A Method of Measuring and Correcting the Rotation Angle of Cup and Bottle Cap Based on Machine Vision

A technology of rotation angle and machine vision, applied in the interpretation of photos, etc., can solve problems such as inconsistent rotation angles of bottles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0057] In this example, the camera adopts an area array gigabit network CCD camera (Baumer TXG12) with a resolution of 1080*960, the lens is a 6mm wide viewing angle Computar lens, and the light source is a dome diffuse reflection light source with a radius of 6cm (LTS-FM12030-WQ) ;

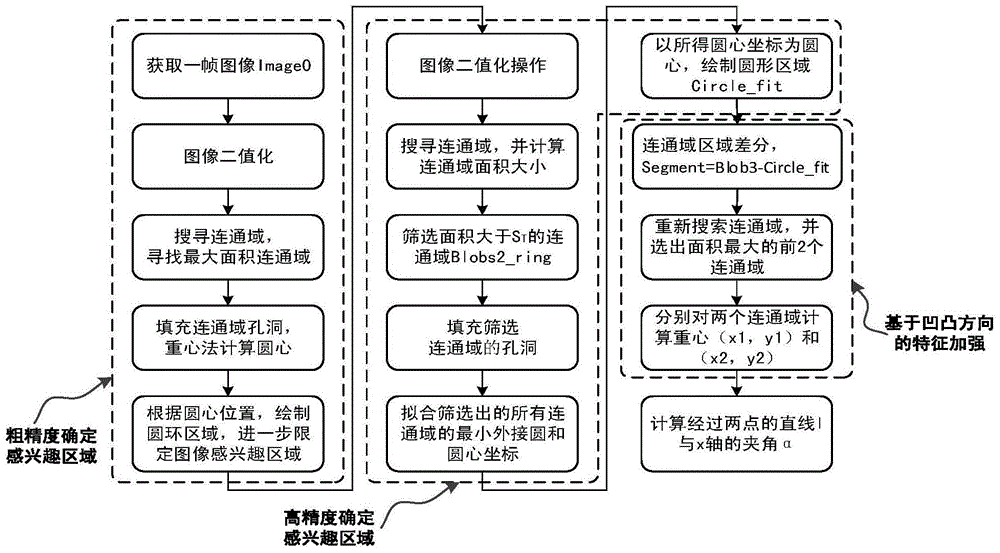

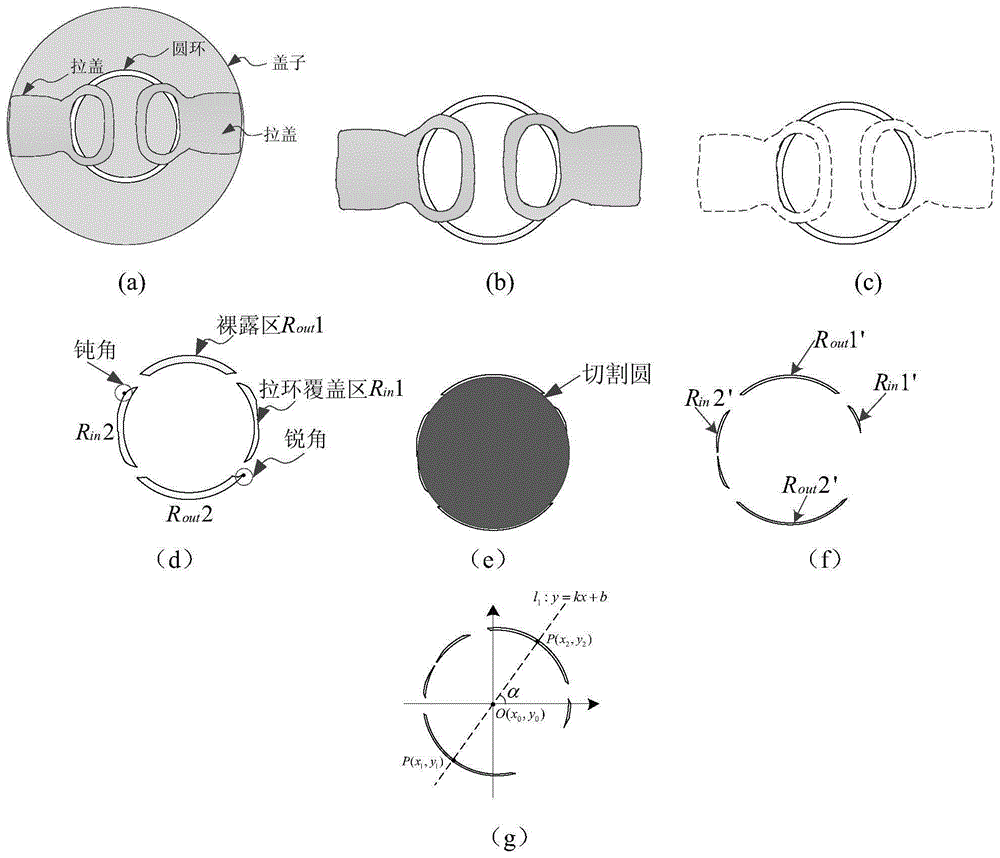

[0058] Such as figure 1 As shown, a machine vision-based method for measuring and correcting the rotation angle of the glass wine bottle cap includes the following steps:

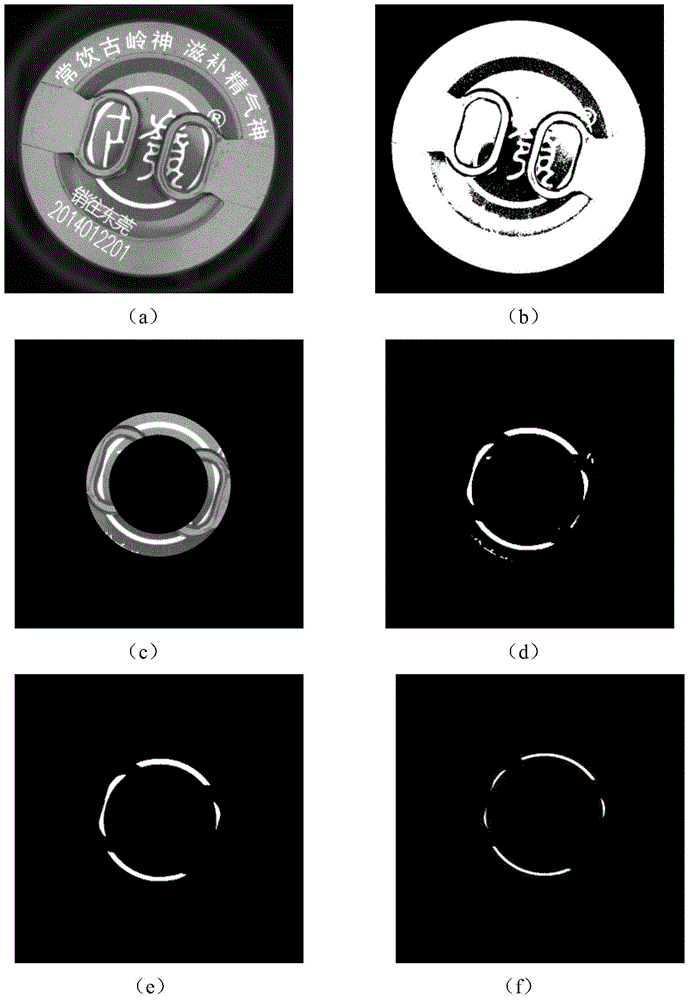

[0059] Step 1: Collect the image of the glass wine bottle cap located on the high-speed production line, denoted as Image0, such as image 3 as shown in (a);

[0060] Step 2: Binarize the bottle cap image Image0 to obtain a binary image Image1, such as image 3 as shown in (b);

[0061] Segment the cup and bottle cap from the background image, T1 is to set the binarization segmentation threshold, I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com