Nuclear fuel subassembly video detection method and detection device

A nuclear fuel assembly and video detection technology, applied in the field of nuclear power generation, can solve problems such as poor detection accuracy and misjudgment, and achieve the effect of reducing errors and high judgment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

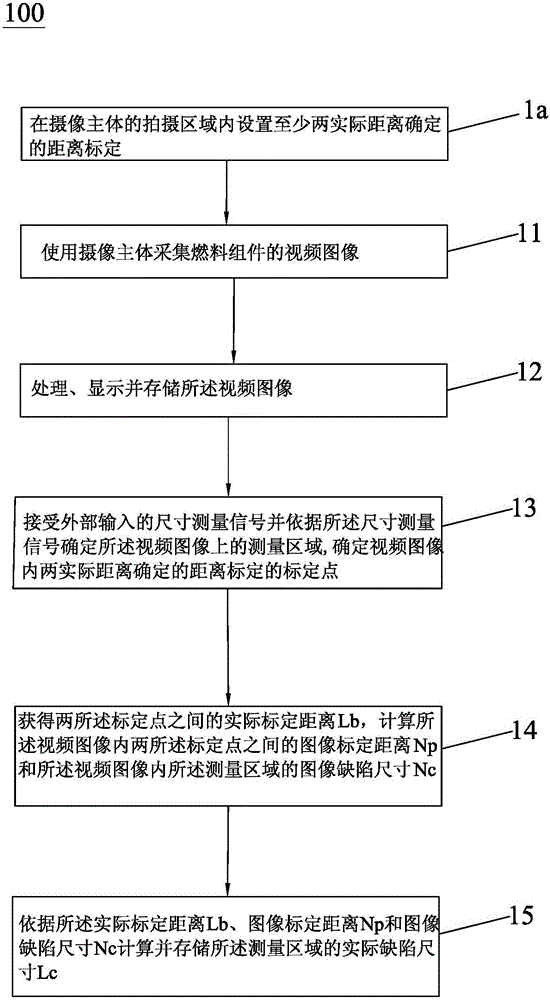

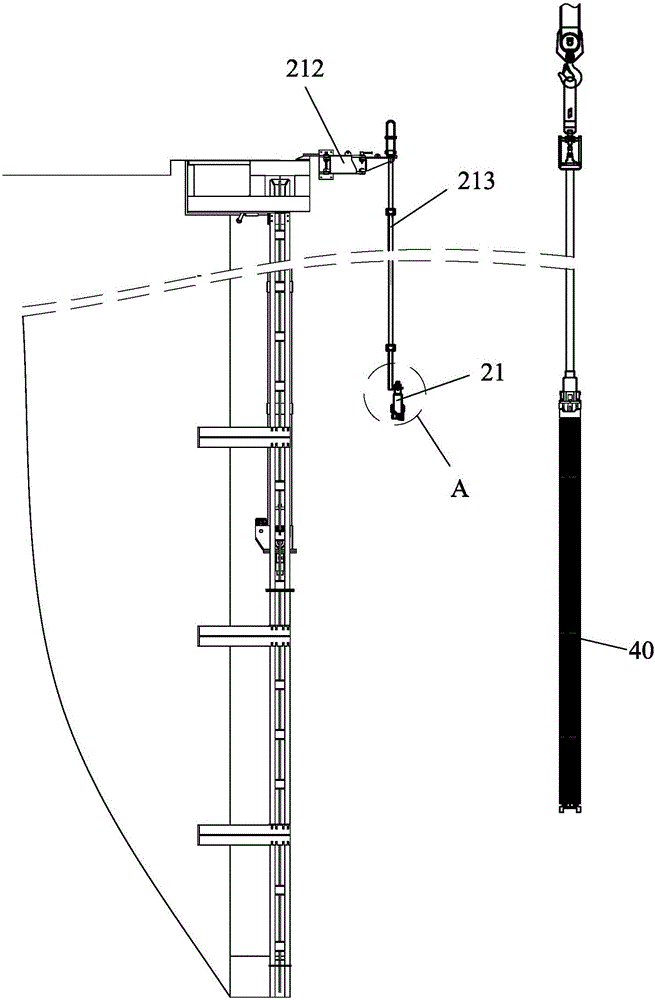

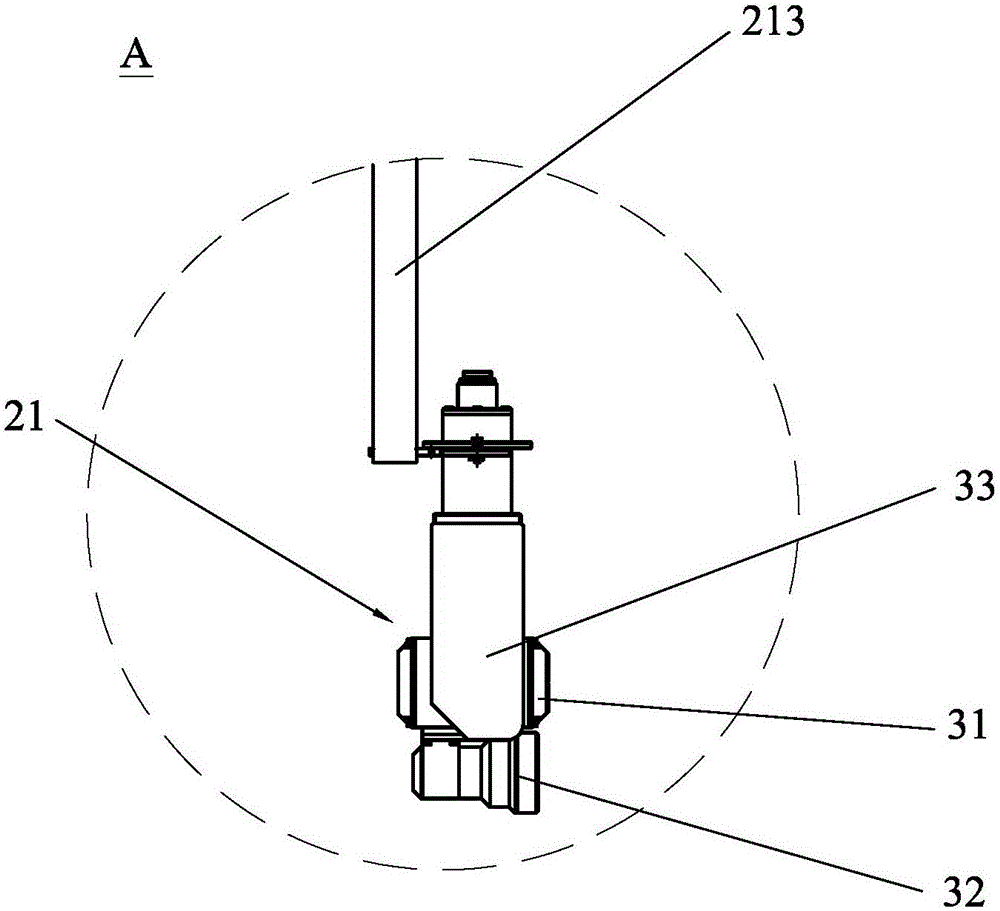

[0034] refer to Figure 2 to Figure 6, the present invention discloses a nuclear fuel assembly video detection device 200, including a camera body 21, a distance calibration device, a controller 22 and a control panel 23, refer to Figure 2 to Figure 5 , the camera subject 21 includes a camera 31 and a lighting lamp 32, and the camera subject 21 extends into the spent fuel pool and collects video images of nuclear fuel assemblies 40; the distance calibration device is set in the shooting area of the camera Distance calibration for at least two actual distance determinations. refer to Figure 6 , the controller 22 includes a control unit 221, an image processing unit 222 and a size calculation unit 223, the control unit 221 controls the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com