Assembling, disassembling and maintaining technological device for piston of piston type air compressor

A technology of process equipment and air compressors, which is applied in the direction of mechanical equipment, liquid variable capacity machines, hand-held tools, etc., can solve the problem of inability to realize the maintenance operation of the equipment body maintenance platform, the inability to effectively use labor force, and the inability to stand maintenance personnel at the same time and other issues to achieve the effect of improving labor productivity, increasing safety factor, and overcoming instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

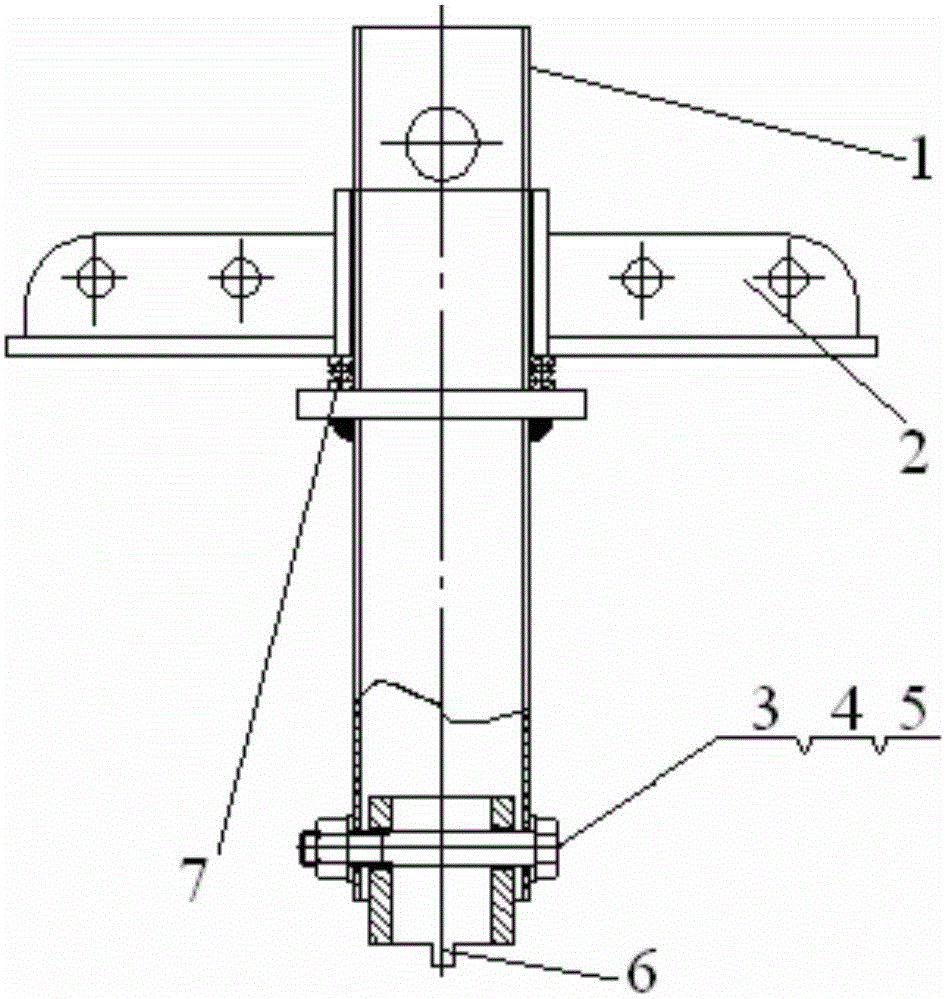

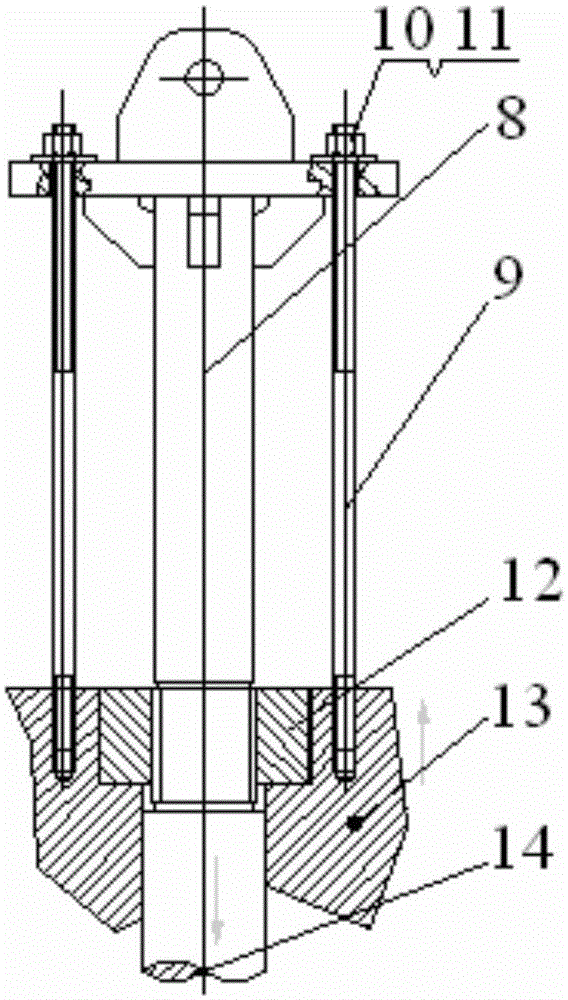

[0019] Such as figure 1 , figure 2 The structure of the present invention shown is a piston air compressor piston loading and unloading maintenance process equipment, and a special tool for piston gas compressor piston loading and unloading. It includes a nut sleeve 6; said piston 13 is connected with a piston rod 14.

[0020] In order to solve the problems existing in the prior art and overcome its defects, realize the invention purpose of making maintenance more convenient and reducing labor intensity, the technical scheme adopted by the present invention is:

[0021] Such as figure 1 , figure 2 As shown, the piston air com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com