Automatic electric pole climbing operating platform

An automatic climbing and working platform technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of not being able to rotate 360° horizontally, not being able to carry operators, not being able to cross the cross arm, etc., to improve work efficiency and reduce labor intensity and the risk of accidents, the effect of unlimited scope of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

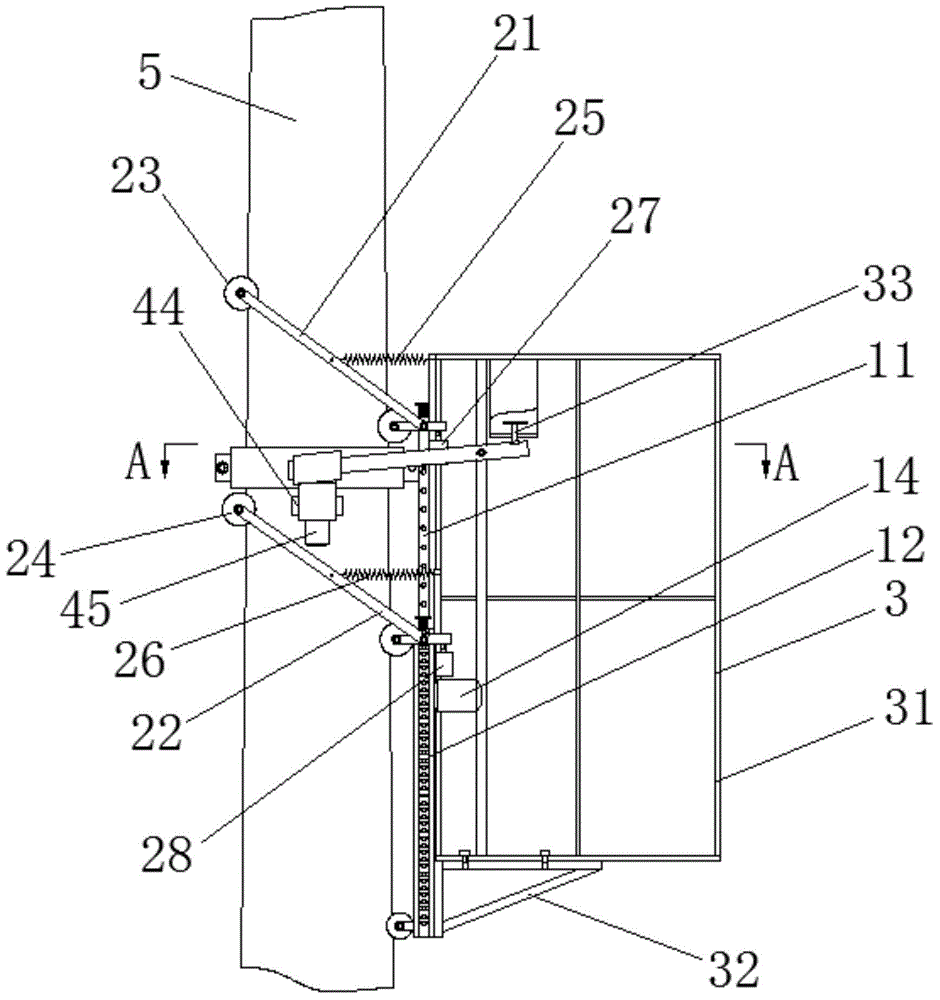

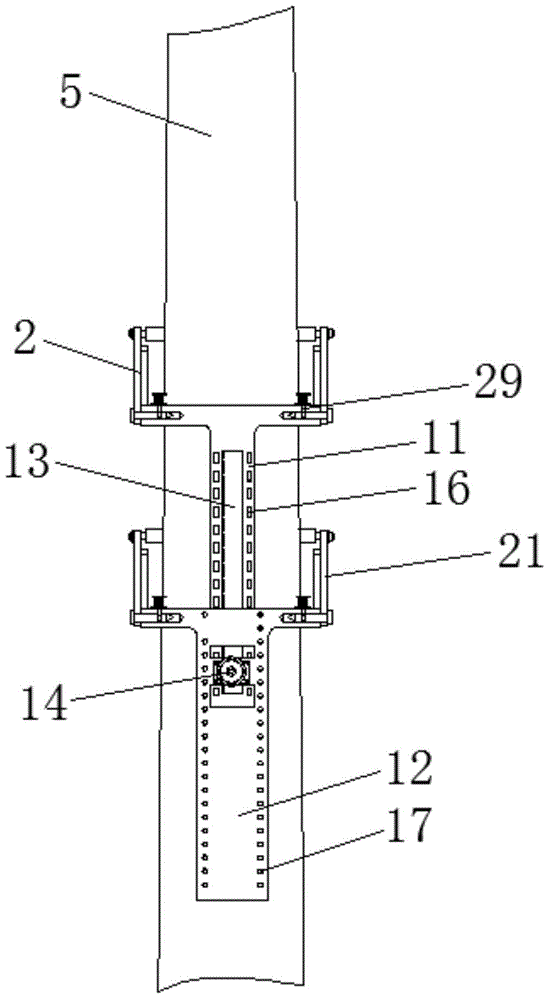

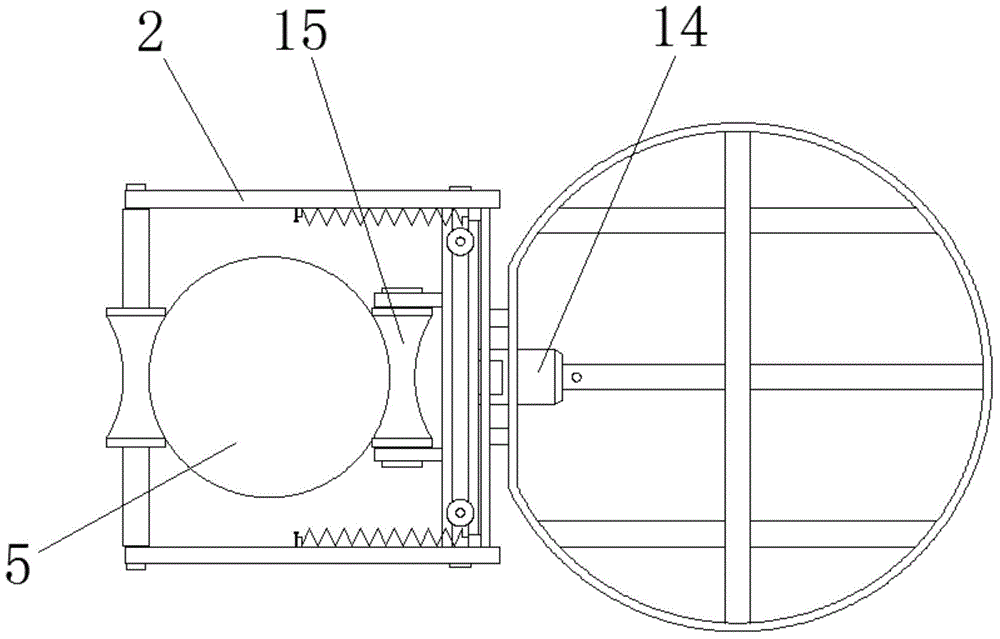

[0040] See Figure 1 to Figure 7 , The automatic pole climbing work platform of this embodiment includes a rack and pinion sliding climbing mechanism 1, a buckle locking mechanism 2, a working platform 3 and a hoop rotation mechanism 4.

[0041]The rack and pinion sliding climbing mechanism 1 includes an inner sliding arm 11 , an outer sliding sleeve 12 , a driving device, a climbing one-way guide wheel 15 , a first bearing 16 and a second bearing 17 . The inner sliding arm 11 extends into the outer sliding sleeve 12 from the top of the outer sliding sleeve 12 and is slidably connected with the outer sliding sleeve 12 . The driving device drives the inner sliding arm 11 to slide. The driving device includes a rack 13, a gear and a main motor 14. The rack 13 is fixed on the inner slide arm 11 . The gear is fixed on the output shaft of the main motor 14 and meshes with the rack 13 . The main motor 14 is fixed on the outer sliding sleeve 12 . The top of the inner sliding arm...

Embodiment 2

[0051] See Figure 8 to Figure 12 , this embodiment is basically the same as Embodiment 1, except that: the locking device 415 of the hoop 41 of the hoop rotation mechanism 4 includes a locking screw 4152 , a spring 4153 and a cover 4154 . The upper end surface of the outer ring 411 of the hoop 41 is provided with a through hole 4111 , and the upper edge of the through hole 4111 is provided with a deep groove 4112 and a shallow groove 4113 . The cover body 4154 is fixed above the through hole 4111 of the outer ring 411 . The shank of the locking screw 4152 passes through the through hole 4111 of the cover body 4154 and the outer ring 411 . The locking screw 4152 is provided with a limiting platform 41521 and a limiting protrusion 41522, the limiting platform 41521 is located inside the cover body 4154, and the limiting protrusion 41522 is located below the cover body 4154. The spring 4153 is disposed in the cover body 4154 and is located between the limiting platform 4152 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com