Power transmission busbar support

A busbar and support plate technology, which is applied in the direction of open busbar installation, etc., can solve problems such as difficulty in adapting to large-scale power transmission busbars and live equipment support, limited support force of insulators, and reduced support strength, so as to avoid electromagnetic effects and not easily Leakage conduction, the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

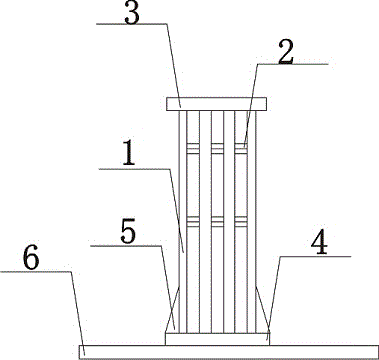

[0019] The present invention will now be described in further detail in conjunction with the accompanying drawings, which are simplified schematic diagrams, only schematically illustrating the basic structure of the present invention, and therefore only show the configurations related to the present invention.

[0020] Such as figure 1 The preferred embodiment of the power transmission busbar support of the present invention shown includes a busbar body 1, the busbar body 1 is composed of several wires, the top of the busbar body 1 is located on a connecting plate 3, and its bottom is located on a glass On the fiber insulation board 4, the glass fiber insulation board 4 and the connection board 3 are provided with contacts matching the busbar body 1, and the glass fiber insulation board 4 and the connection board 3 are both clipped on the busbar body 1, Wherein, a limiting plate 5 is installed between the glass fiber insulating plate 4 and the busbar body 1, the limiting plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com