Intergration of residue hydrocracking and solvent deasphalting

A deasphalting, hydroconversion technology, applied in the field of residual oil and other heavy hydrocarbon fraction hydrocracking, can solve the problems of limited to about 35% to 40%, limited conversion rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

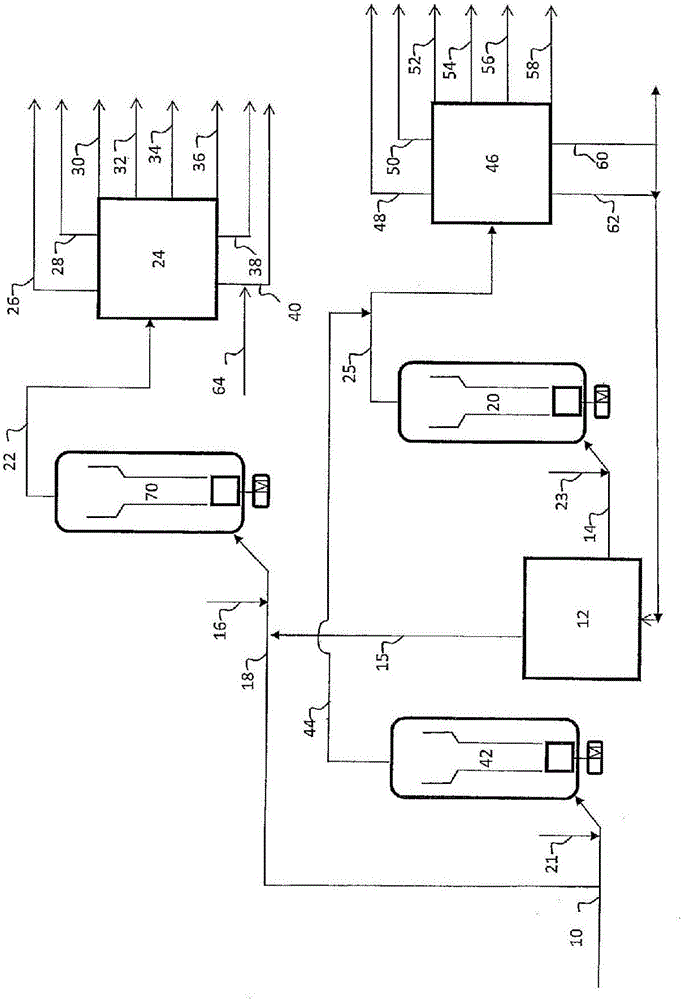

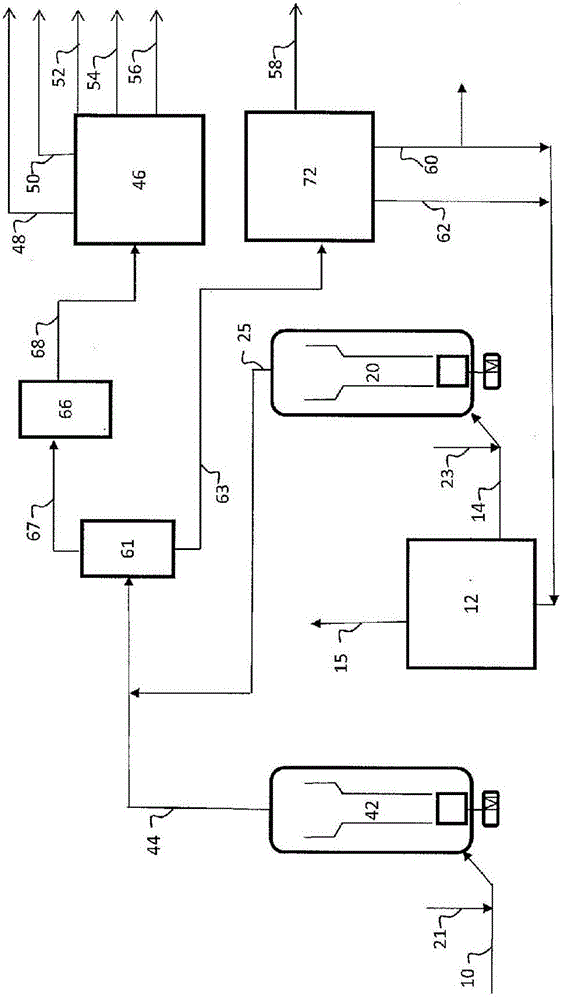

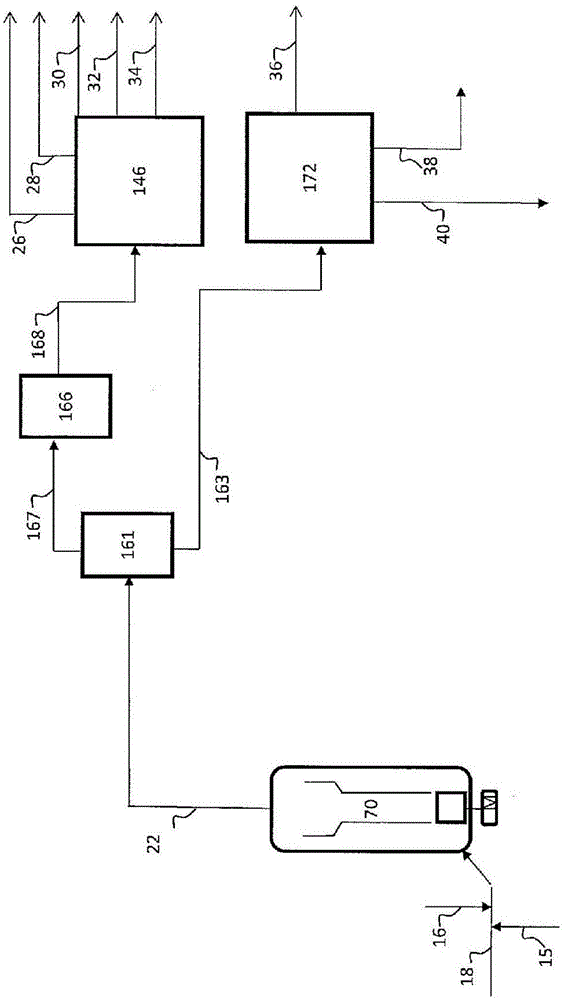

[0012] In one aspect, embodiments herein relate generally to hydroconversion processes, including processes to hydrocrack resid and other heavy hydrocarbon fractions. More specifically, embodiments disclosed herein relate to hydrocracking of resid hydrocarbon feedstocks, solvent deasphalting of unconverted resid hydrocarbon feedstocks, processing of the resulting hydrocracked hydrocarbon feedstock in a separate resid hydrocracking unit deasphalted oil, and the bitumen from the solvent deasphalted unit is processed in a separate residue hydrocracking unit.

[0013] The hydroconversion process disclosed herein can be used to react a residual hydrocarbon feedstock under conditions of elevated temperature and pressure in the presence of hydrogen and one or more hydroconversion catalysts to convert the feedstock to polluting Lower molecular weight products with reduced levels of compounds such as sulfur and / or nitrogen. Hydroconversion processes may include, for example, hydrogena...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com