Springtail dissection tool set and method for manufacturing same

A tool, the technology of springtails, applied in the field of entomological classification research, which can solve the problems of long processing time, damaged insect body, and thick diameter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

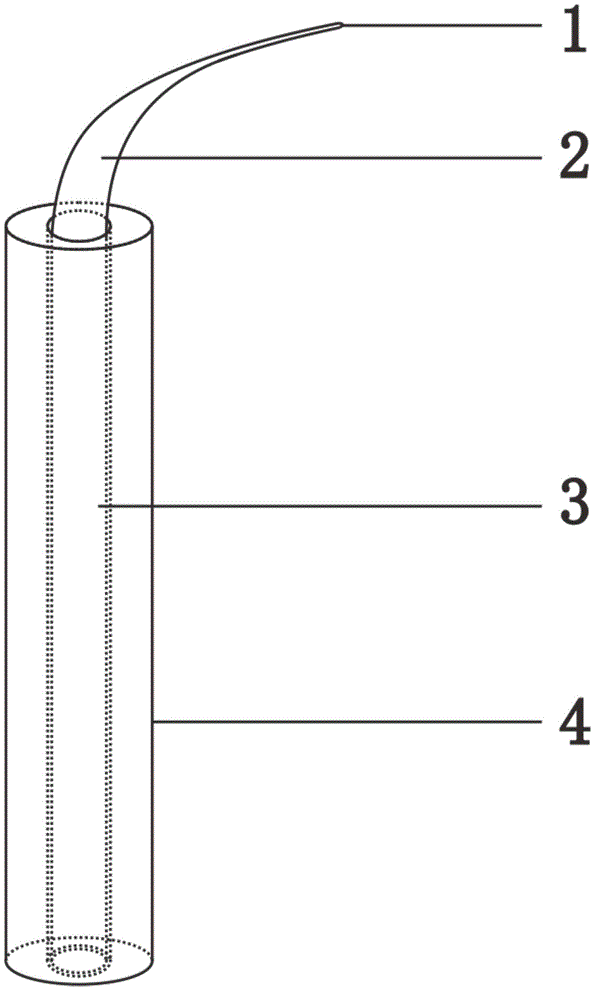

[0023] The dissecting needle in the present invention comprises three parts: a needle (1), a handle (3), and a sleeve (4). Its features are: a tapered needle (1), a curved pipe (2), a cylindrical handle (3) and a cylindrical sleeve (4). The present invention has a nested structure, and the main body (1, 2, 3) of the capillary needle and the cannula (4) can be separated. The needle (1) is tapered, and the closer the tapered needle is to the end of the needle, the smaller the change in diameter is. The direct contact part between the dissection needle and the specimen is the needle head (1). When dissecting the collembola, the operator can dissect by means of the relative movement of a pair of needles (1) in the left and right hands, and can also operate with one hand. The elbow (2) ensures a suitable operating angle (in order to be suitable for exerting force, there should be an angle of 90-120° between the needle head and the needle handle). The sleeve pipe (4) is a long cy...

Embodiment 2

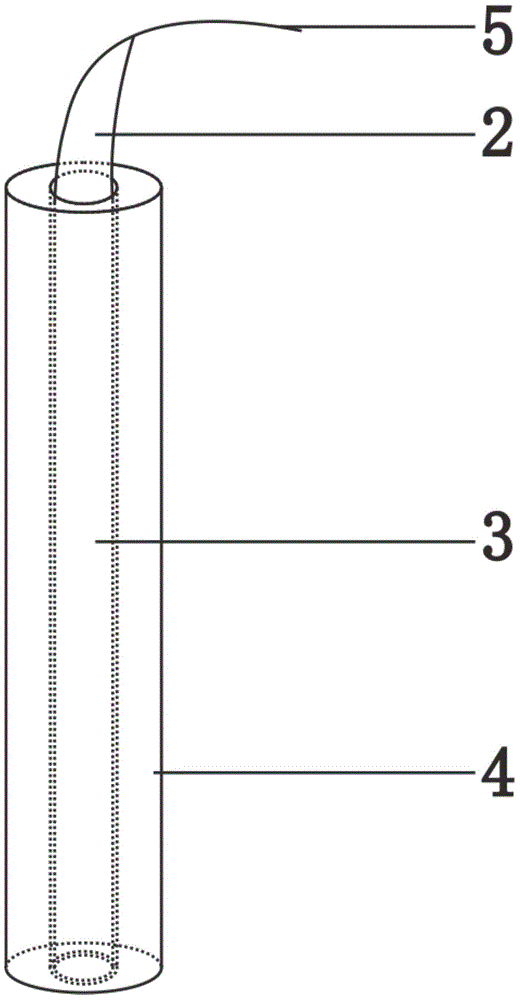

[0025]The bristle filament in the present invention comprises glass fiber filament (5), handle (3), sleeve pipe (4) three parts. The feature is: 0.025-0.035mm glass fiber filament (5), curved pipe (2), cylindrical handle (3) and cylindrical sleeve (4). Production process: melting, wire drawing, selection, modification, cooling, testing, finished product. When making the bristle filament, melt one end of the capillary at the flame of an alcohol lamp, clamp the melted end with tweezers and pull it quickly to make an uninterrupted glass fiber with a length of about 300mm. Measure the fiber with a spiral micrometer, select a section with a diameter of 0.025-0.035mm close to the main body of the capillary, and remove the remaining part. Thereafter, rely on the softening effect of the flame on the capillary to shorten the excess glass fiber to make the fiber filament about 10mm long, and nest the finished dissecting needle body in the plastic sleeve. If the wire drawing effect is ...

Embodiment 3

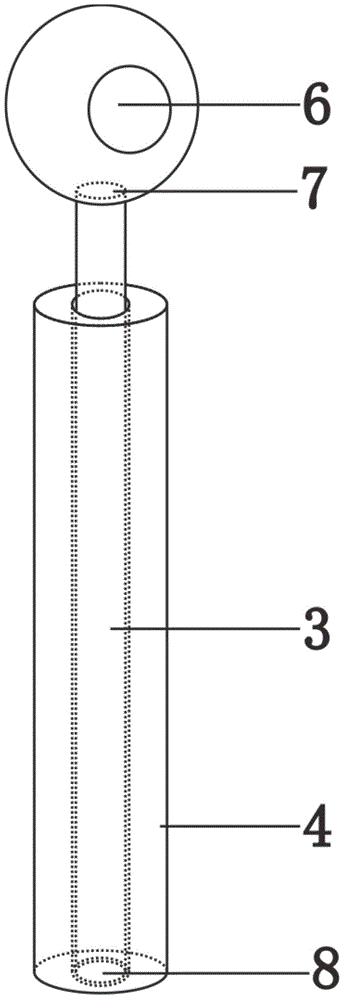

[0027] The aspirator in the present invention comprises three parts: a thin-walled glass capsule (6), a handle (3), and a sleeve (4). The feature is: an enlarged hollow thin-walled glass capsule (6), a curved pipe (2), a cylindrical handle (3) and a cylindrical sleeve (4). There is an approximately circular inlet (7) on the side of the bag, and an opening (8) communicated with the outside world at the tail of the aspirator. Production process: melting, ventilation, wall breaking, modification, testing, finished product. When making an aspirator, one end of the capillary is melted at the flame of an alcohol lamp, and air is blown on the other side of the capillary to expand the melted part and form a thin-walled vesicle. When the thin-walled vesicle is burst by the gas, the burst part is a nearly circular inlet. Thereafter, the finished absorber body can be nested in the plastic sleeve. When pipetting the worm body soaked in the transparent agent, just align the round inlet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com