Automatic panel feeding, cutting, arranging and stacking device

An automatic feeding and yarding technology, applied in the field of automatic production, can solve the problems of low production efficiency and high labor intensity, and achieve the effect of improving production efficiency, reducing hidden dangers, and ordering materials neatly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

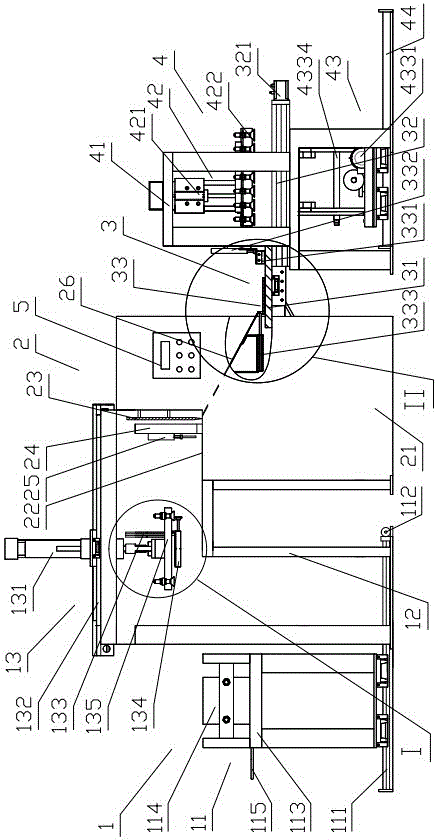

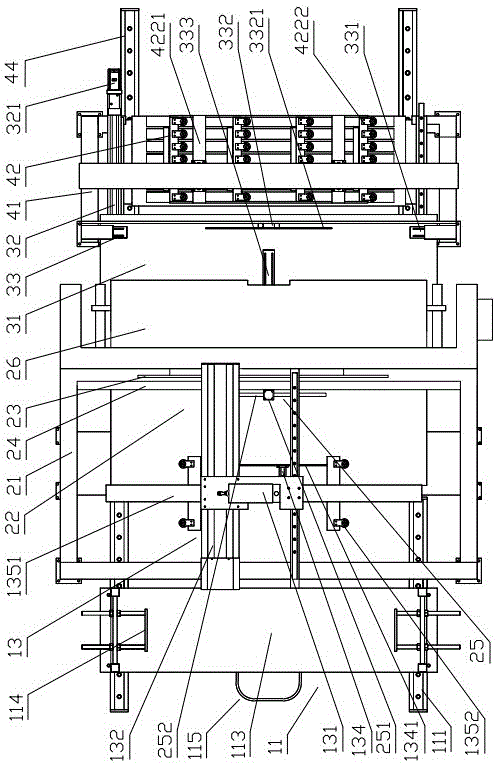

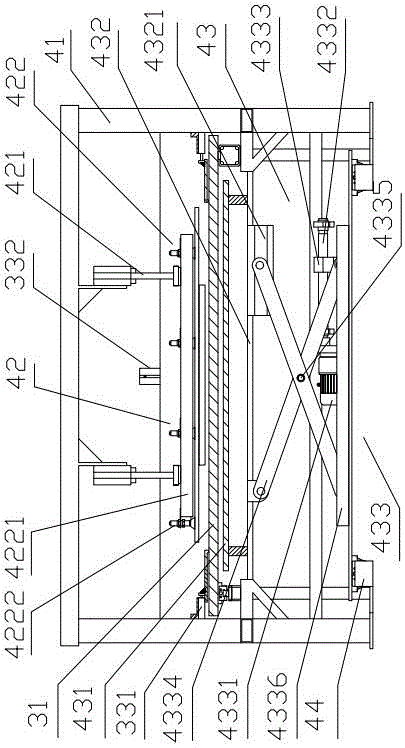

[0021] like figure 1 As shown, the equipment for automatically feeding, cutting and yarding plates includes a feeding device 1 for transporting plates into the cutting mechanism, a cutting device 2 for cutting plates, and a device for arranging the cut slats A discharge device 3, a code device 4 for stacking slats after the pre-arrangement is completed, and a PLC program controller 5. The feeding, cutting, discharging and coding actions completed by the present invention are all controlled by the PLC program controller 5 to complete.

[0022] like Figure 1~2 and Figure 4 As shown, the feeding device 1 includes a feeding trolley 11 , a feeding frame 12 and a feeding hanger 13 located above the feeding trolley 11 . The feeding trolley 11 includes a linear guide rail 111 installed on the ground surface, a limit switch 112 installed on one en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com