Multitrack even overlapping laser cladding repair method for unequal width damage parts

A technology of laser cladding and repairing method, applied in metal material coating process, coating and other directions, can solve the problem of uneven distribution of structure and properties, and achieve the effect of improving uneven distribution of structure and properties and avoiding uneven lap joint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and examples, but the present invention should not be limited to the examples.

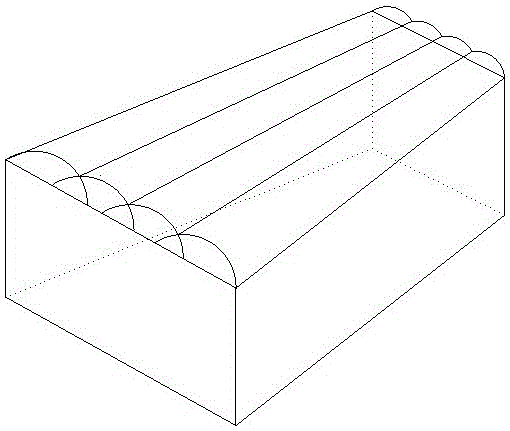

[0025] The cladding powder used in this example is Fe304 stainless steel, the base material of the sample is 316L stainless steel, its geometric size is 120 mm × 60 mm × 15 mm, and a line is cut in the middle part with a width of 20 mm at one end and a width of 20 mm at the other end. An isosceles trapezoidal groove with a width of 10 mm and a depth of 3 mm.

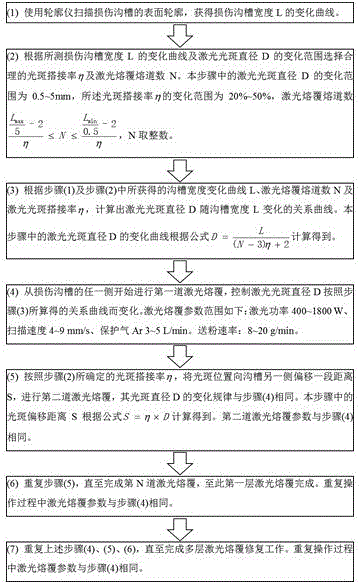

[0026] An example of using the above-mentioned processing method to repair the sample, the steps are:

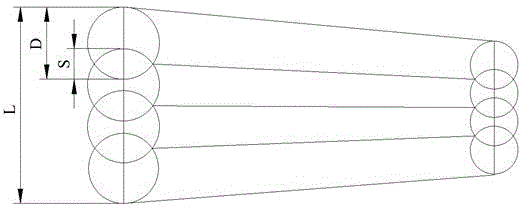

[0027] (1) Use a profiler to scan the surface profile of the damaged groove to obtain the change curve of the width L of the damaged groove, and obtain an isosceles trapezoidal change curve with an upper base width of 10 mm and a lower base width of 20 mm.

[0028] (2) According to the variation of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com