Aerogel anti-noise earplug

An anti-noise and airgel technology, applied in the field of airgel, can solve the problems of poor sound insulation effect of earplugs and achieve good sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The shape of the airgel anti-noise earplug 100 of one embodiment is cylindrical, such as figure 1 As shown, a main body 110 is included. The main body 110 includes a section of sound insulation, that is, the entire main body 110 is a section of sound insulation. And the whole body 110 is made of polyurea airgel. The polyurea airgel of the airgel anti-noise earplug 100 of this embodiment has a uniform density and only has one specification, specifically 0.08g / cm 3 . In addition, the porosity of the polyurea airgel of the airgel noise-proof earplugs 100 of this embodiment is 92.5%, and the specific surface area is 198.6m 2 / g.

[0025] The airgel anti-noise earplug 100 of embodiment 1 is a soft earplug, because the polyurea nanofibers in the polyurea airgel layer and the micro-nano-level porous structure self-assembled by nanoparticles can effectively attenuate the sound wave energy, therefore, implement The airgel anti-noise earplug 100 of Example 1 can achieve the ...

Embodiment 2

[0027] The difference between this embodiment and Embodiment 1 is that the airgel anti-noise earplugs of this embodiment are hard earplugs, and the density of the polyurea airgel forming the airgel anti-noise earplugs is 0.4g / cm 3 . At the same time, the porosity of the polyurea airgel of the airgel anti-noise earplug of the present embodiment is 72.7%, and the specific surface area is 72.9m 2 / g.

[0028] The airgel anti-noise earplug of embodiment 2 is hard earplug, because the polyurea nanofiber in the polyurea airgel layer and the self-assembled micro-nano-level porous structure of nanoparticle can effectively attenuate sound wave energy, therefore, embodiment The airgel noise-proof earplugs of 2 can achieve the effect of sound insulation and noise reduction, and the sound insulation effect is good.

Embodiment 3

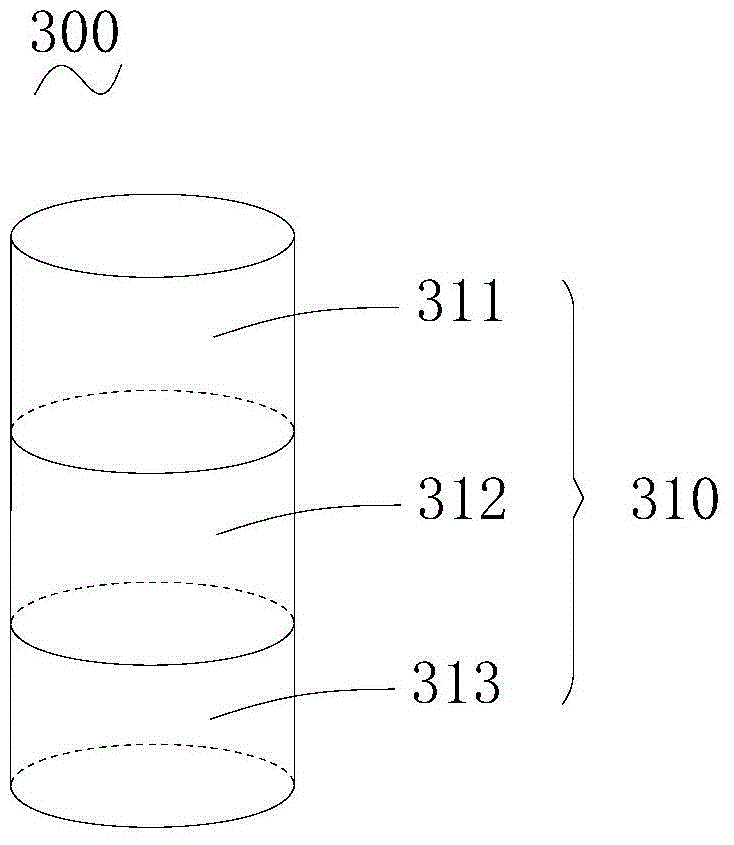

[0030] The shape of the airgel anti-noise earplug 300 of one embodiment is cylindrical, such as figure 2 As shown, a main body 310 is included. The main body 310 includes three sound-insulating sections, specifically a first sound-insulating section 311 , a second sound-insulating section 312 and a third sound-insulating section 313 , and two adjacent sound-insulating sections are connected by bonding. And the first sound insulation section 311 , the second sound insulation section 312 and the third sound insulation section 313 are all made of polyurea airgel, but the density of the polyurea airgel of two adjacent sound insulation sections is different. Specifically, the density of the polyurea airgel in the first sound insulation section 311 and the third sound insulation section 313 is both 0.08g / cm 3 , the density of polyurea airgel in the second sound insulation section 312 is 0.4g / cm 3 . In addition, the porosity of the polyurea airgel in the first sound insulation se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com