Test socket with high density conduction section

A technology for testing sockets and conductive parts, which is applied in the direction of single semiconductor device testing, sensors, and measuring electricity. It can solve problems such as damage, conductivity-enhanced film deformation, and fracture, and achieve the effects of easy contact, improved conductivity, and durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Hereinafter, the test socket according to the embodiment of the present invention will be described in detail with the drawings.

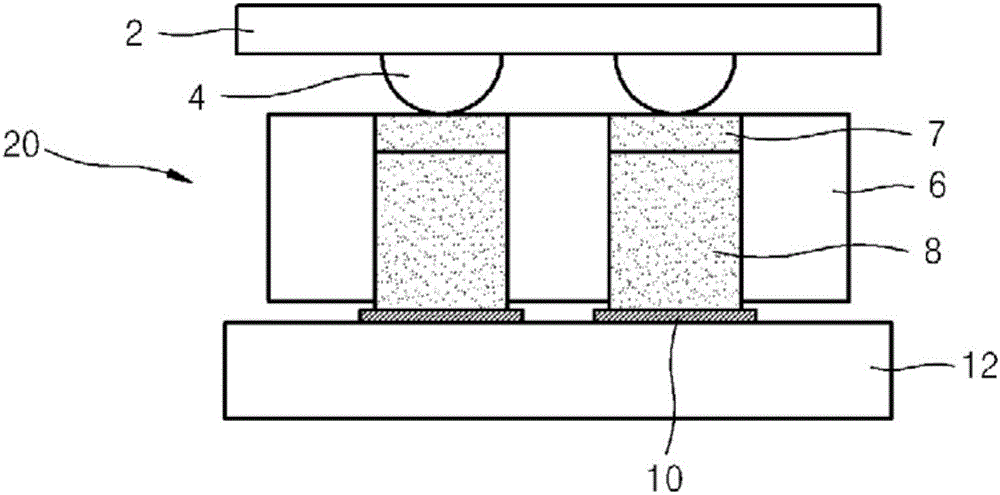

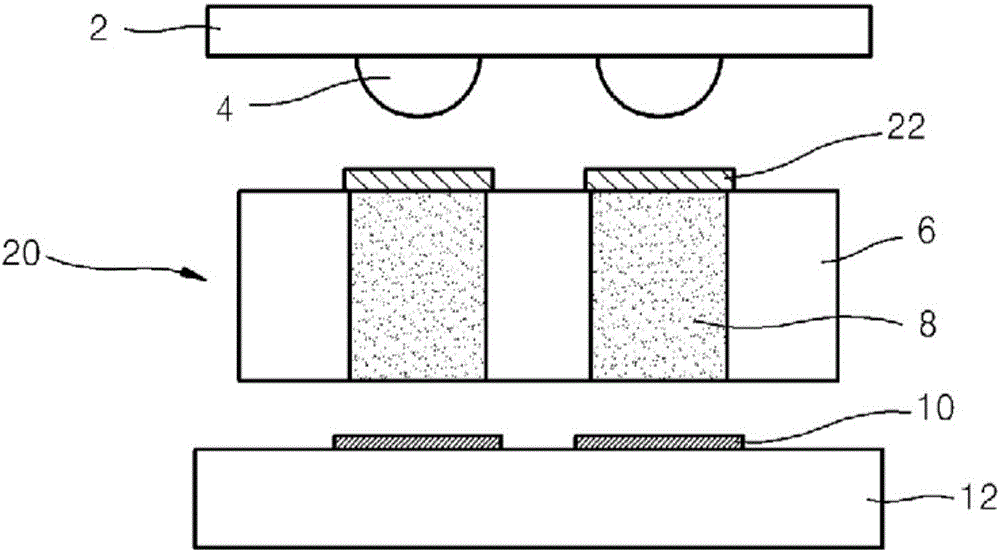

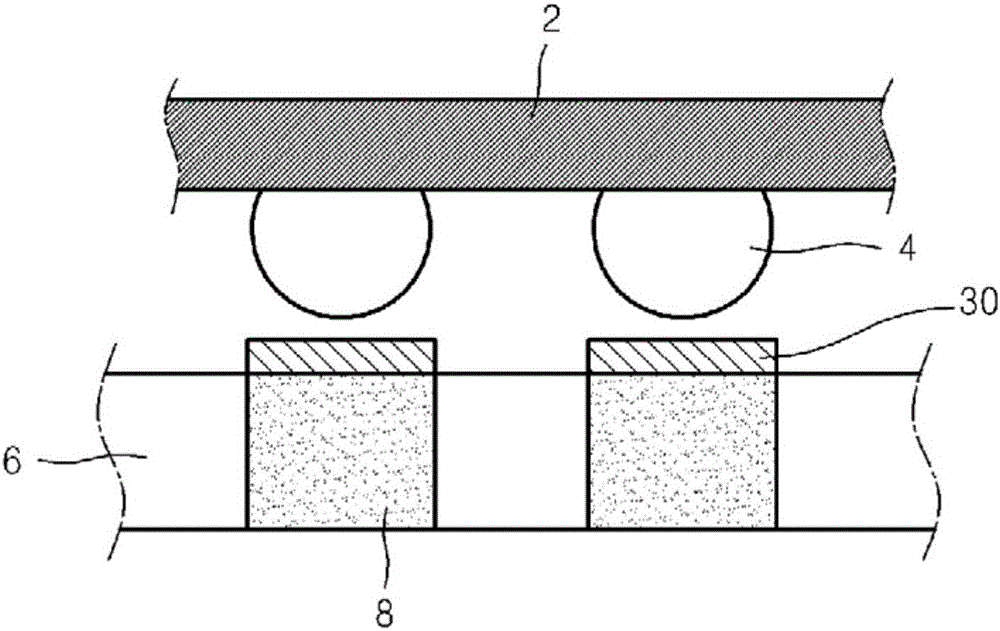

[0047] Figure 4 to Figure 6 A test socket (100) according to an embodiment of the present invention is explained. The test socket (100) is disposed between the device (800) to be tested and the test equipment (900) to electrically connect the terminals (801) of the device (800) to the pads (901) of the test equipment (900).

[0048] The test socket (100) includes an elastic conductive sheet (110), a supporting sheet (120), and a second conductive part (130).

[0049] The elastic conductive sheet (110) allows current to flow in its thickness direction, but does not allow current to flow in its surface direction perpendicular to the thickness direction. The elastic conductive foil (110) is elastically compressible to absorb any impact applied by the terminals (801) of the device (800). The elastic conductive sheet (110) includes a first co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com