Washing control method for transformer substation washing robot based on ultrasonic distance measurement

A control method and water flushing technology, applied in the field of robotics, can solve the problems of inaccurate control, inability to meet safety requirements, and low cleaning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] The present invention is described in detail below in conjunction with accompanying drawing:

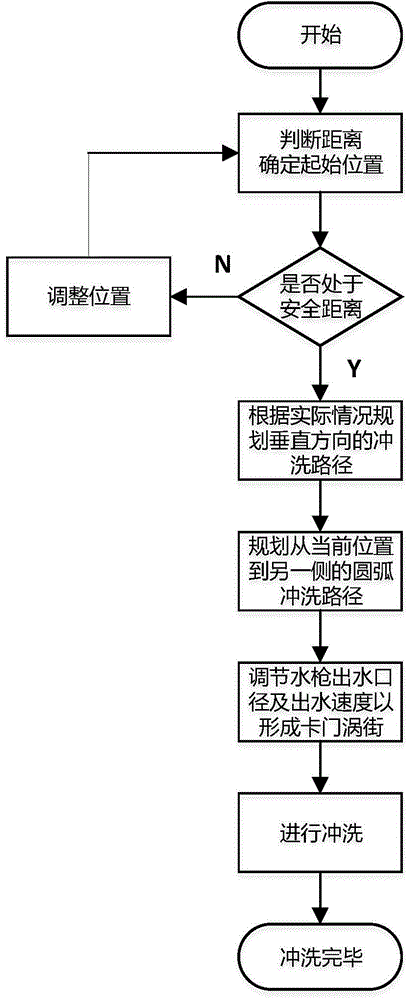

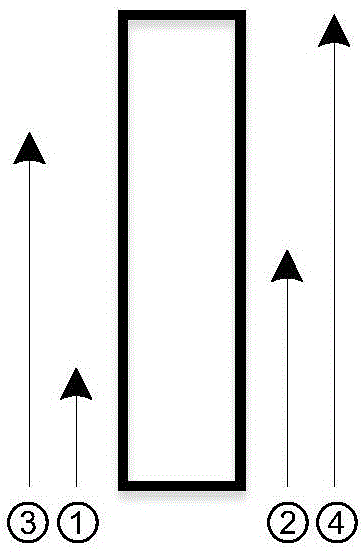

[0088] Such as Figure 1-3 As shown, the water flushing control method of the substation water flushing robot based on ultrasonic ranging includes the following steps:

[0089] Step 1: Establish the path planning model of the robot; the depth distance between the robot and the insulator can be obtained according to the ultrasonic range finder installed on the washing platform, and then image recognition is performed on the pictures obtained by the monitoring camera, so that the distance between the robot and the insulator can be obtained. At the same time, it can also judge the relative distance between the current robot and the insulator, ensure that the working distance is within the safe range, judge the position of the robot, and determine the initial state of the path planning;

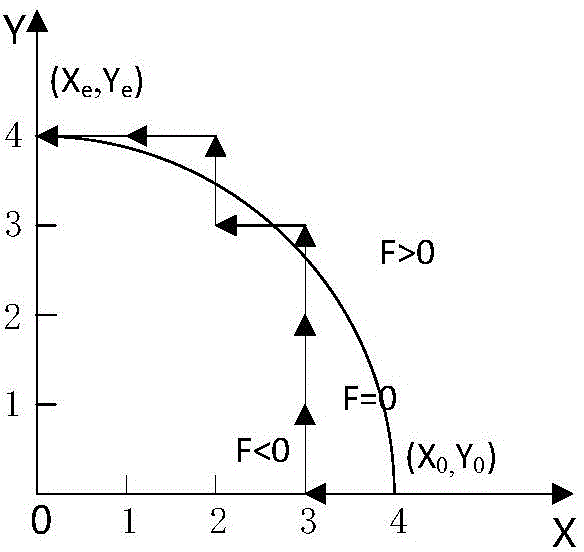

[0090] Step 2: Use the linear interpolation method to realize the automatic flushing of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com