Electroplating device

An electroplating device and electroplating solution technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problem of limited effect of anode material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

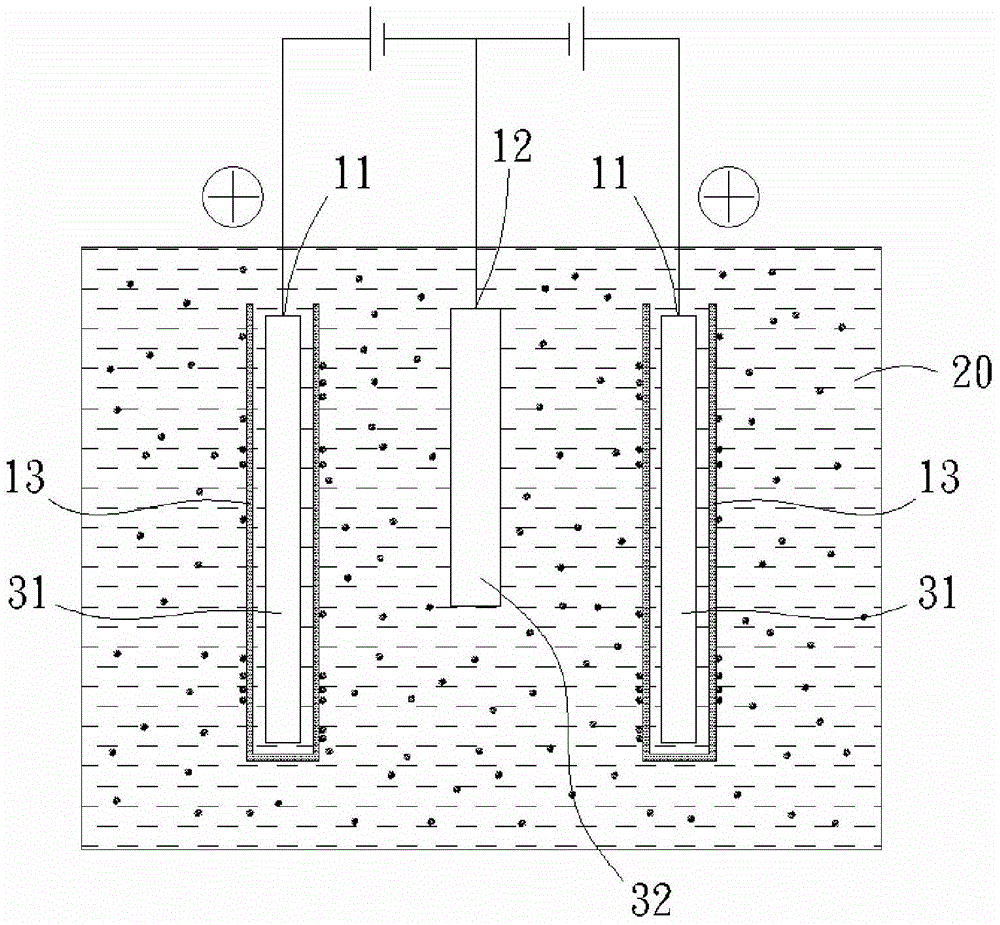

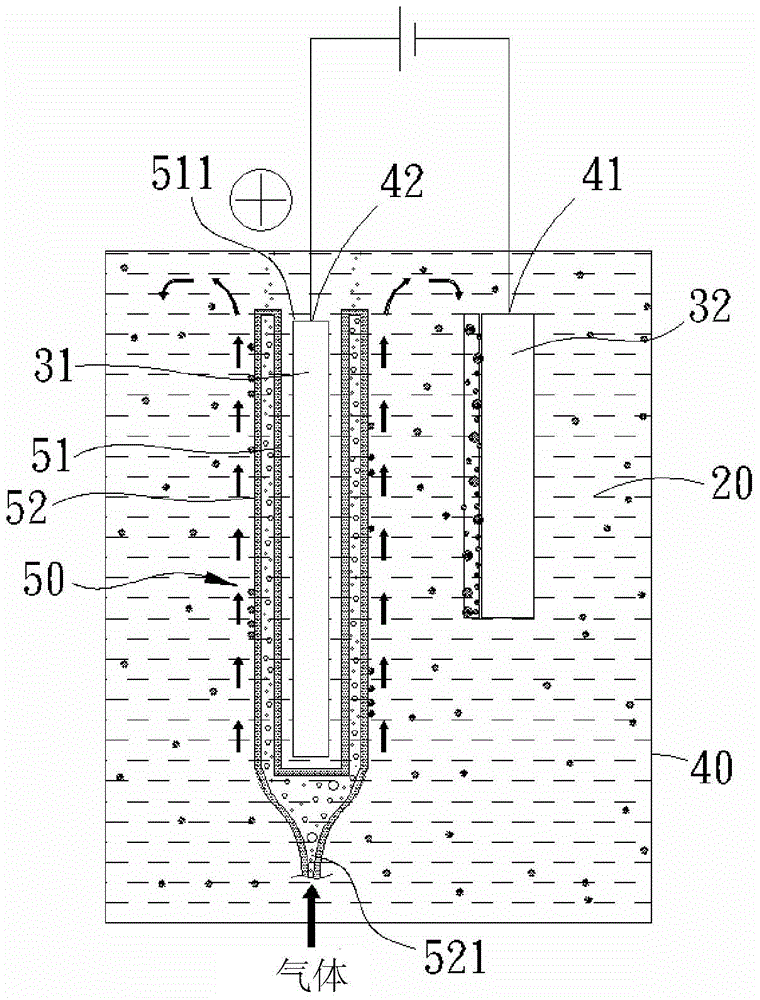

[0036] The present invention mainly provides an electroplating device that can effectively reduce the loss of anode materials and additives, and is especially suitable for electroplating operations using organic additives, such as figure 2 Schematic diagram of the electroplating device structure of the first embodiment of the present invention, image 3 As shown in the cross-sectional view of the structure of the compound filter bag in the present invention, the electroplating device of the present invention basically has a tank body 40 for containing the electroplating solution 20, and at least one negative electrode for connecting the object to be plated 32 is provided in the tank body 40. electrode 41, and at least one positive electrode 42 for connecting to the anode material 31.

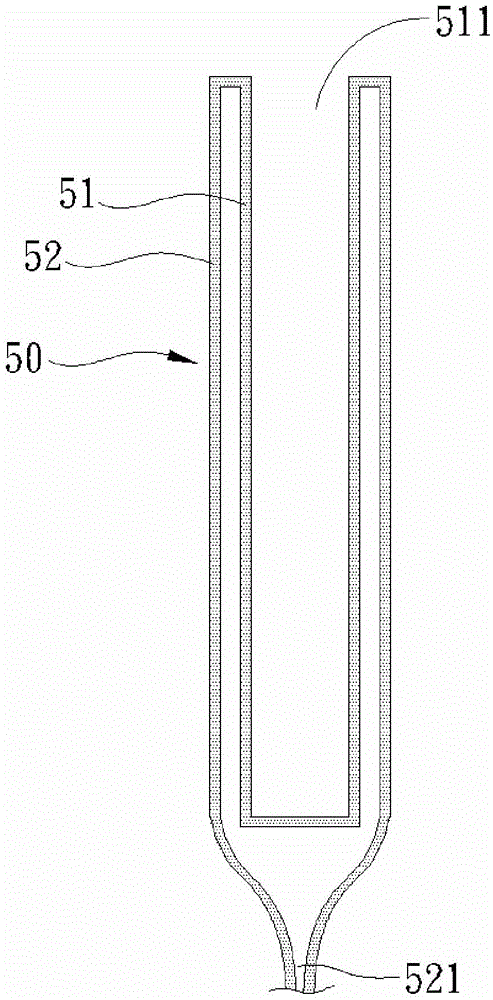

[0037] The present invention is characterized in that: the electroplating device is provided with a composite filter bag 50 that can penetrate the electroplating solution at the at least one po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com