Profiled-blank continuous casting machine and profiled-blank continuous casting secondary cooling water blowing method

A special-shaped billet continuous casting and secondary cooling technology, applied in the field of metallurgy, can solve the problems of uneven cooling and quality defects of the billet, and achieve the effect of reducing the surface temperature deviation, improving the quality of the billet and continuous casting productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The above-mentioned and other technical features and advantages of the present invention will be described in more detail below in conjunction with the embodiments.

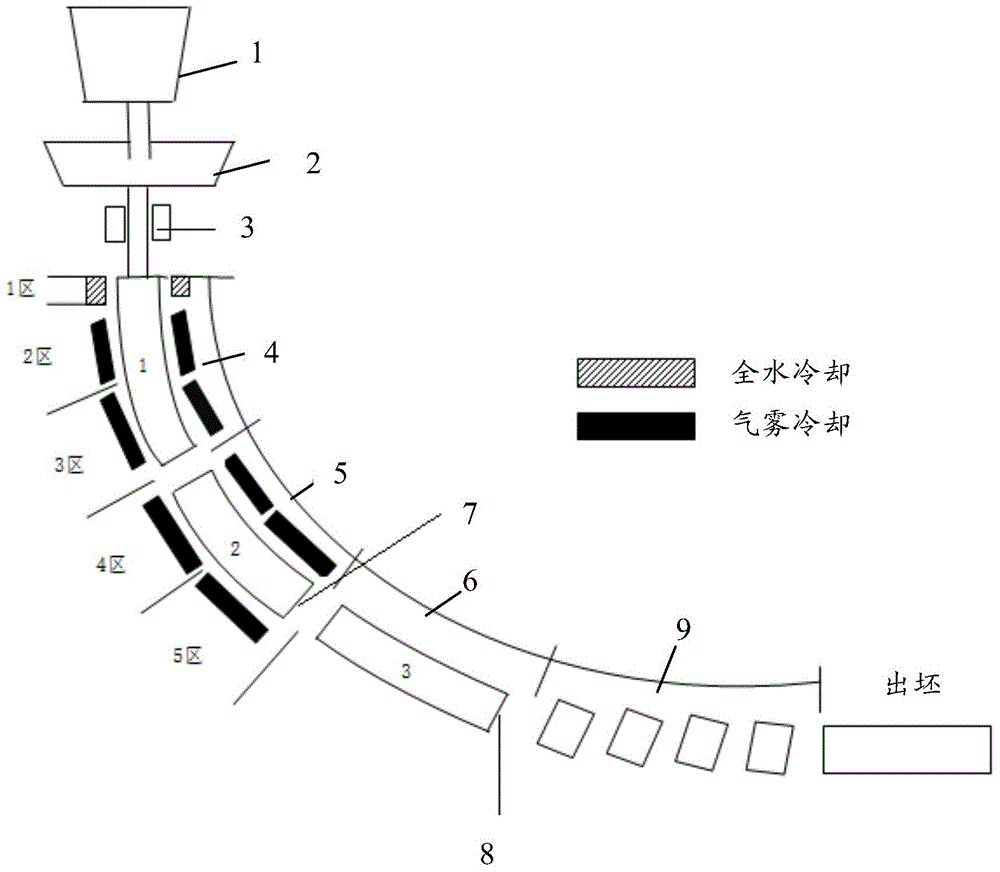

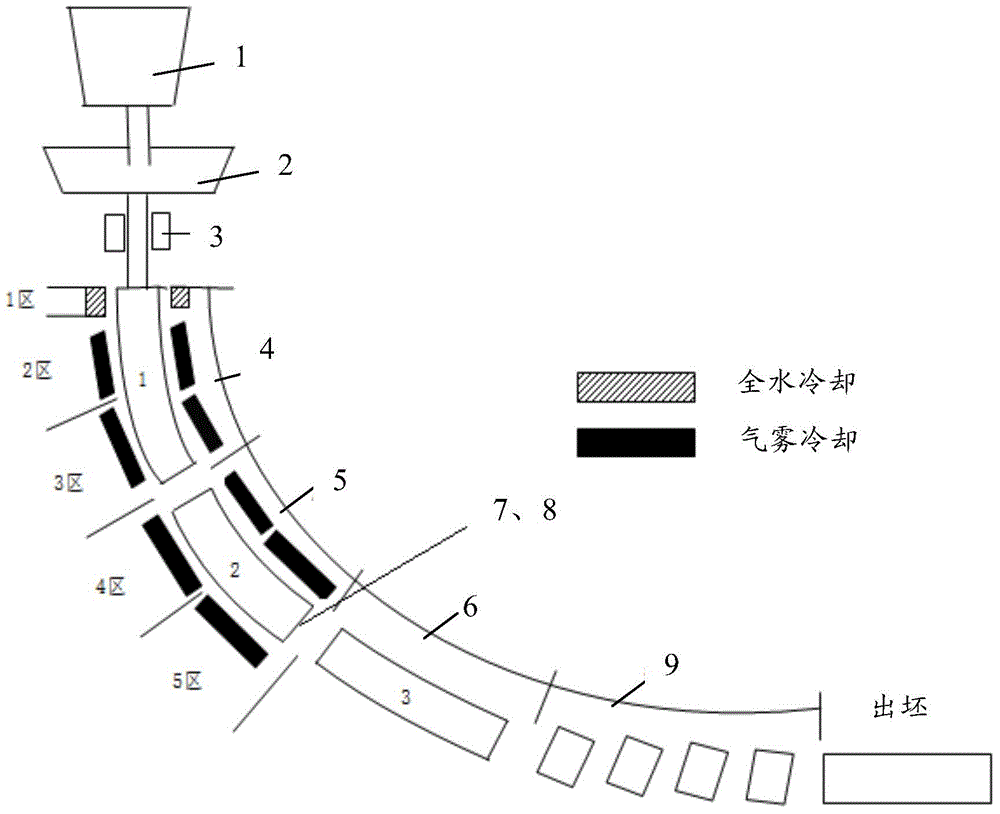

[0018] figure 1 It is a structural schematic diagram of an existing profiled billet continuous casting machine, including sequentially connected steel ladle 1, tundish 2, crystallizer 3, and fan-shaped I section 4, fan-shaped II section 5, and fan-shaped III section 6 of the cooling chamber. The installation positions of the original water blowers 7 and 8 in the second cold room are respectively at the end of section II of each flow and the end of the guide section, the casting lengths are 9m and 12m respectively, and the distance between the water blowers 7 and 8 is The surface is 15-18mm, and the distance from the billet surface is relatively far. The medium used is compressed air, and the working pressure of the medium is 0.35-0.42 kg, which is relatively small. During the operation, it was found that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com