Instrument desk tubular beam grounding device and instrument desk tubular beam

A technology for grounding device and instrument panel, which is applied in transportation and packaging, circuits or fluid pipelines, vehicle components, etc., can solve the problems of increasing the grounding resistance of electrical appliances in the instrument panel, detrimental to the safety of the whole vehicle, and heating of the pipe beam. Achieve the effect of increasing grounding reliability, reducing grounding resistance, and reducing overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

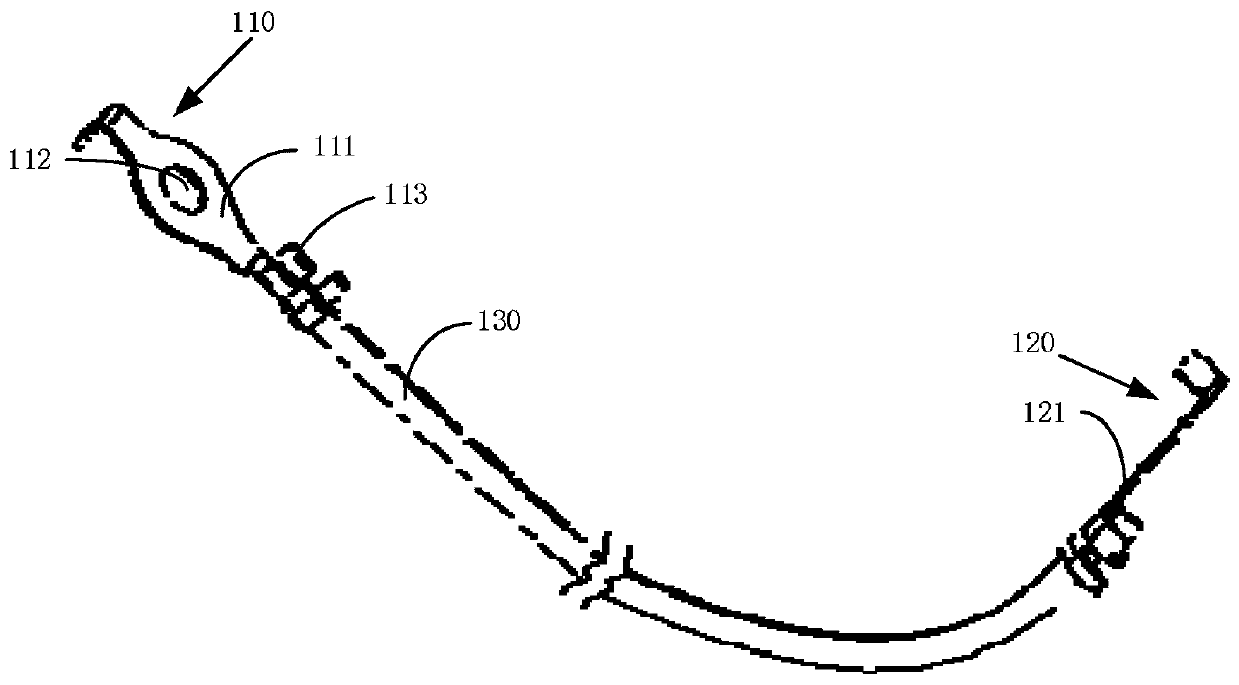

[0027] Such as figure 1 As shown, Embodiment 1 provides a grounding device for instrument panel pipe beams. The instrument panel tube beam grounding device includes: a tube beam connection end 110 , a vehicle body connection end 120 and a connecting pipe 130 ; The grounding reliability of the electrical parts in the instrument panel is increased, and the grounding resistance of the electrical appliances used in the instrument panel on the pipe beam is reduced. Reduced overheating of tube beams.

[0028] In this embodiment, the connecting pipe 130 includes an external hose and an internal conductive wire; the internal conductive wire is adapted to be connected to the pipe beam connection end 110 and the vehicle body connection end 120 after passing through the external hose electrical connection.

[0029] In this embodiment, the pipe beam connecting end 110 includes a first connecting plate 111; the first connecting plate 111 is provided with a fixing hole 112 suitable for p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com