A control method of a dual optical path laser online flight coding system

A control method and dual optical path technology, applied in the field of laser marking, can solve the problems of galvanometer control errors and out-of-synchronization, and achieve the effects of ensuring quality, improving efficiency, and avoiding missing codes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

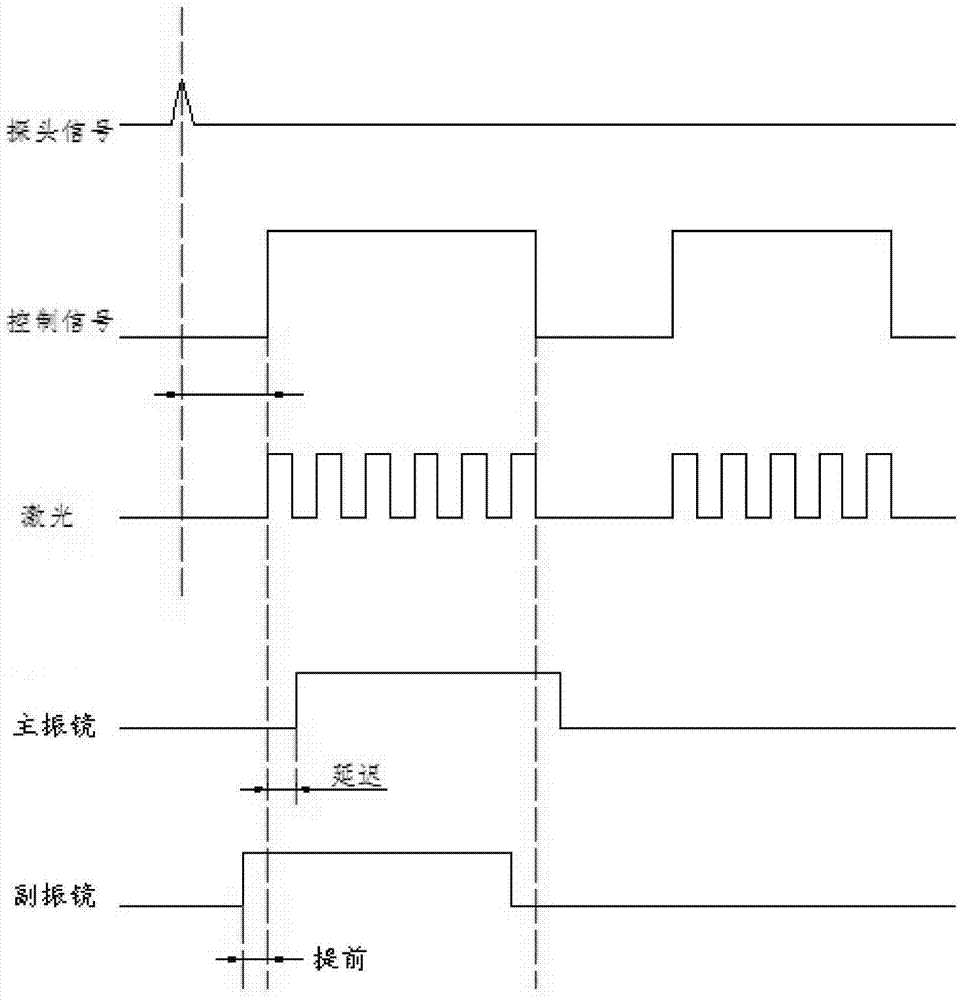

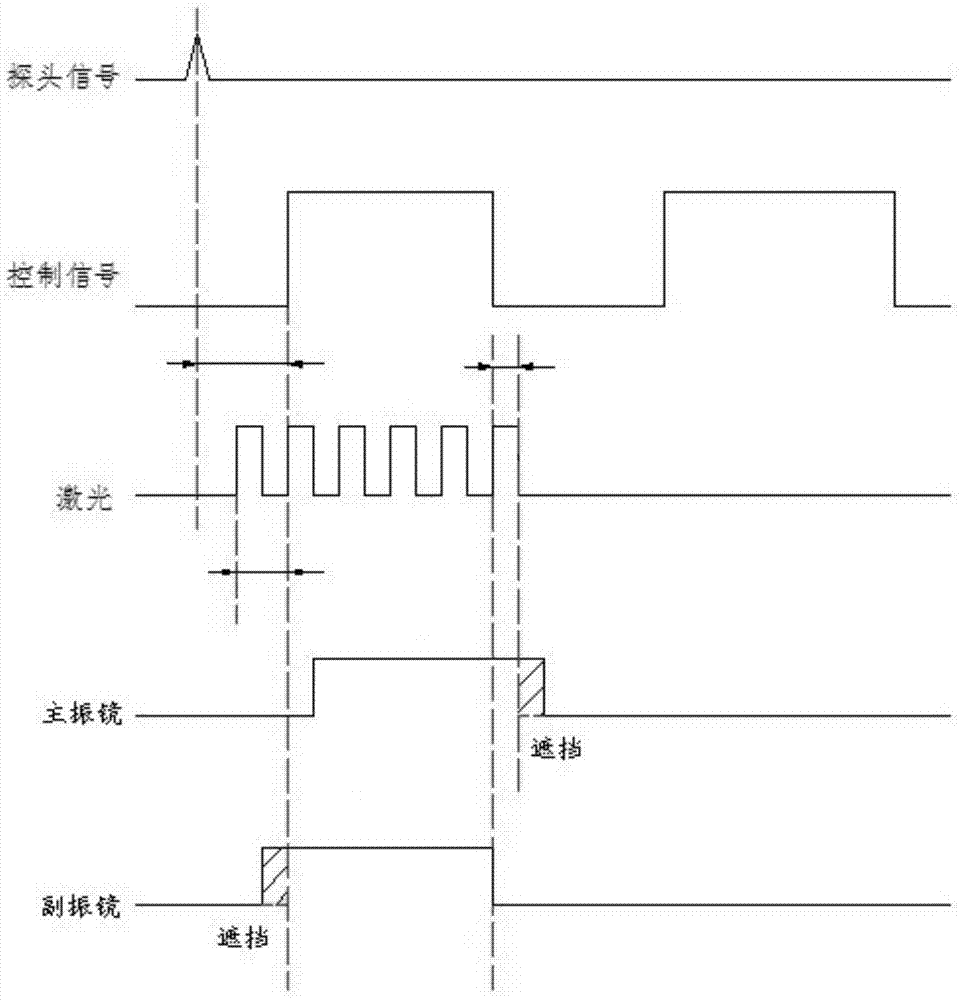

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

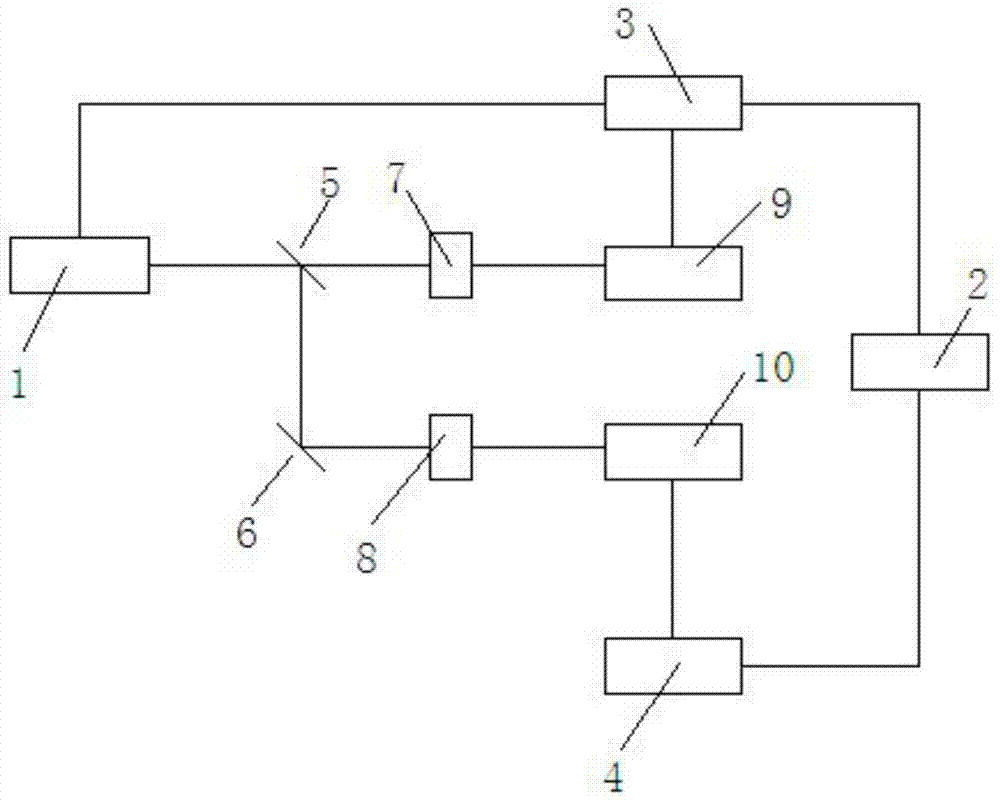

[0015] Such as figure 1 As shown, the double optical path laser on-the-fly coding system of the present invention includes a laser 1, a beam splitter, a light gate, a vibrating mirror and a control system, and also includes a computer 2, and the beam splitter includes a main beam splitter 5 and a secondary beam splitter 6, all The optical shutter includes a main optical shutter 7 and an auxiliary optical shutter 8, the vibrating mirror includes a main vibrating mirror 9 and an auxiliary vibrating mirror 10, the control system includes a main control system 3 and an auxiliary control system 4, and the main control system 3 and the secondary control system 4 are respectively connected with two output ports of the computer 2, the first signal output end of the main control system 3 is connected with the laser 1 control end, and the second signal ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com