Sewage treatment plant classification deep treatment system

A sewage treatment plant and advanced treatment technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of poor versatility of the sewage treatment system, and achieve improved practicability, Reduce the cost of investment and improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

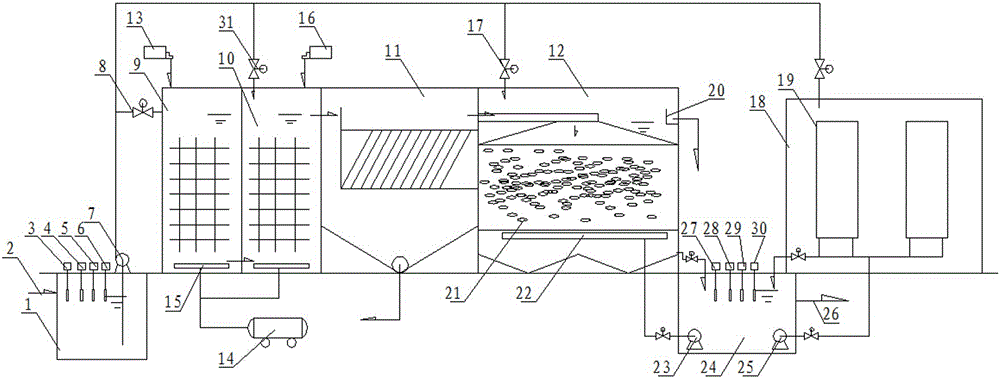

[0032] The classified advanced treatment system of the sewage treatment plant in this embodiment includes a collection pool for collecting sewage, the collection pool is equipped with a lift pump, the outlet of the lift pump is connected to an output pipeline, and the output pipeline is connected to a separate The phosphorus removal tank inlet valve, the flocculation tank inlet valve, the biological filler filter tank inlet valve and the ultrafiltration tank inlet valve connected with the phosphorus removal tank, the flocculation tank, the biofill filter tank and the ultrafiltration tank; The pool is connected with the flocculation tank, the flocculation tank is connected with the sedimentation tank, the sedimentation tank is connected with the biological filler tank, the outlet of the biological filler tank is connected with the clear water tank, and the ultrafiltration unit is arranged in the ultrafiltration tank. The outlet of the ultrafiltration tank communicates with the c...

Embodiment 2

[0034] The classified advanced treatment system of the sewage treatment plant in this embodiment includes a collection pool for collecting sewage, the collection pool is equipped with a lift pump, the outlet of the lift pump is connected to an output pipeline, and the output pipeline is connected to a separate The phosphorus removal tank inlet valve, the flocculation tank inlet valve, the biological filler filter tank inlet valve and the ultrafiltration tank inlet valve connected with the phosphorus removal tank, the flocculation tank, the biofill filter tank and the ultrafiltration tank; The pool is connected with the flocculation tank, the flocculation tank is connected with the sedimentation tank, the sedimentation tank is connected with the biological filler tank, the outlet of the biological filler tank is connected with the clear water tank, and the ultrafiltration unit is arranged in the ultrafiltration tank. The outlet of the ultrafiltration tank is connected with the c...

Embodiment 3

[0036] Based on the second embodiment, the phosphorus removal tank and the flocculation tank are respectively equipped with a phosphorus removal dosing device and a flocculation dosing device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com