Ink adsorption system and working principle thereof

An ink absorption and ink technology, which is applied in the field of ink absorption system and its working principle, can solve the problems of unsatisfactory ink absorption effect, difficulty in adjusting suction force, and prone to failure, and achieve the effects of low power, reduced noise, and reduced failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

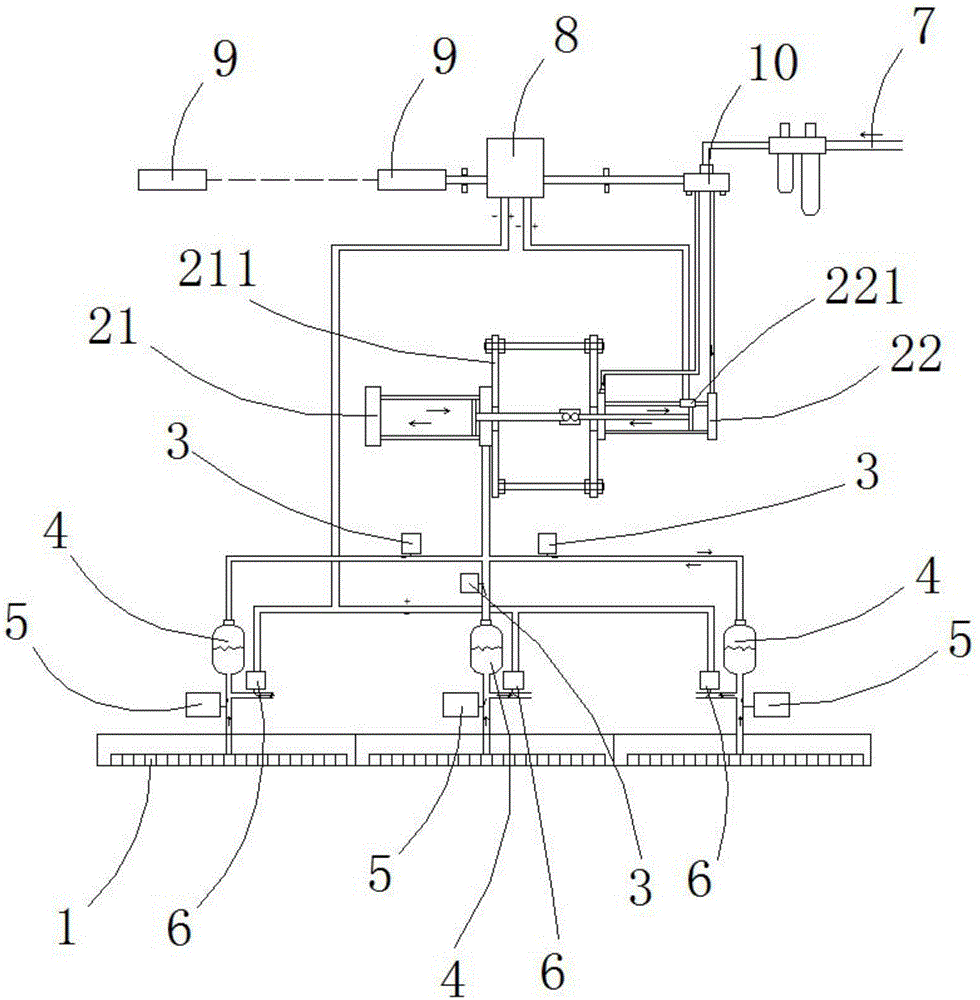

[0012] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] See attached figure 1 , the ink adsorption system of the present invention comprises ink cartridge 1, ink throttle valve 3, filter tank 4, one-way throttle valve 5, air inlet 7, PLC control module 8, enters brick to radio eye 9, one-way throttle valve 5 is installed between the ink cartridge 1 and the filter tank 4. There is a T-shaped ink discharge branch between the ink cartridge 1 and the filter tank 4. The upper part of the filter tank 4 is connected to one end of the ink throttle valve 3 through a gas pipe. The other end of flow valve 3 is connected with a positive and negative pressure cylinder 21, the connecting rod of the positive and negative pressure cylinder 21 is connected with the connecting rod of a push-pull cylinder 22, and the positive and negative pressure cylinder 21 and the push-pull cylinder 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com