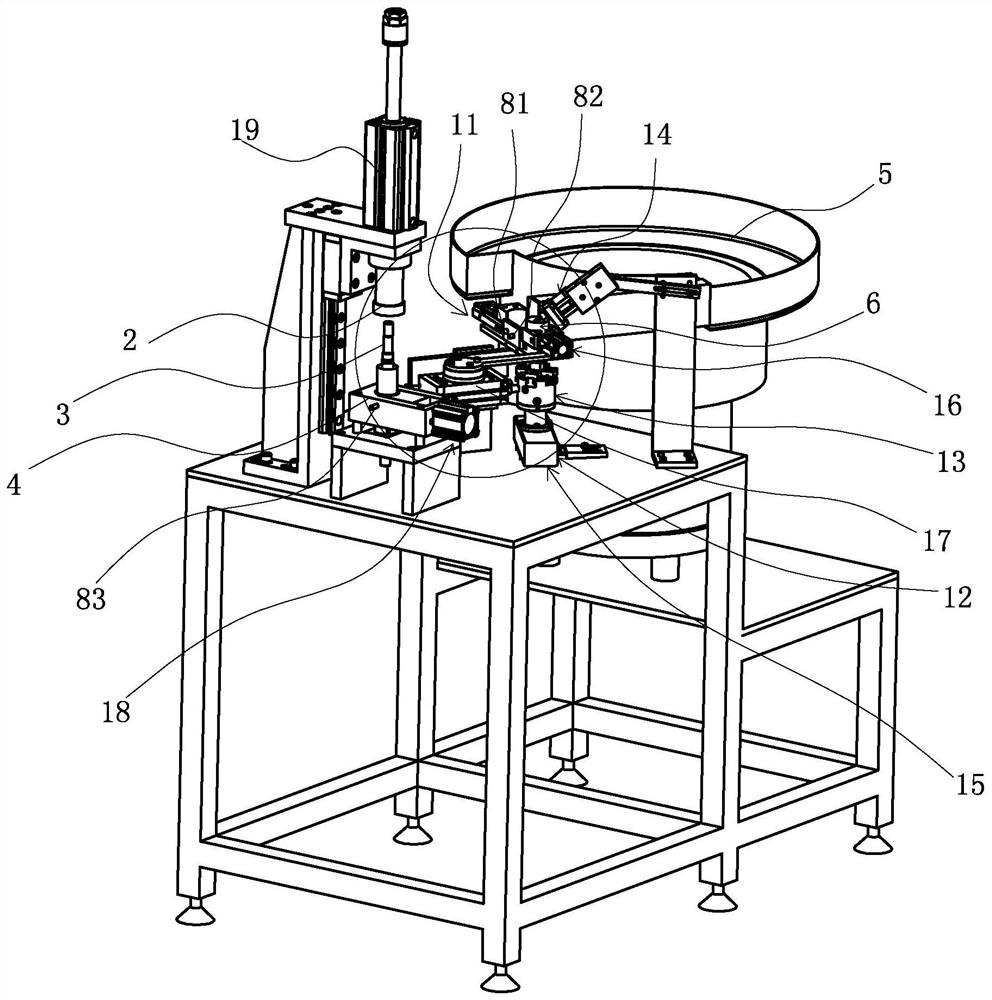

Automated device for feeding, gluing and press-fitting motor rotor magnetic tile sheath

A technology for automatic devices and motor rotors, which is applied to devices for coating liquid on the surface, coatings, metal processing equipment, etc., can solve the problems of time-consuming and laborious assembly, waste of glue, and low efficiency, and achieve fast press-fitting and glue-coating Uniformity, the effect of improving production and assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

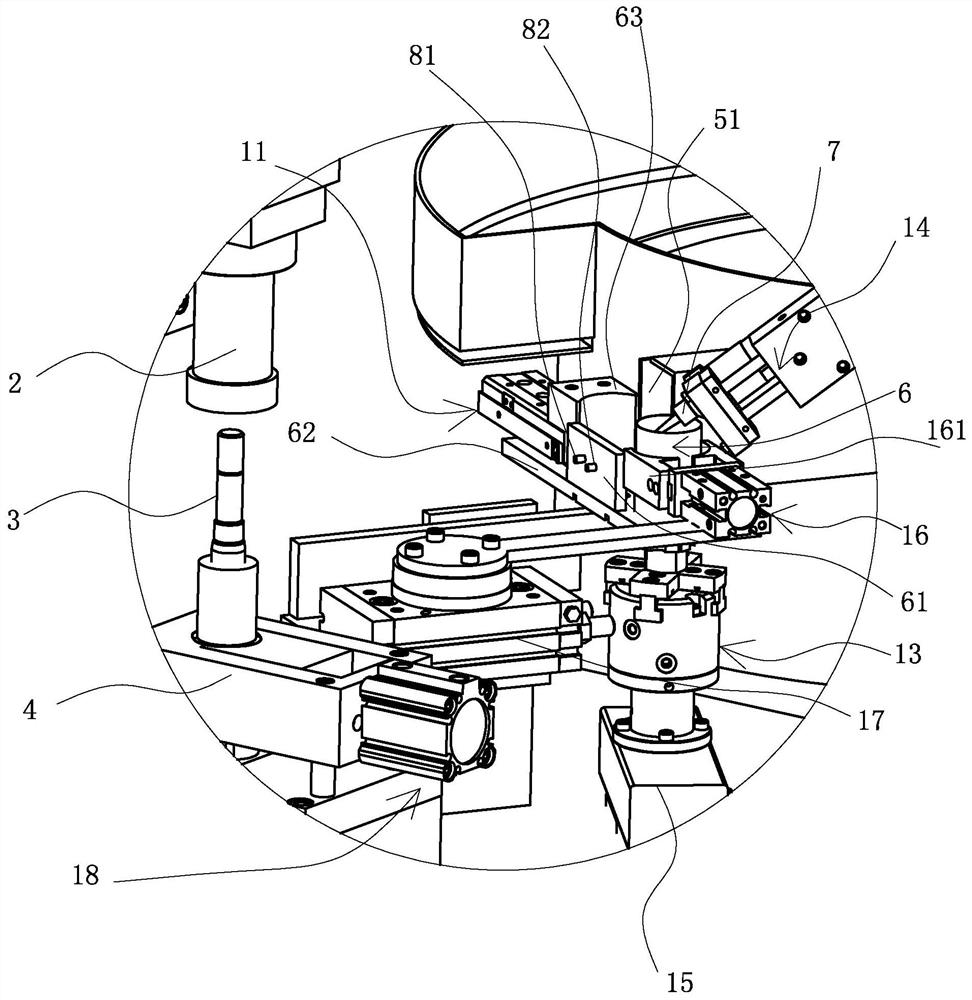

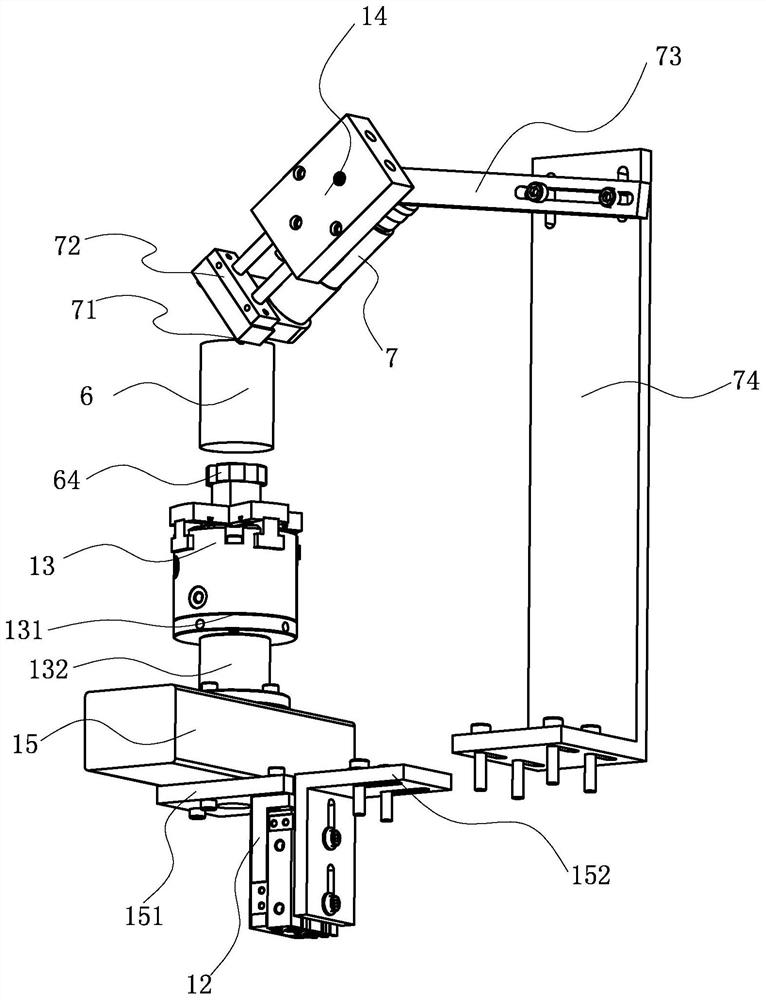

[0031] The first link of the automatic device for feeding, gluing and pressing of the rotor magnetic tile sheath of the motor of the present application is the feeding link of the rotor magnetic tile sheath.

[0032] exist Figure 8and Figure 9 In the middle, the sheath 6 is tubular, and the magnetic tile 31 is adsorbed on the magnetic tile rotor 3. Figure 9 It is shown that the sheath 6 is press-fitted on the magnetic tile rotor 3, and the magnetic tile 31 on the magnetic tile rotor 3 is completely enclosed by the sheath 6. The purpose of the invention of this application is to pass the magnetic tile rotor 3 with the magnetic tile 31 adsorbed therethrough. Feeding, gluing and press-fitting complete the combination of the sheath 6, so that the magnetic tile rotor 3 and the sheath 6 are assembled with glue. On the inner wall of the sheath 6, the magnetic tile rotor 3 is press-fitted into the sheath 6 and the glue can be very evenly coated on the magnetic tile 31, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com