Length-adjustable yarn outgoing tube used for spinning

An adjustable and outlet pipe technology, applied in textiles and papermaking, etc., can solve the problems of not being able to meet the requirements of modern textiles, the length of pipes cannot be adjusted, and a single pipe, etc., and achieve the effect of good popularization and utilization value, simple structure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

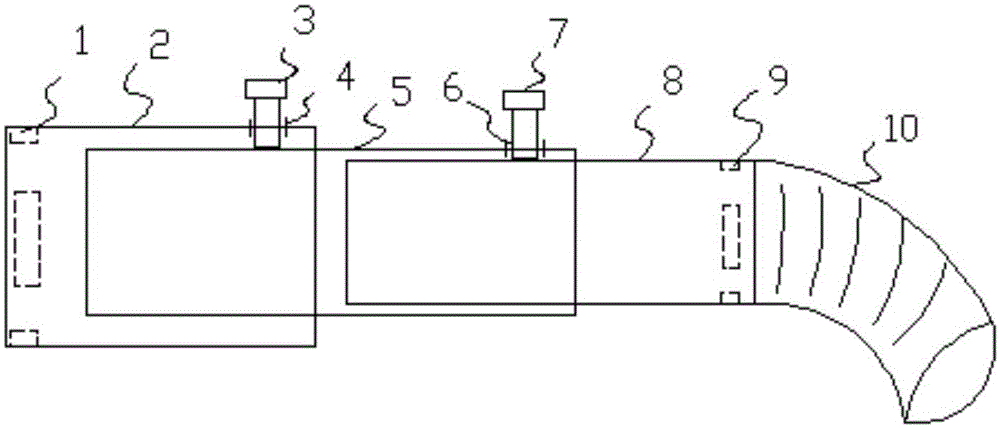

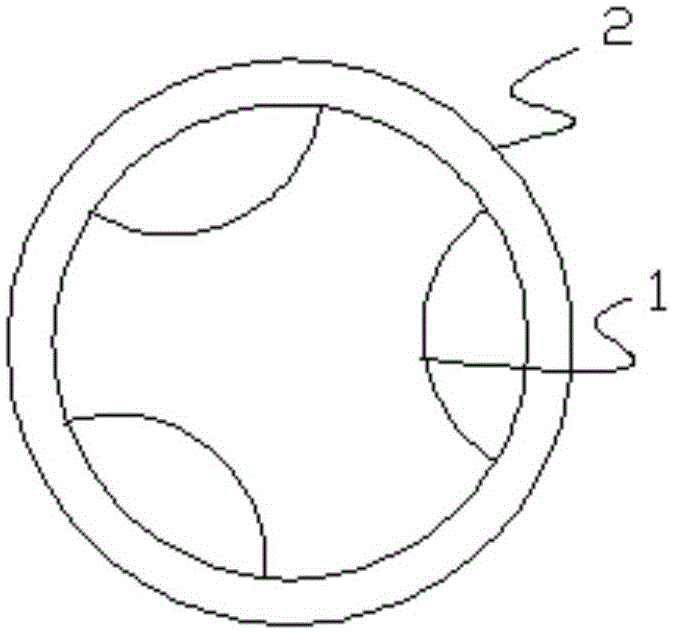

[0018] Such as figure 1 , figure 2 As shown, the length-adjustable textile outlet pipe includes a first sleeve 2 , a second sleeve 5 and a third sleeve 8 .

[0019] In the above embodiment, specifically, the first sleeve 2 is provided with a first screw hole 4, and the first screw hole 4 is provided with a first fastening bolt 3; the second sleeve 5 is provided with a There is a second screw hole 6, and a second fastening bolt 7 is arranged in the second screw hole 6; this design can be used to adjust the length of the outlet pipe.

[0020] In the above embodiment, specifically, the first sleeve 2 is provided with a number of first wire fixing clips 1, and the third sleeve 8 is provided with a number of second wire fixing clips 9, which are designed to Fixing the textile thread can play the role of lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com