Pulp molded skeleton for automobile cavity filling material and preparation method thereof

A filling material and pulp molding technology, which is applied in papermaking, paper, paper coating, etc., can solve the problems of reducing the weight of the whole vehicle and the quality of filling materials for automobiles, and achieve the effect of simple processing technology and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

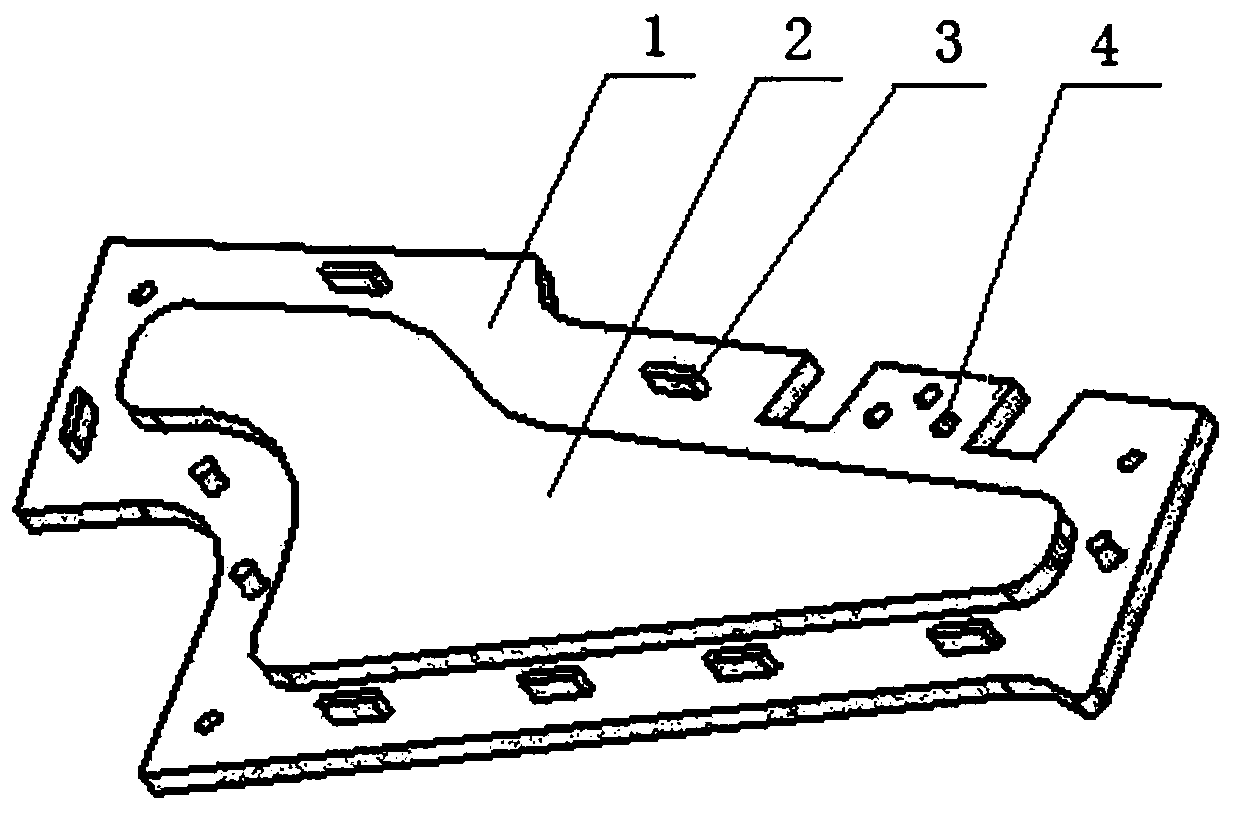

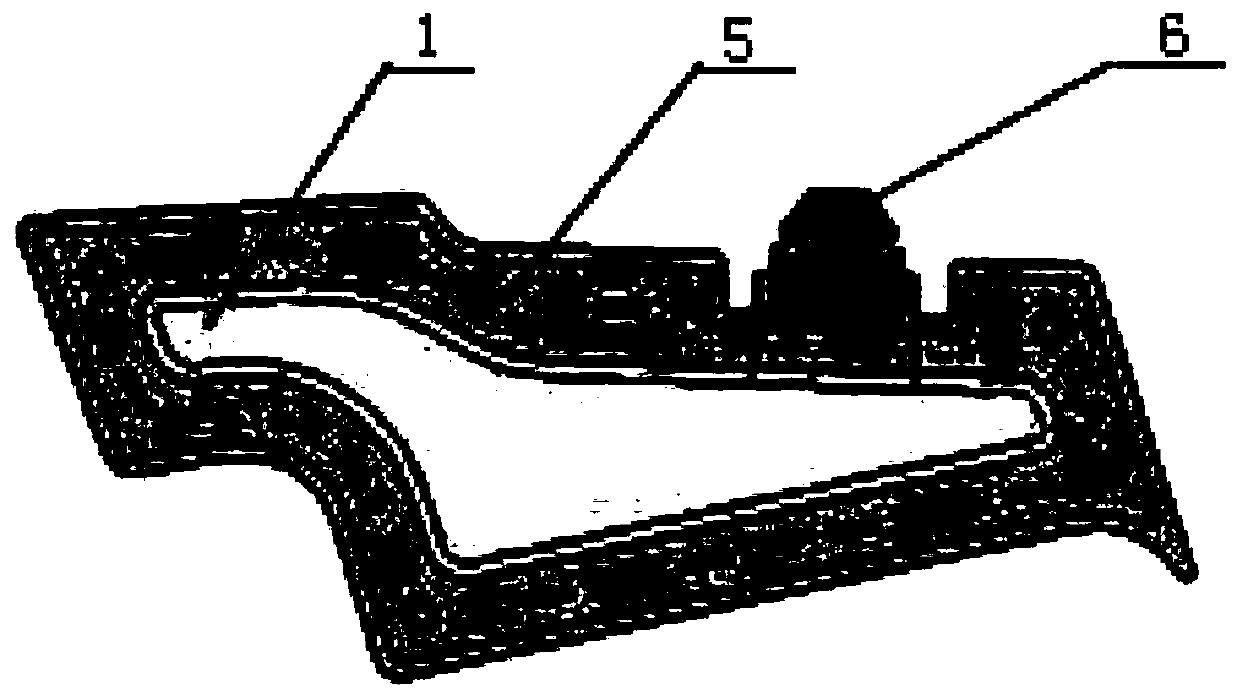

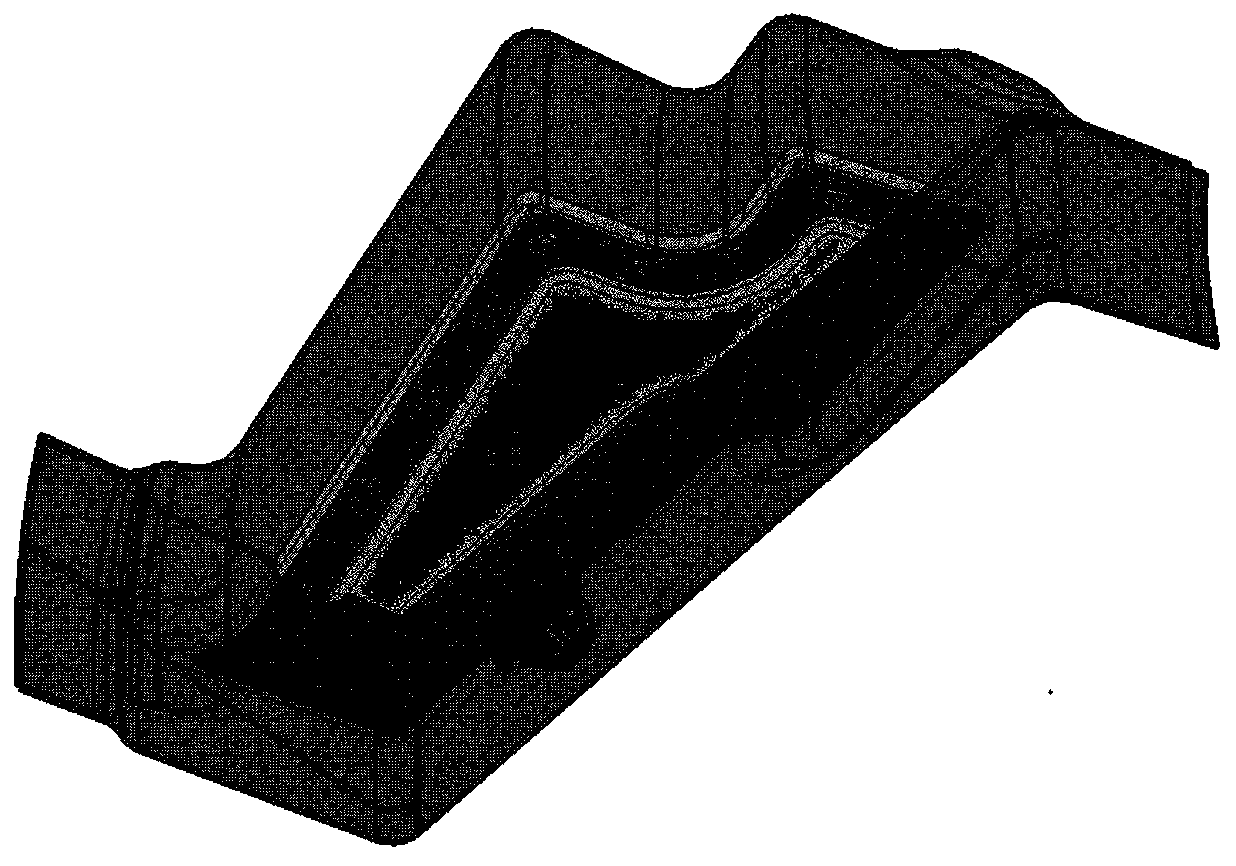

Image

Examples

Embodiment 1

[0033] A kind of pulp molded skeleton that is used for automobile cavity filling material, preparation method comprises the following steps:

[0034] 1 Crushing raw materials: 100 kg of recovered waste paper is pulverized and ground to obtain pulp fibers. Then pour the pulp cellulose into the beater, then add deionized water, stir for 30-40 minutes, and after stirring, let it stand at room temperature for 25 minutes to obtain a uniformly mixed liquid.

[0035] 2 Mixing: Add 10kg of starch, 2kg of 4% polyvinyl alcohol solution, 3kg of 6% aqueous acrylic resin solution, 1000kg of deionized water, 50kg of rosin, 30kg of neoprene latex, 0.6kg of polymethylhydrogen siloxane, etc. into the mixed liquid The raw materials are stirred in a beater for 30-40 minutes, and mixed evenly to obtain a secondary mixed liquid.

[0036] 3 Compression molding: Under the conditions of a molding machine at 100°C and 20 minutes, the secondary mixed liquid is molded through a water mold to form a pre...

Embodiment 2

[0048] A kind of pulp molded skeleton that is used for automobile cavity filling material, preparation method comprises the following steps:

[0049] 1 Crushing raw materials: 100 kg of recovered waste paper is pulverized and ground to obtain pulp fibers. Then pour the pulp cellulose into the beater, then add deionized water, stir for 30-40 minutes, and after stirring, let it stand at room temperature for 25 minutes to obtain a uniformly mixed liquid.

[0050] 2 Mixing: Add 15kg of starch, 3kg of 4% polyvinyl alcohol solution, 4kg of 6% water-based acrylic resin solution, 1000kg of deionized water, 60kg of rosin, 40kg of neoprene latex, 1kg of dimethyl silicone oil and other raw materials into the mixed liquid in the beater Stir in medium for 30-40min, and mix evenly to obtain secondary mixed liquid.

[0051] 3 Compression molding: Under the conditions of a molding machine at 100°C and 20 minutes, the secondary mixed liquid is molded through a water mold to form a preliminary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com