Pressure sensing method and sensor probe utilizing method

A sensor probe and sensing method technology, applied in the direction of fluid pressure measurement using optical methods, can solve the problems of cumbersome pressure measurement and calculation, poor sensor performance stability, low measurement accuracy, etc., and achieve adaptability and interchangeability progress. , strong practicability, calculated the effect of simple measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

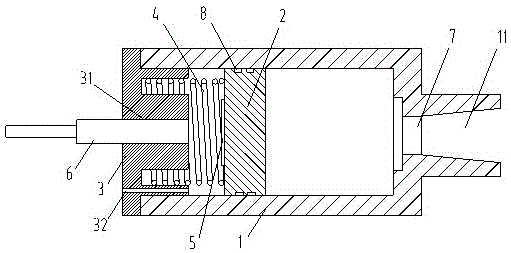

[0015] refer to figure 1 , this embodiment provides a differential pressure sensing method, which uses the pressure generated by the fluid to impact one side of a sliding piston 2, the piston 2 slides, and the other side of the piston 2 is provided with a spring 4 to limit the movement of the piston 2 At the same time, the other side of the piston 2 is also provided with a reflector 5, and irradiates the reflector 5 with the incident optical fiber in the fiber optic probe 6, and receives the reflected light with the receiving optical fiber in the fiber optic probe 6. After the piston 2 moves, the fiber optic probe When the distance between 6 and the mirror 5 changes, the reflected light changes accordingly, and the pressure caused by the detection fluid on the piston is judged by detecting the change of the output light intensity of the receiving optical fiber.

[0016] The sensor probe using the above-mentioned pressure sensing method includes a shell 1 with a cylindrical str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com