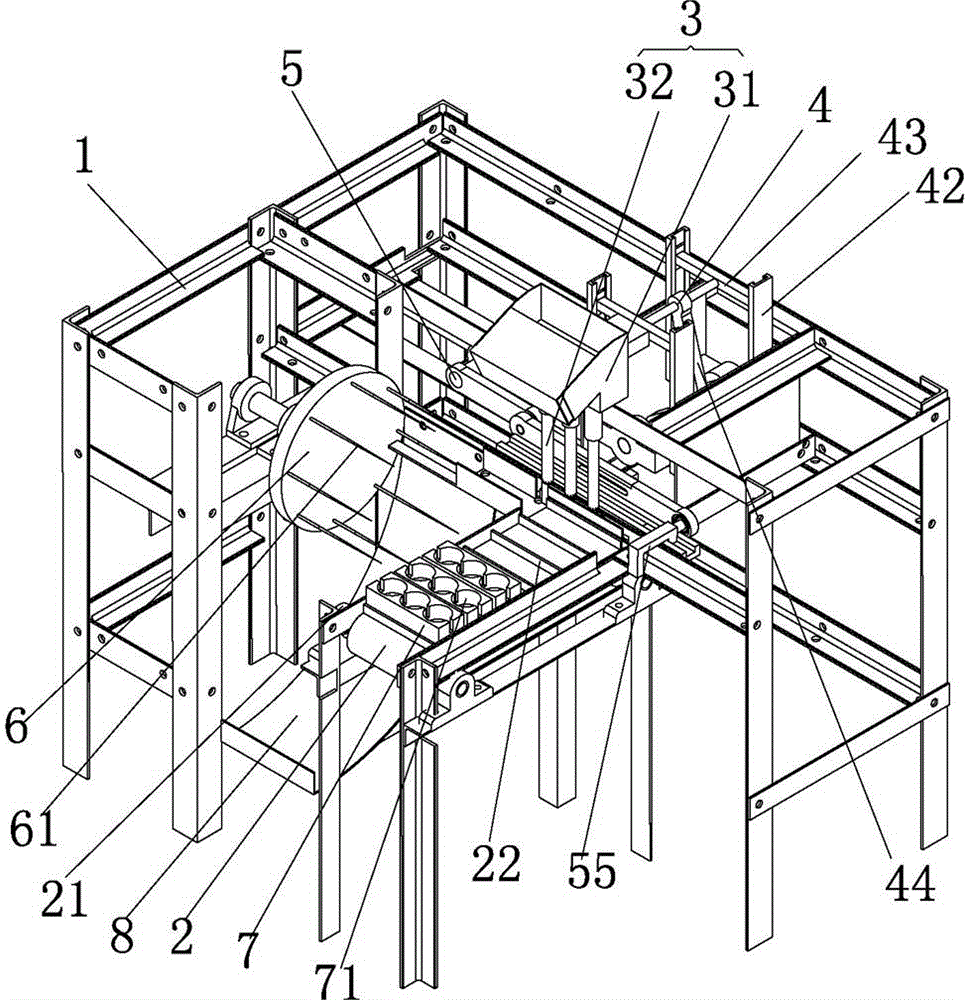

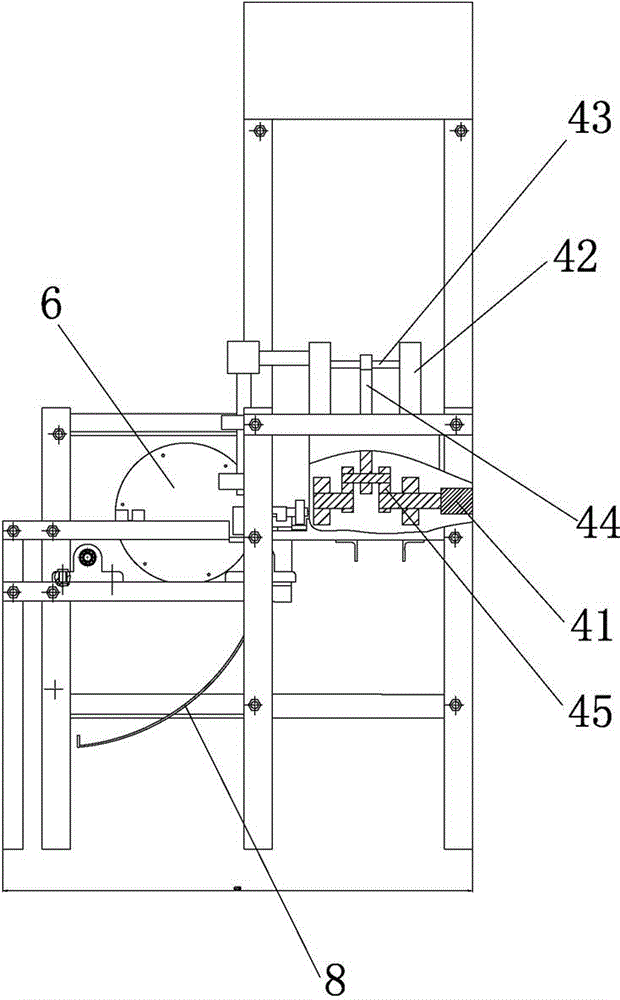

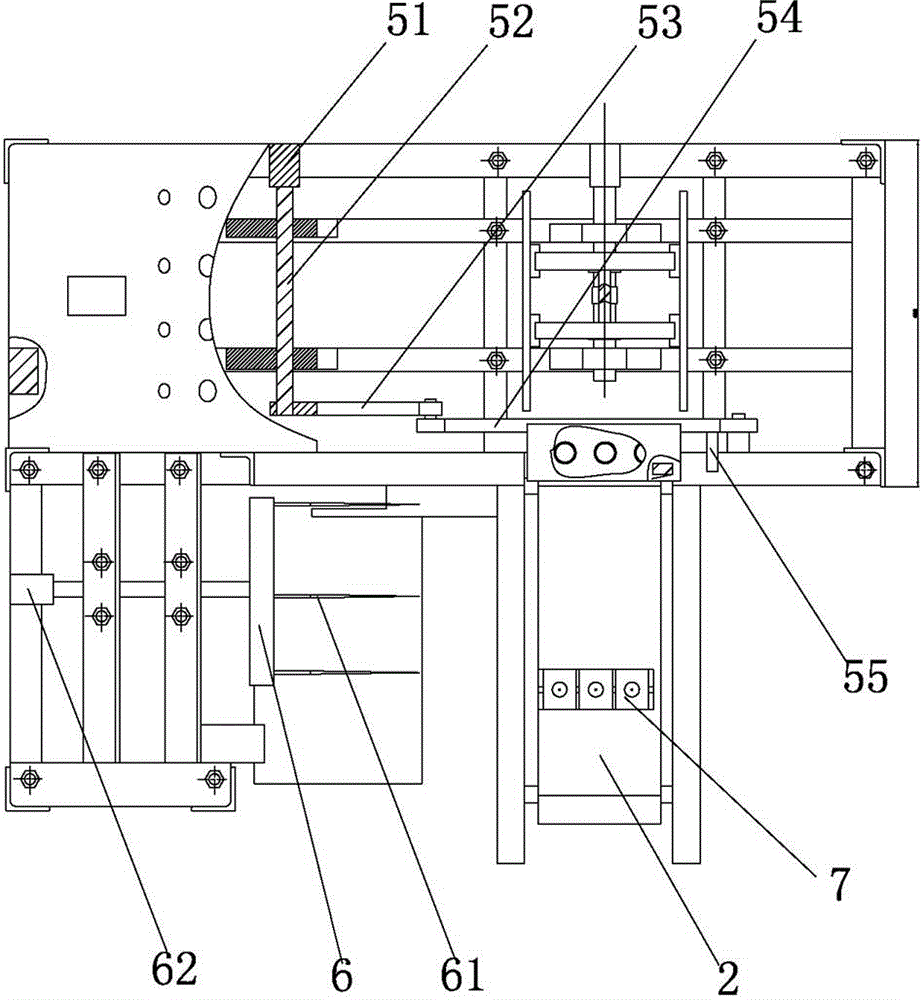

[0025] Please refer to the attached figure 1 To attach Figure 4 Shown, the present invention is a kind of hawthorn automatic pitting and bunching machine, and it is by frame 1, and the conveyor chain mechanism 2 that is installed on the frame 1, the pitting cutter mechanism 3, crank connecting rod mechanism 4, crank slide Several parts such as block mechanism 5 and fixed rotation disc mechanism 6 are formed.

[0026] Wherein, the conveying chain mechanism 2 is driven by a conveying motor 21, on which a hawthorn box 7 is arranged, and drives the hawthorn box 7 to realize the feeding function. The conveying chain mechanism 2 is provided with several baffles 22 , and the baffles 22 abut against and limit the hawthorn box 7 .

[0027] The pitting cutter mechanism 3 is located above one end of the conveying chain mechanism 2 and can be inserted into the hawthorn box 7 . Specifically, the coring cutter mechanism 3 includes a cutter fixing seat 31 and a cutter 32; there are three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com