Device for washing shiitake and threading shiitake on drying rod

A technology for washing and drying shiitake mushrooms, which is applied in the fields of application, food processing, food science, etc., can solve the problems of low production efficiency, high labor intensity, and unsatisfactory processing of shiitake mushrooms, so as to improve production efficiency, solve the problems of high labor intensity, The effect of reducing manpower input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

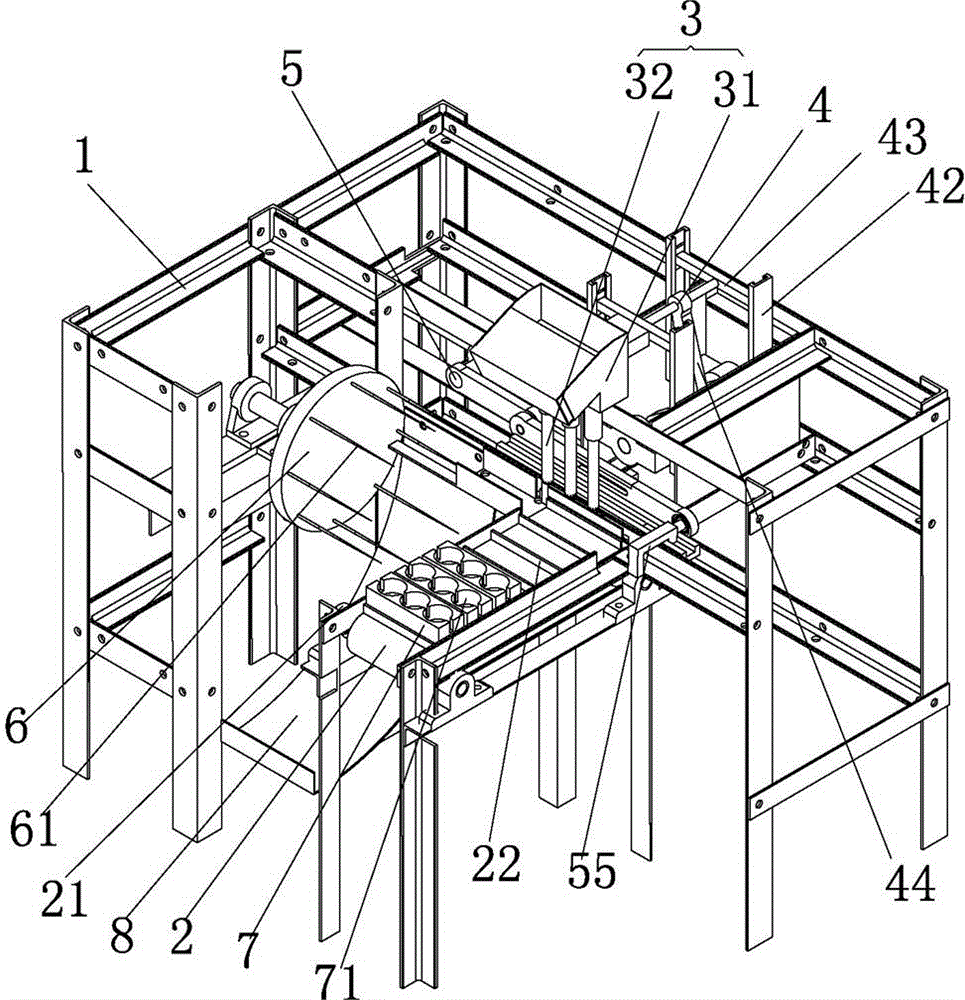

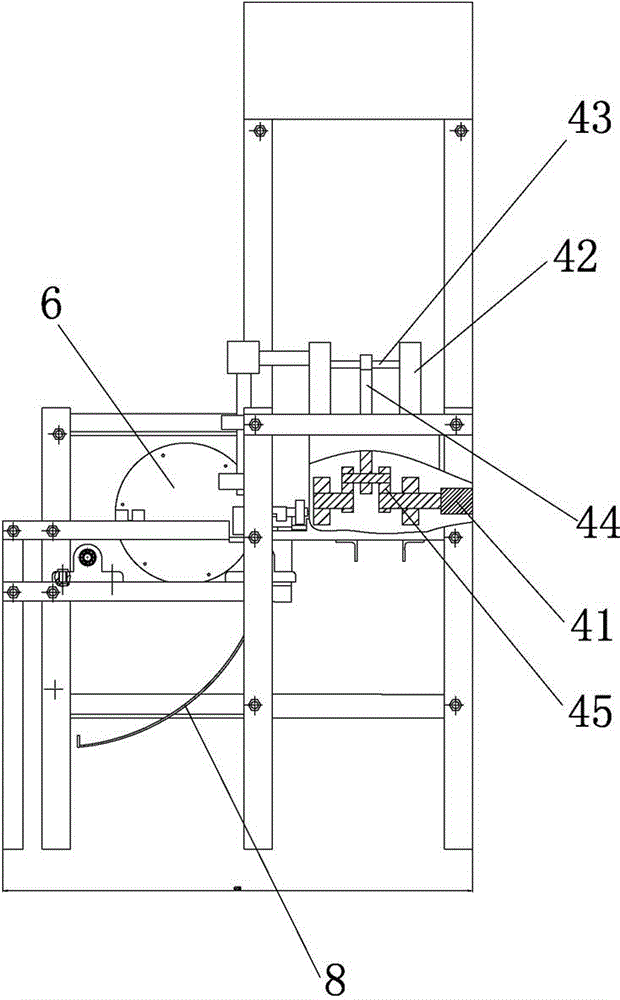

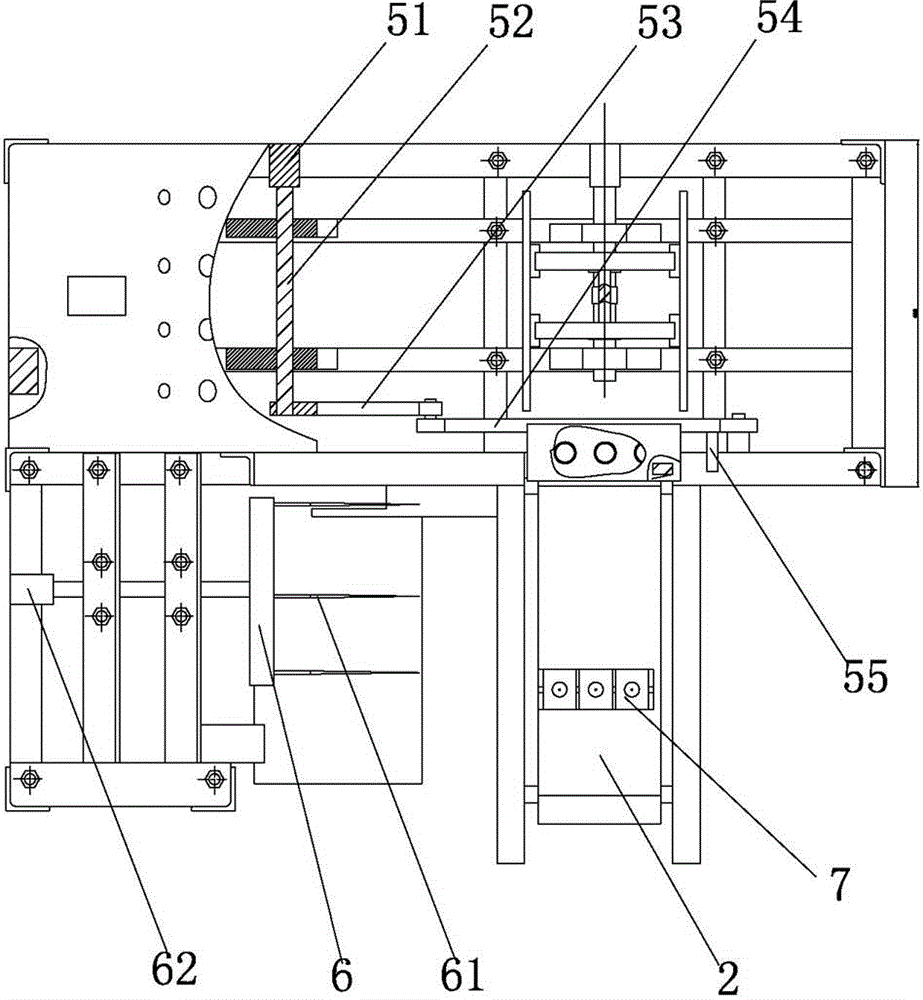

[0021] Please refer to the attached figure 1 to attach Figure 4 As shown, the present invention is a kind of equipment for shiitake mushroom washing and drying rod penetration, which consists of a frame 1, and a conveying mechanism 2 installed on the frame 1, a flushing mechanism 3, a crank linkage mechanism 4, and a pushing mechanism 5 It is made up of several parts such as turntable mechanism 6.

[0022] Wherein, the conveying mechanism 2 is driven by a conveying motor 21, on which the mushroom box 7 is arranged, and drives the mushroom box 7 to realize the feeding function. The conveying mechanism 2 is provided with several baffles 22 , and the baffles 22 abut against and limit the mushroom box 7 .

[0023] The flushing mechanism 3 is located above one end of the conveying mechanism 2, and it can flush the mushrooms in the mushroom box 7. Specifically, the flushing mechanism 3 includes a water tank 31 and a spray head 32 ; the three spray heads 32 are installed at the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com