Circulating water tank used for washing logging rock debris

A technology of circulating water tanks and cuttings, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as difficult to meet the technical requirements of mud logging site, waste of water resources, etc. , achieve the effect of breaking through the structure and working principle, improving the utilization rate, and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

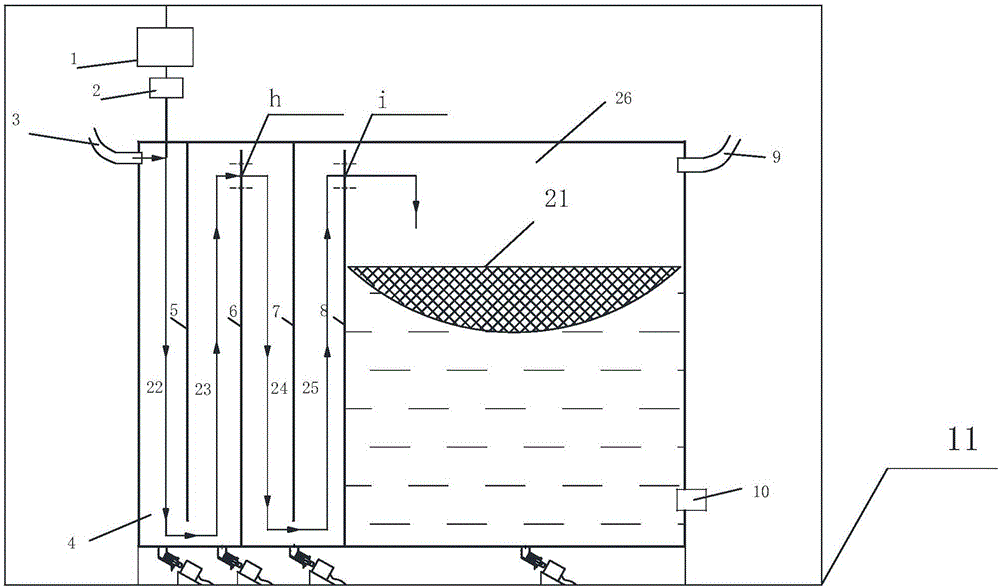

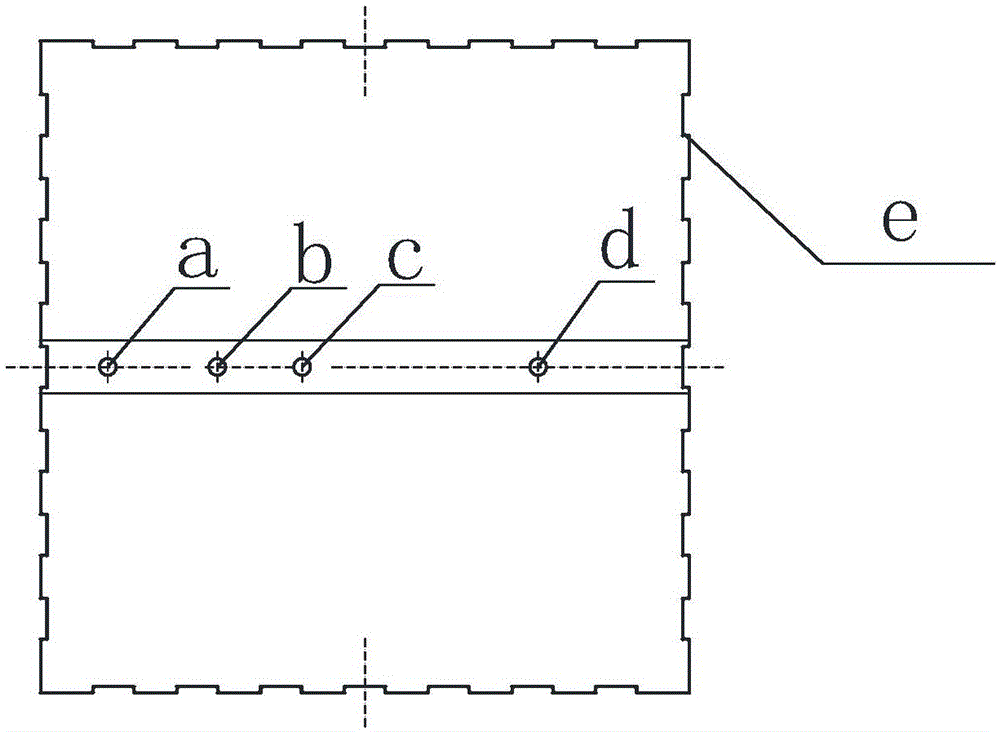

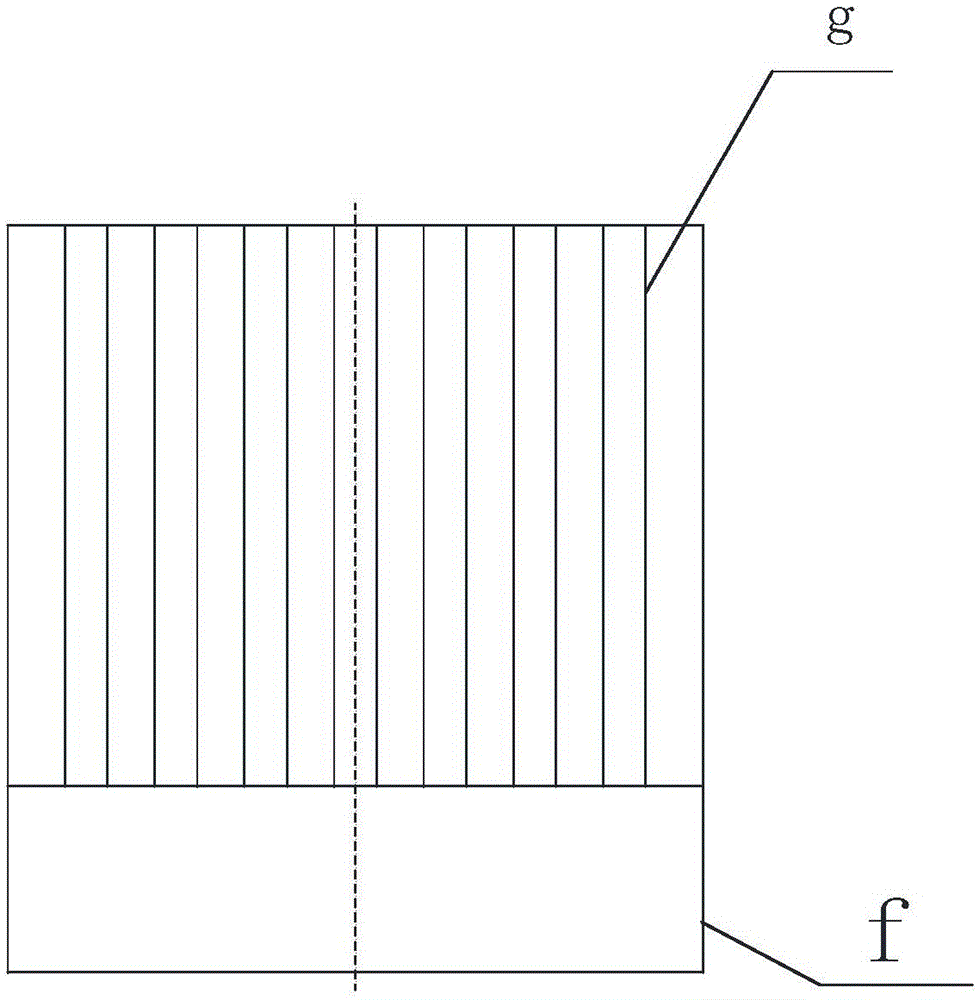

[0029] like figure 1 As shown, a circulating water tank for mud logging cuttings cleaning includes a sewage chamber 4 and a clean water chamber 26. Sewage chamber 4 has four vertical partitions built in, which are partition one 5, partition two 6, partition three 7 and partition four 8, partition one 5 and partition three 7 The bottom of the partition plate 2 6 and the top of the partition plate 4 8 are suspended in the air, the channel formed by the top suspension is much smaller than the channel formed by the bottom suspension, and the upper part of the partition plate 2 6 is provided with a water hole 1h, divided The upper part of the partition 4 8 has a water hole 2 i, the sewage inlet 3 is located on the upper part of the sewage chamber 4, and the sewage inlet 3 is provided with a flocculant, demulsifier automatic adding device 1 and a reg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com