Self-circulation remaining fog processing system

A processing system and vacuum technology, applied in the direction of dust removal, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems affecting the work of other stations, waste, etc., and achieve the effect of saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

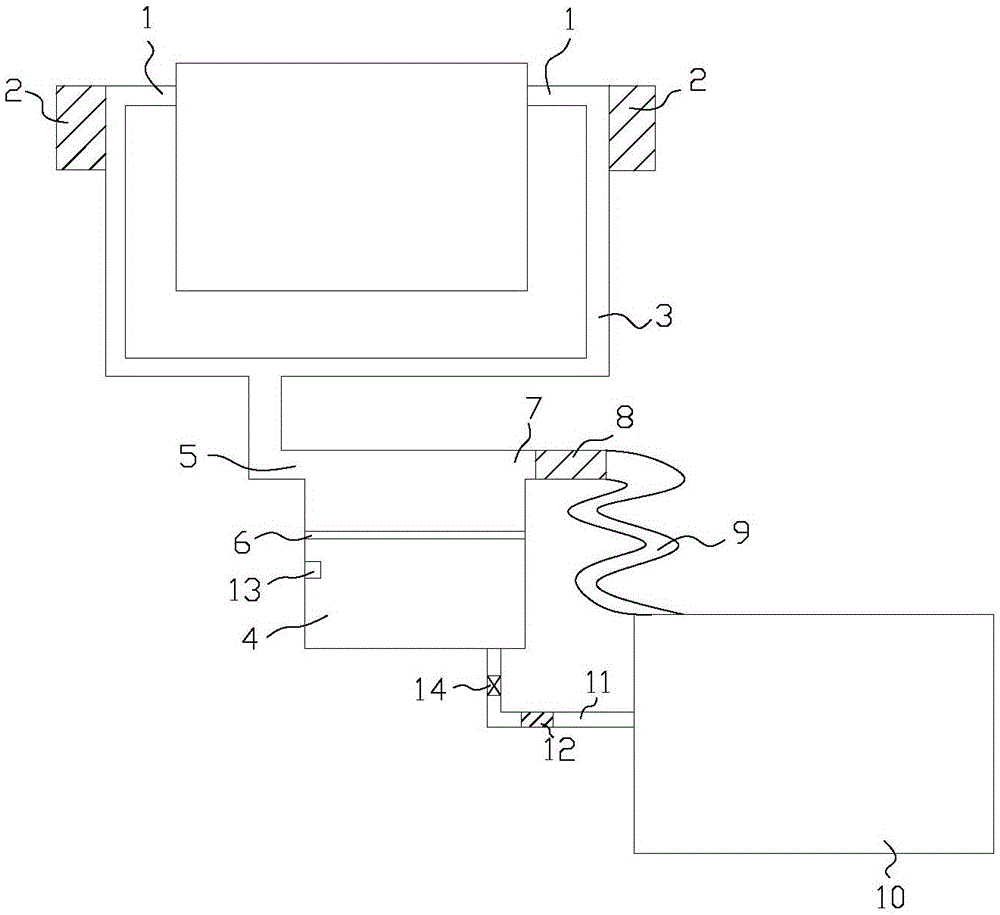

[0011] The present invention will be further described below with reference to the accompanying drawings and in conjunction with the embodiments.

[0012] The residual mist treatment system of the present invention is applied to the bearing cleaning line, specifically to the atomization and oiling station on the bearing cleaning line. The so-called atomizing oiling station is used to spray anti-rust oil on the cleaned bearing parts to ensure that the bearing parts have good anti-rust effect when they are used in the future. The atomization and oiling area in the prior art is generally carried out in a relatively airtight atomization and oiling room. During work, the bearing parts are driven by the mechanical arm or the conveyor belt through the atomization and oiling room, and the mist installed in the atomization and oiling room The anti-rust oil is sprayed out from the chemical nozzle, and the bearing parts are evenly oiled. Although the atomization and oiling chamber is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com