Method for describing creep curve of metal material

A technology of creep curves and metal materials, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., to achieve the effect of simple structure, high precision and outstanding physical meaning

Active Publication Date: 2015-10-28

SHENYANG POLYTECHNIC UNIV

View PDF11 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0017] The present invention aims at the problem that there is no simple and effective method for describing the creep curve of metal materials at present. Based on the creep mechanism of metal materials and combined with existing models, a new creep model is established.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

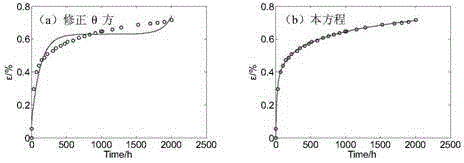

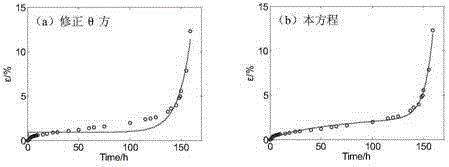

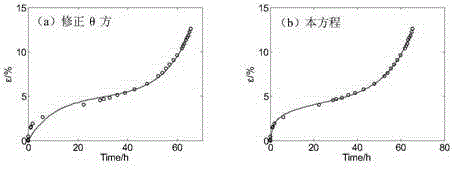

The method provides a method for describing the creep curve of a metal material, which comprises the steps of establishing a creep model, testing the creep curve of the metal material in the constant-temperature and constant-stress condition, fitting the creep data of the creep model, and determining the parameters of the creep model to obtain a creep equation. The data regression of the creep data is conducted according to the creep equation, so that a fitted creep curve for describing the creep process can be obtained. The model is simple in structure and outstanding in physical meaning. The model can concisely express the creep curves of various metal materials in the constant-temperature and constant-stress condition. A creep rate and a theta correction equation, calculated through the above model, are higher in accuracy. The creep curve is described by the creep equation, so that the creep properties of metal materials can be understood more deeply. The creep process is quantized and the variation trend of the creep curve can be predicted. Therefore, the method provides a more efficient technical support for the development of materials and the design and the usage of products.

Description

technical field [0001] The invention belongs to the research field of high-temperature mechanical properties of metal materials, and relates to a method for describing creep curves of metal materials. Background technique [0002] The study of creep performance is very important for the design and use of heat-resistant products, especially for key heating components such as thermoelectric, nuclear power units and aero-engines, various high-temperature and high-pressure containers, boilers and thermal pipelines. Creep performance not only involves To the use effect of the product, it also involves major safety issues. The indicators of creep resistance mainly include: steady-state creep rate, time to reach a certain deformation, creep life and elongation at break, all of which can be obtained by measuring creep curves. However, it is obviously unrealistic to determine the creep curve under arbitrary conditions. In fact, the experiments we have done are very limited. Therefor...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/18

Inventor 尚丽娟鲍识同

Owner SHENYANG POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com