A preparation method of carbon nanotube yarn composite cobaltate metal oxide nanowire supercapacitor

A supercapacitor, carbon nanotube technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor current collectors, etc., can solve the problems of large size, incompatible with the miniaturization and flexibility of integrated devices, and achieve high electrochemical performance , Excellent spinnability, high capacitance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

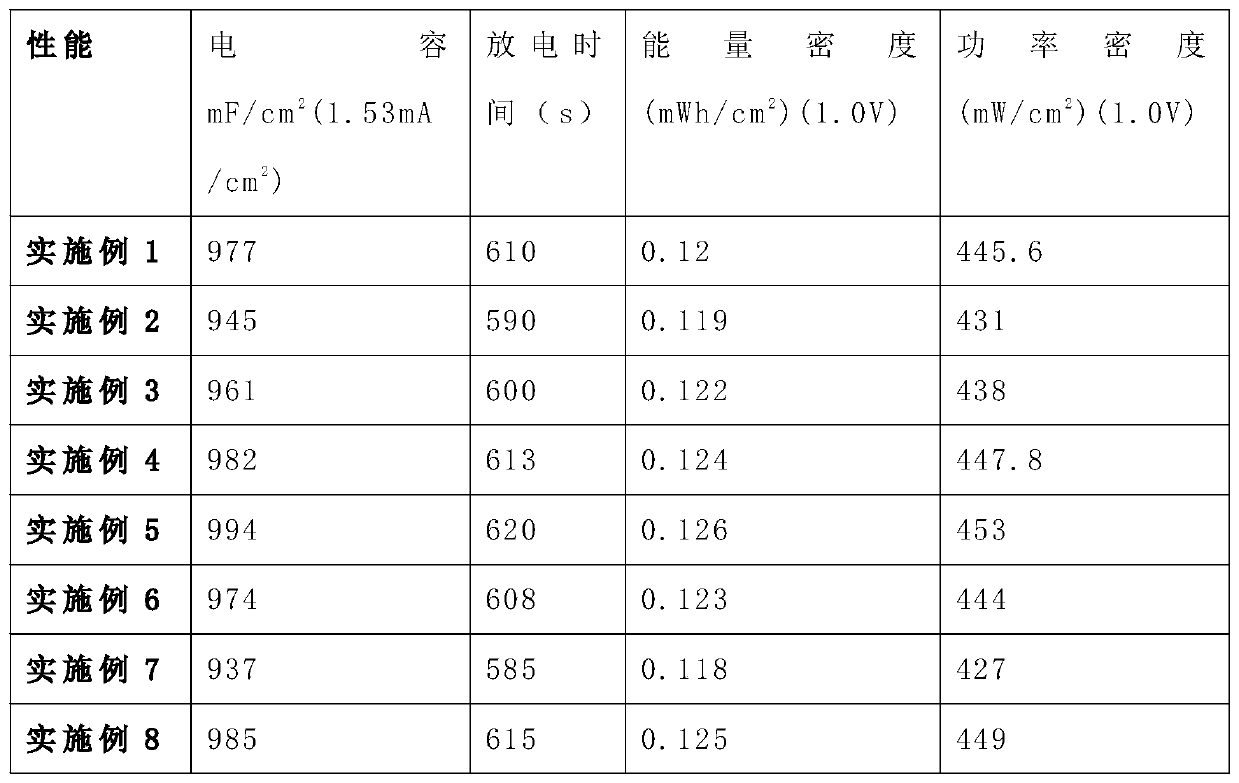

Examples

Embodiment 1

[0031] A carbon nanotube yarn composite cobaltate metal oxide nanowire supercapacitor, the preparation method of which is as follows:

[0032] A platinum wire with a diameter of 15 microns and a carbon nanotube yarn with a diameter of 20 microns are intertwined to form a double-ply yarn (referred to as Pt / CNT-1520); 1 mmol nickel chloride, 2 mmol cobalt chloride, 3 mmol urea, 6 mmol After mixing potassium fluoride and 30ml deionized water evenly, put a piece of Pt / CNT-1520 with a length of about 15 cm into the above mixed solution, and react in an autoclave at 90°C for 12 hours to form a surface containing nickel cobalt oxide nanoparticles. Then the composite yarn was taken out and washed three times with deionized water and ethanol respectively, and calcined in a muffle furnace at 350°C for 1.5 hours to obtain nickel cobaltate nanowires (diameter About 100nm) (marked as Pt / CNT / NiCo 2 o 4 -1520A); put two Pt / CNT / NiCo 2 o 4 -1520A yarn is immersed in polyvinyl alcohol-potas...

Embodiment 2

[0035] A carbon nanotube yarn composite cobaltate metal oxide nanowire supercapacitor, the preparation method of which is as follows:

[0036]A gold wire with a diameter of 12 microns and a carbon nanotube yarn with a diameter of 15 microns are intertwined to form a double-ply yarn (referred to as Au / CNT-1215); 1mmol zinc chloride, 2mmol cobalt chloride, 6mmol urea, 6mmol After mixing potassium fluoride and 40ml of deionized water evenly, put an Au / CNT-1215 yarn with a length of about 15 cm into the above mixed solution, and react in an autoclave at 100°C for 10 hours to form a surface containing cobalt acid Composite yarns of zinc nanowire precursors, then take out the composite yarns and wash them with deionized water and ethanol three times respectively, and calcinate them in a muffle furnace at 320°C for 1.5 hours to obtain zinc cobaltate nanowires on the surface of Au / CNT-1215 (about 90nm in diameter) (recorded as Au / CNT / ZnCo 2 o 4 -1215A); two Au / CNT / ZnCo 2 o 4 -1215...

Embodiment 3

[0039] A carbon nanotube yarn composite cobaltate metal oxide nanowire supercapacitor, the preparation method of which is as follows:

[0040] A silver wire with a diameter of 50 microns and a carbon nanotube yarn with a diameter of 20 microns are intertwined to form a double-ply yarn (referred to as Ag / CNT-5020); 1mmol copper chloride, 2mmol cobalt chloride, 9mmol urea, 6mmol After mixing potassium fluoride and 30ml of deionized water evenly, put a Ag / CNT-5020 yarn with a length of about 15 cm into the above mixed solution, and react in an autoclave at 110°C for 8 hours to form a surface containing cobalt acid Composite yarns of copper nanowire precursors, then take out the composite yarns and wash them with deionized water and ethanol three times respectively, and calcinate them in a muffle furnace at 300°C for 2 hours to obtain copper cobaltate nanowires on the surface of Ag / CNT-5020 (about 80nm in diameter) (denoted as Ag / CNT / CuCo 2 o 4 -5020A); two Ag / CNT / CuCo 2 o 4 -...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com