A control method of rail vehicle grounding resistance and its grounding plate

A control method and grounding resistance technology, applied to locomotives, connecting contact materials, etc., can solve problems such as grounding resistance changes, grounding plate wear, and impact on train driving safety, so as to improve grounding reliability, stability and safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

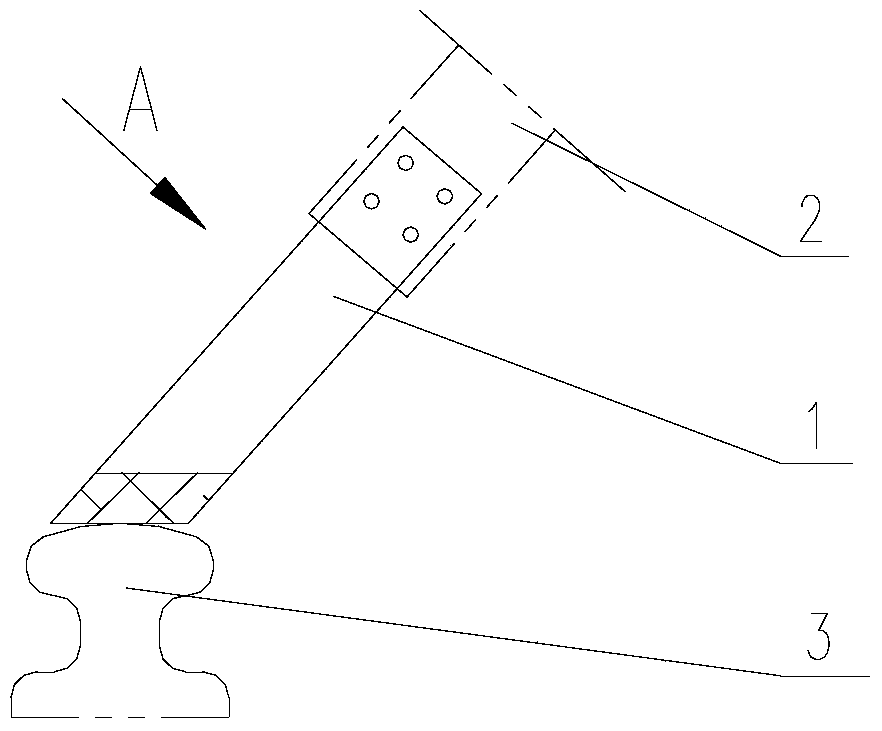

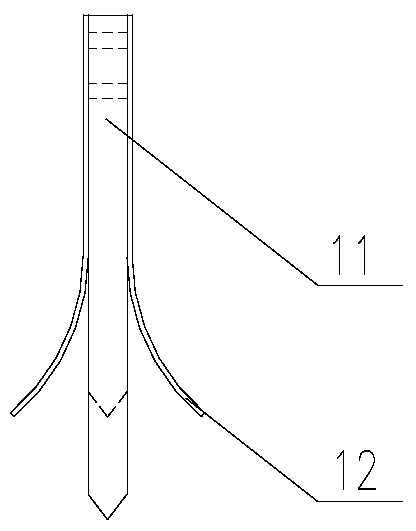

[0028] The core of the present invention is to provide a method for controlling the grounding resistance of a rail vehicle and its grounding plate, which can control the grounding resistance within a reasonable range, improve grounding reliability, and further improve driving safety.

[0029] The method for controlling the grounding resistance of the present invention will be specifically described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can understand the present invention more accurately.

[0030] As mentioned in the background technology, the prior art stipulates that the grounding resistance of rail vehicles should not be higher than 4 ohms, so that the car body can be reliably grounded, but the range of grounding resistance is not specified, let alone the control measures for grounding resistance .

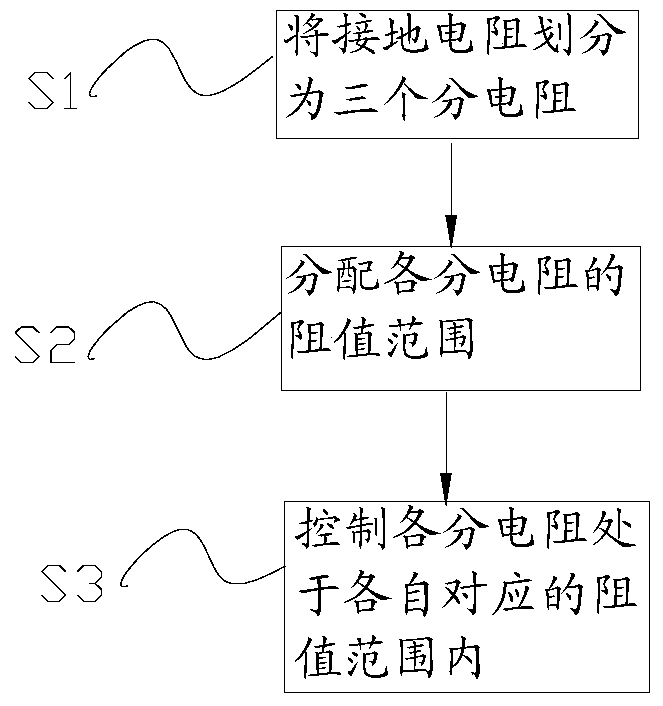

[0031] In view of the above-mentioned technical problem, the present invention provides a kind of contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com