Aluminum alloy profile for ship bodies

A technology of aluminum alloy profiles and hulls, applied in the direction of hulls, hull bulkheads, hull parts, etc., can solve problems that affect work efficiency, affect the service life of the ship, and the hull is easily damaged, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

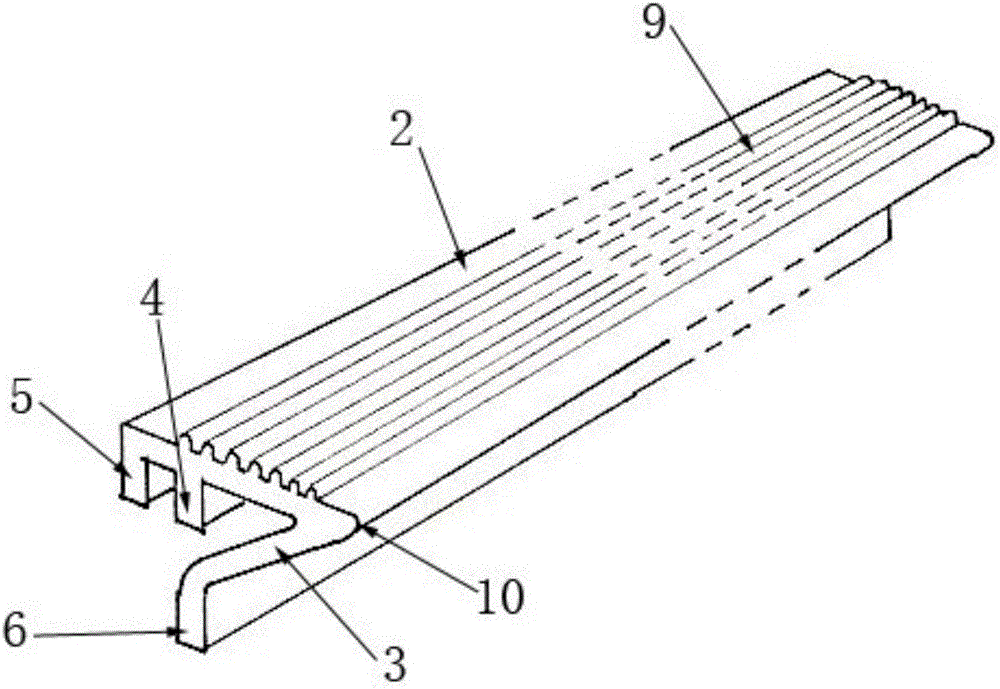

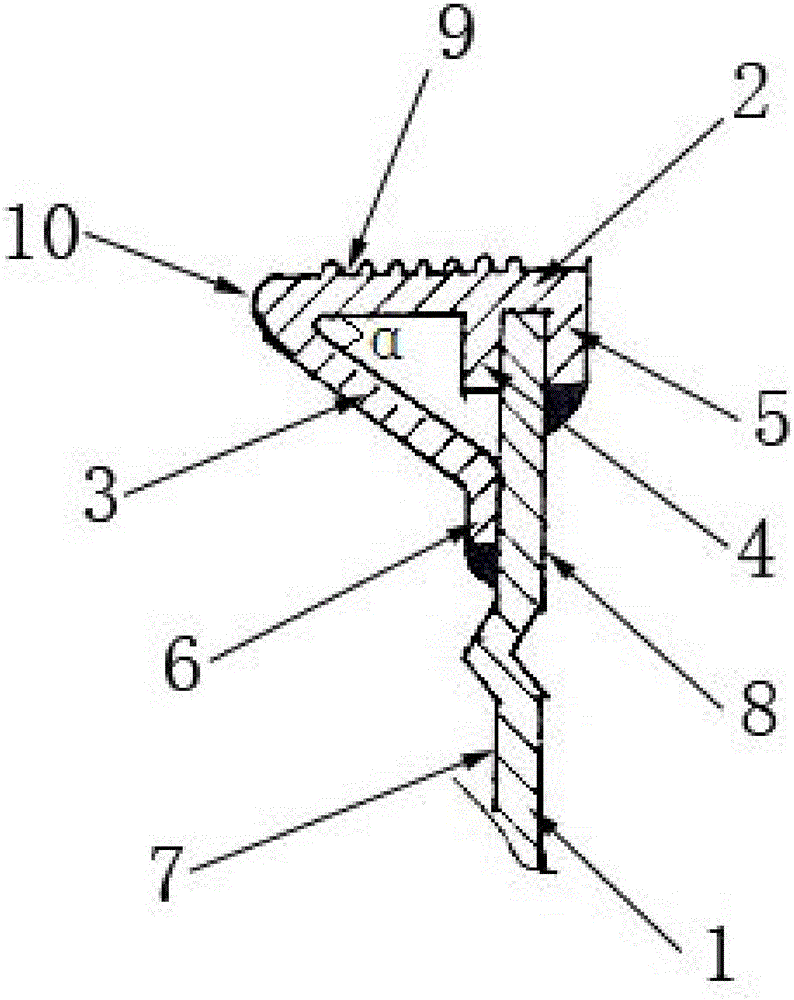

[0020] Such as Figure 1-2 As shown, an aluminum alloy profile used for the hull is installed on the upper end of the ship's side wall panel 1, and is a reinforcing edge strip used for the upper edge of the ship's side wall panel 1. The aluminum alloy profile is an integrally formed strip structure , the cross section of the aluminum alloy profile is an open triangle, the open triangle has side walls I2 and II3, and the angle α between the side wall I1 and the side wall II3 is 30°-45°. The end of the inner surface of the side wall I2 is provided with ribs I4 and II5 downwards, and the ribs I4 and II5 are respectively perpendicular to the side wall I2, and the distance between the ribs I4 and II5 matches the wall thickness of the side wall plate 1. A slot shape is formed between the ribs I4 and II5, which is clamped on the upper end of the ship's side wall 1, and the end of the side wall II3 has a downward corner extension 6, and one side of the corner extension 6 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com