Novel bead needle inserting machine

A technology of bead needle insertion and bead needles, which is applied in the field of new bead needle insertion machines, can solve the problems of affecting the insertion effect of bead needles and plastic discs, affecting the actual profit income of manufacturers, and rising labor costs, etc., to achieve Reduce labor costs and production costs, stable movement, fast and accurate packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

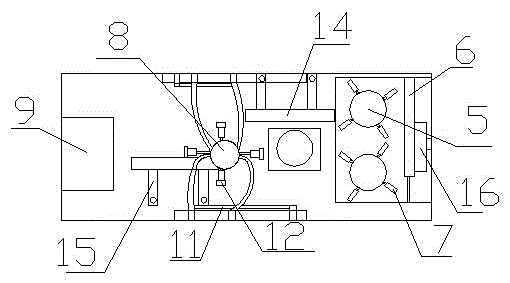

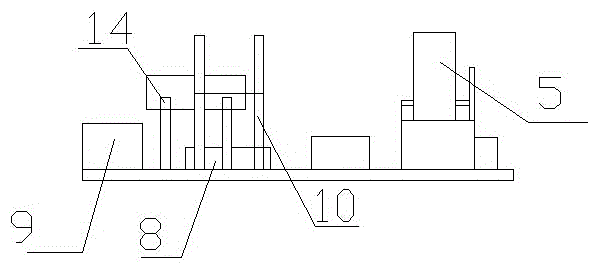

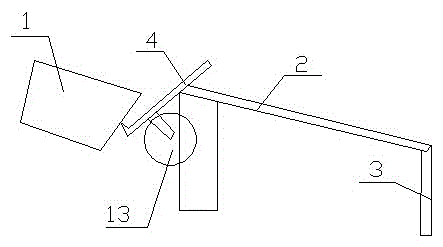

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] A new type of bead needle insertion machine, including a bead needle finishing mechanism and a disc needle insertion mechanism, the bead needle finishing mechanism includes a hopper 1 and a needle groove 2, the needle groove 2 is supported by a bracket 3, and the needle groove 2 is fixedly connected with a rack Hook 4, the disk needle insertion mechanism is composed of a disk distribution mechanism, a disk loading and unloading mechanism, a needle loading mechanism and a needle insertion mechanism. The disk distribution mechanism is composed of a plastic disk placement cylinder 5 and an air cylinder 6. The plastic circle Cylinders 7 are arranged around the disk placement cylinder 5. The disk loading and unloading mechanism is composed of a feeding electric slide cylinder 14, an unloading electric slide cylinder 15, and a material receiving box 9. There are upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com