Method for preparing thin film by laser precision molding, molding device and demoulding device

A molding and thin-film technology, which is applied in the field of thin-film preparation by laser precision molding, can solve problems such as difficulty in demoulding thin-film parts, and achieve the effects of fast preparation speed, good application prospects, and small surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

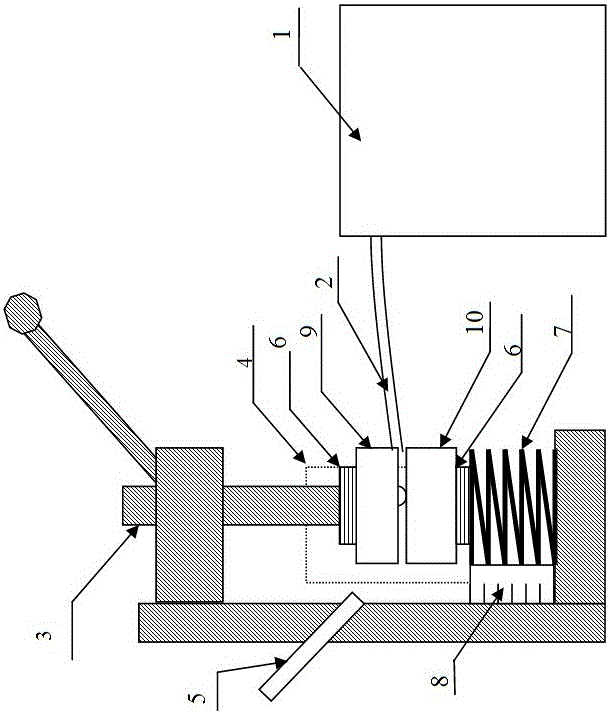

[0073] Example 1 Preparation of Aluminum Thin Film

[0074] 1. Glass mold preparation

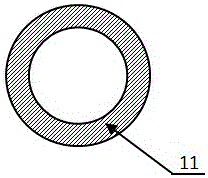

[0075] Sapphire glass with a diameter of 10mm and a thickness of 8mm is processed, polished on both sides, and the surface quality is 60 / 40. Take a piece of sapphire glass and plate a TiN / Ti thin film with a thickness of 5 microns, an outer diameter of 10 mm and an inner diameter of 7 mm on a magnetron sputtering coating machine, and record the coated sapphire glass as the upper mold. Another piece of polished glass is taken as the lower mold, and the upper mold and the lower mold form the molding mold.

[0076] 2. Raw material preparation

[0077] Cut aluminum into small particles, and weigh 100 micrograms of aluminum particles with a balance with a minimum sensitivity of 10 micrograms. Aluminum pellets are placed in the central area of the lower mold.

[0078] 3. Sample installation

[0079] Install compression scales, springs, heat insulation gaskets, lower molds, aluminum particl...

Embodiment 2

[0098] Example 2 Preparation of Tin Film

[0099] 1. Glass mold preparation

[0100] Sapphire glass with a diameter of 10mm and a thickness of 8mm is processed, polished on both sides, and the surface quality is 60 / 40. Take a piece of sapphire glass and plate a TiN / Ti thin film with a thickness of 5 microns, an outer diameter of 10 mm and an inner diameter of 7 mm on a magnetron sputtering coating machine, and record the coated sapphire glass as the upper mold. Another piece of polished glass is taken as the lower mold, and the upper mold and the lower mold form the molding mold.

[0101] 2. Raw material preparation

[0102] Cut tin into small particles, and weigh 250 micrograms of tin particles with a balance with a minimum sensitivity of 10 micrograms. Tin particles are placed in the central area of the lower mold.

[0103] 3. Sample installation

[0104] Install compression scales, springs, heat insulation gaskets, lower molds, aluminum particles, upper molds, heat i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com