Method for preparing biodegradable aliphatic thermoplastic poly(ester urethane) and its elastomer by non-isocyanate method

A non-isocyanate method and biodegradable technology, which is applied in the field of non-isocyanate method to prepare biodegradable aliphatic thermoplastic poly(ester urethane) and its elastomers, can solve the problem that it is not suitable for TPU materials, and it is difficult to meet the requirements of plastics or elastomers. , low glass transition temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

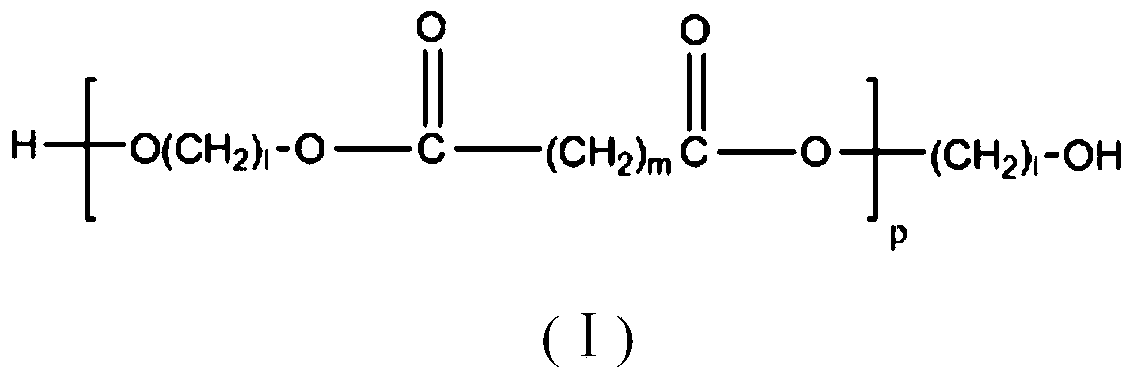

[0026] 1) Preparation of hydroxyl-terminated polybutylene adipate oligomer (PrePBA): 36.38 parts by weight of adipic acid, 33.75 parts of 1,4-butanediol, 0.14 parts of phosphorous acid, 0.14 parts of After stannous chloride was reacted at 150°C for 1 hour, the temperature was gradually raised to 200°C. When the amount of water evaporated reached the theoretical value, the water pump was used to gradually reduce the pressure for 4 hours, and then the oil pump was used to reduce the pressure to 1-5mmHg for 3 hours. A polybutylene adipate prepolymer PrePBA having an acid value of 1.91 mgKOH / g and a hydroxyl value of 68.54 mgKOH / g was obtained.

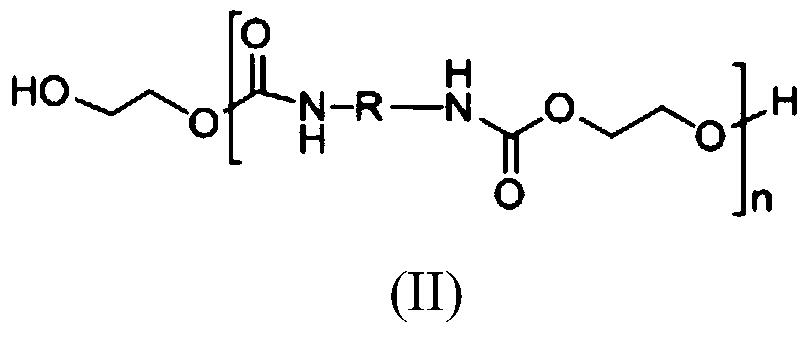

[0027] 2) Synthesis of diurethane diol prepolymer: Weigh 20 parts of hexamethylene diurethane diol monomer and 0.04 part of stannous chloride in parts by weight, melt and polycondense under reduced pressure with a water pump at 170°C for 1 hour, and then use The oil pump was decompressed to a vacuum degree of 1 to 5 mmHg and reacted for 1...

Embodiment 2

[0030] 1) Synthesis of hexamethylenediurethanediol prepolymer: Weigh 20 parts of hexamethylenediurethanediol monomer and 0.04 part of stannous chloride in parts by weight, react under reduced pressure with a water pump at 170°C for 1 hour, and then use The oil pump was decompressed to a vacuum degree of 1 to 5 mmHg and reacted for 2.3 hours to obtain a hexamethylene diurethane diol prepolymer with a hydroxyl value of 55.60 mgKOH / g.

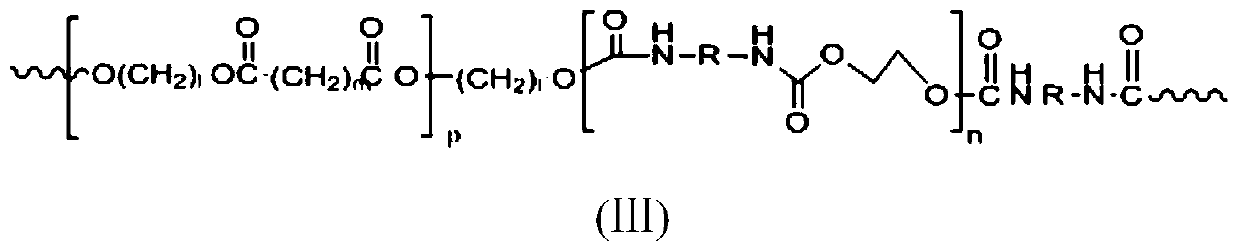

[0031] 2) Take by weight 6.33 parts and 0.012 parts of stannous chloride of 6.33 parts of hexamethylenediurethane diol prepolymer prepared in 5 parts of PrePBA prepared in embodiment 1 step 1), embodiment 2 step 1), in At 170°C, use an oil pump to depressurize to 1-5mmHg and react until the viscosity of the polymer no longer increases. The number average molecular weight of the obtained poly(ester urethane) is 17900, and the melting point is T m It is 94.21°C, its tensile strength is 14.52MPa, its elongation at break is 629.35%, its rebound rate a...

Embodiment 3

[0033] 1) Synthesis of diurethane diol prepolymer: Weigh 20 parts of hexamethylene diurethane diol monomer and 0.04 part of stannous chloride in parts by weight, react under reduced pressure with a water pump at 170°C for 1 hour, and then use an oil pump to Reduce the pressure to a vacuum degree of 1-5 mmHg and react for 7.2 hours to obtain a hexamethylene diurethane diol prepolymer with a hydroxyl value of 37.69 mgKOH / g.

[0034] 2) Take by weight 5 parts of PrePBA prepared in embodiment 1 step 1) and 9.34 parts of hexamethylene diurethane diol prepolymer prepared in embodiment 3 step 1), 0.012 part of stannous chloride at 170 ℃ with an oil pump to depressurize to 1-5mmHg and react until the viscosity of the polymer no longer increases. The number-average molecular weight of the obtained poly(ester urethane) is 17300, and the melting point is T mIt is 113.23°C. Its tensile strength is 18.81MPa, its elongation at break is 450.04%, its rebound rate is 67.12% when stretched at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com