An electric auxiliary power automatic water adding device

An automatic water-filling and electric-assisted technology, applied in the configuration of water supply devices, water supply devices, and water supply pools, etc., can solve the problems of high circuit failure rate, inapplicability, and cannot be counted as a constant-position water supply device, etc., to reduce the circuit failure rate. , to avoid the effect of frequent switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

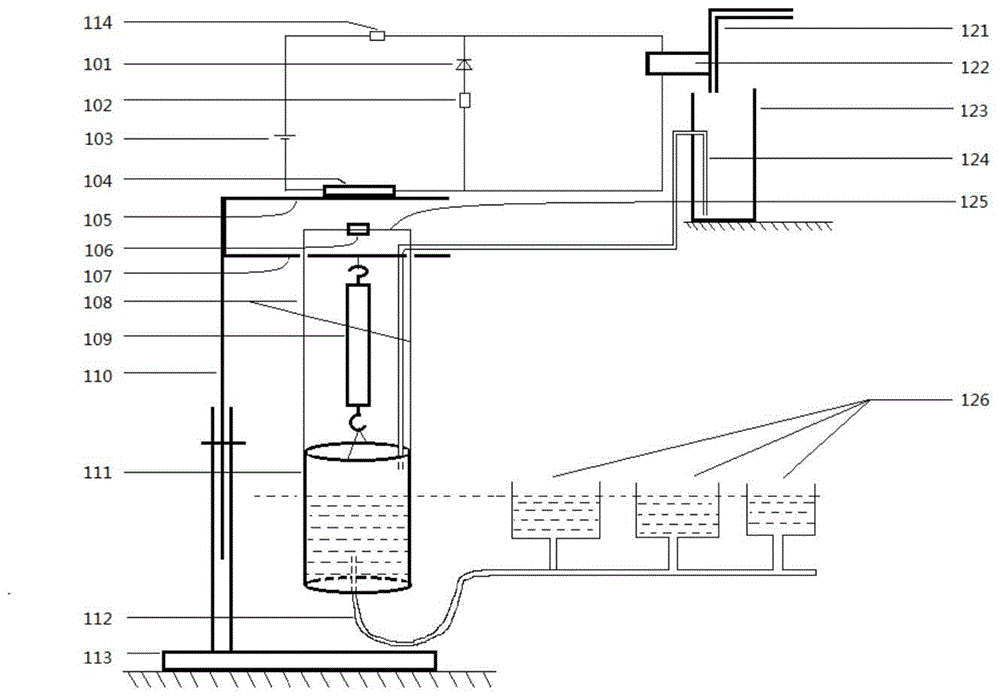

[0036] Such as figure 1 As shown, an automatic water filling device with electric auxiliary power includes a bracket, a spring 109, a bucket 111, a normally open magnetic switch, a water delivery module, a water pipe 121, a normally closed electromagnetic water valve 122, and a normally open magnetic control switch. The circuit of the switch and the normally open magnetic control switch connects the water bucket 111 and the hose 112 of the downstream water consumption device 126; the upper end of the spring 109 is hung on the bracket, and the lower end hangs the water bucket 111; the inside of the water bucket 111 is a cylinder or a cuboid, horizontally horizontal The size of the cross-sectional area is set so that the water weight per unit depth equals the force required for the deformation of the spring 109 units, that is, K=ρgs (k is the elastic coefficient of the spring 109, g is the acceleration of gravity, and s is the transverse direction of the horizontal direction insi...

Embodiment 2

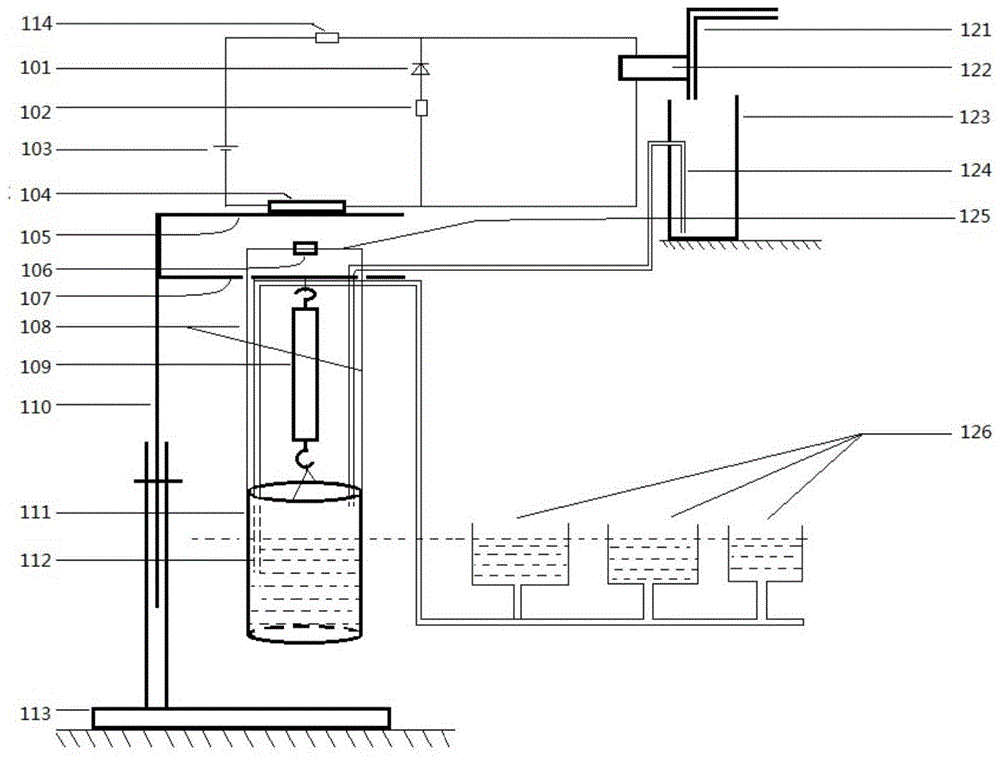

[0047] refer to figure 2 , the structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that one end of the hose 112 of this embodiment is suspended from the lower beam 107 of the support and stretched into the water of the bucket 111, and one end is connected to the water of the downstream water consumption device 126, When using for the first time, the hose should exhaust the air and then siphon the water in the bucket 111 into the downstream water consumption device 126; the hose 112 does not touch the bucket wall, bucket bottom or bucket handle of the bucket 111;

[0048] The normally open magnetic control switch in this embodiment can also be changed to a normally closed magnetic control switch, and the corresponding normally closed electromagnetic water valve should be changed to a normally open electromagnetic water valve; in addition, the circuit controlled by the magnetic control switch can not It is directly connec...

Embodiment 3

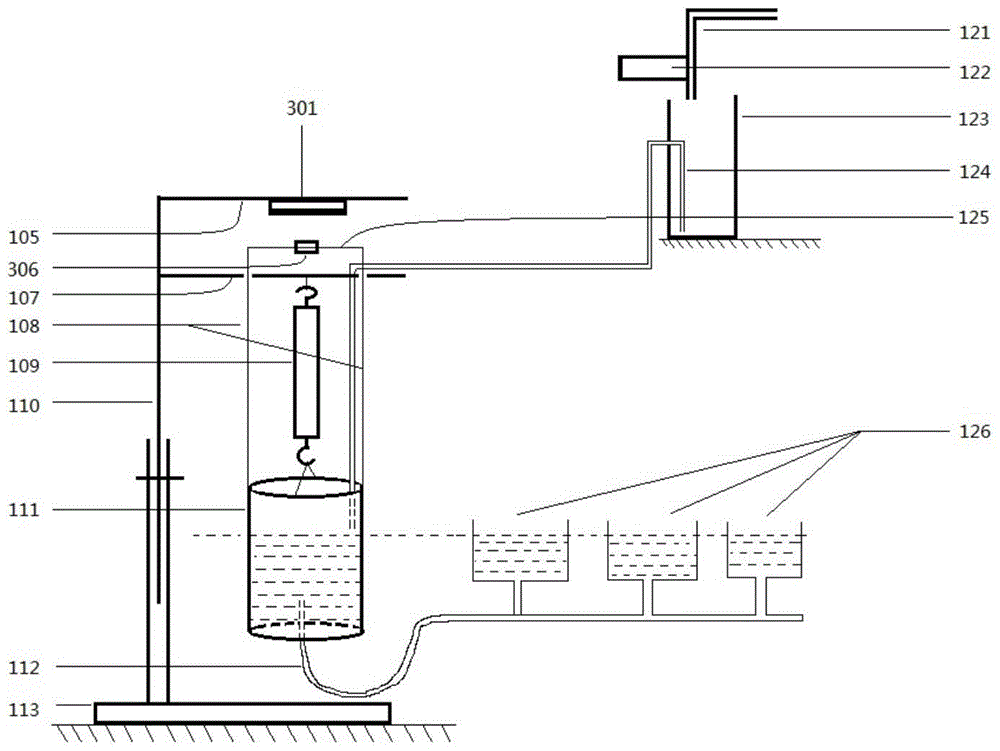

[0050] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is: 1. Refer to Figure 3-1 , the proximity switch of the present embodiment is a normally open capacitive proximity switch 301, a DC two-wire type; two, refer to Figure 3-2 , the circuit connection method is slightly different: the circuit where the normally open capacitive proximity switch 301 is located is not directly connected with the electromagnetic water valve 122, but forms a control circuit with the electromagnet of the electromagnetic relay 001, and then controls the electromagnetic water valve through the electromagnetic relay 001 The working circuit where 122 is located;

[0051] Capacitive proximity switch 301 installation method: refer to Figure 3-1 , the normally open capacitive proximity switch 301 is fixed on the lower surface of the upper beam 105, and the dielectric substance 306 is sheathed on the horizontal thin rod 125 such as an iron r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com