Method for improving condensate oil recovery ratio through injecting water into fracture-cave type carbonate condensate gas reservoir

A technology for condensate gas reservoirs and carbonate rocks, which is applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc. It can solve problems such as difficulty in determining the connection relationship, large well spacing, and difficulty in carrying out cyclic gas injection, etc. To achieve the effect of enhanced recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

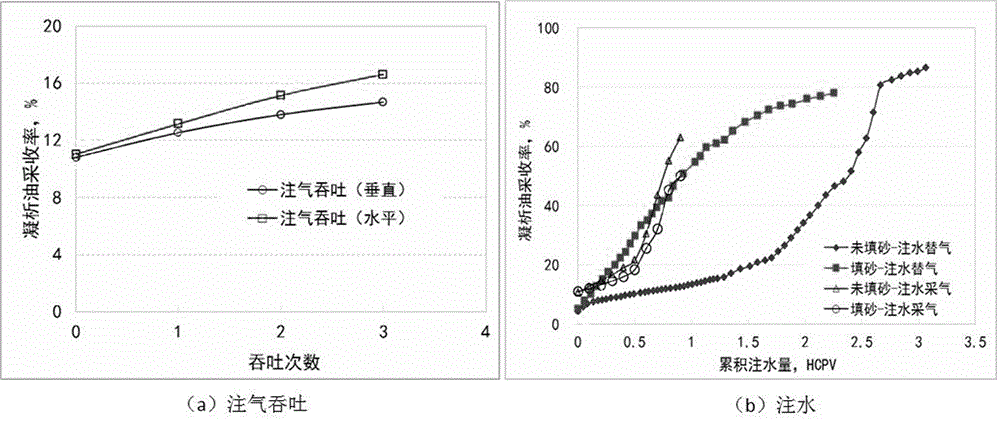

[0021] A method for enhancing the recovery of condensate oil by water injection in a fractured-cavity carbonate condensate gas reservoir, comprising the following steps:

[0022] 1) Reservoir type identification: The seismic profile shows “strong beading”, and during drilling, venting and leakage occur, and the oil pressure decreases exponentially during the test production period, showing the characteristics of relative constant volume, with a large decrease, and the well test explains the well-reservoir coefficient If the value is large and the kh value is large, it can be judged as a fracture-cavity reservoir;

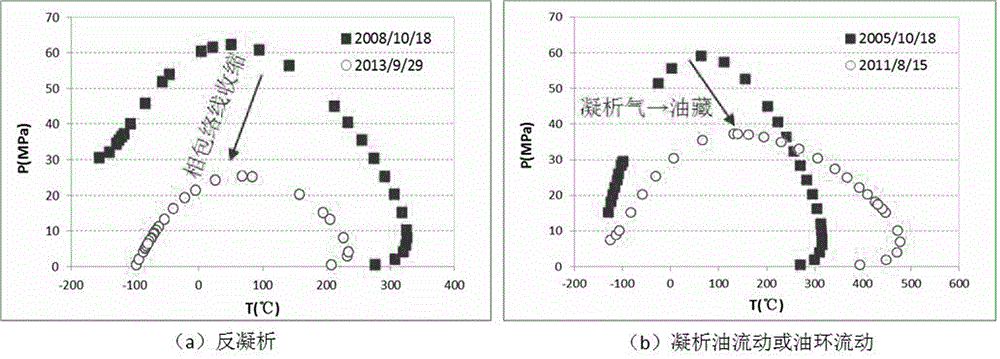

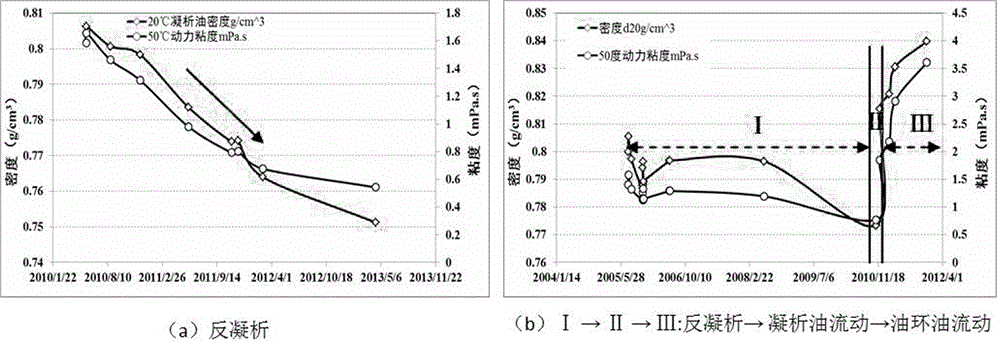

[0023] 2) Determination of reverse condensate and oil ring: According to PVT test, the production gas-oil ratio and the density change of produced condensate can determine the occurrence of reverse condensate; calculate the relevant parame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com