Screen pipe horizontal well production profile testing apparatus and testing method for same

A testing device and horizontal well technology, which is applied in the directions of surveying, earthwork drilling and production, wellbore/well components, etc., can solve the problems of high construction risk, limited applicable well conditions, and high testing costs, so as to reduce operating construction costs and improve measurement accuracy High, construction safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments. However, those skilled in the art should know that the present invention is not limited to the specific embodiments listed, as long as it conforms to the spirit of the present invention, it should be included in the protection scope of the present invention.

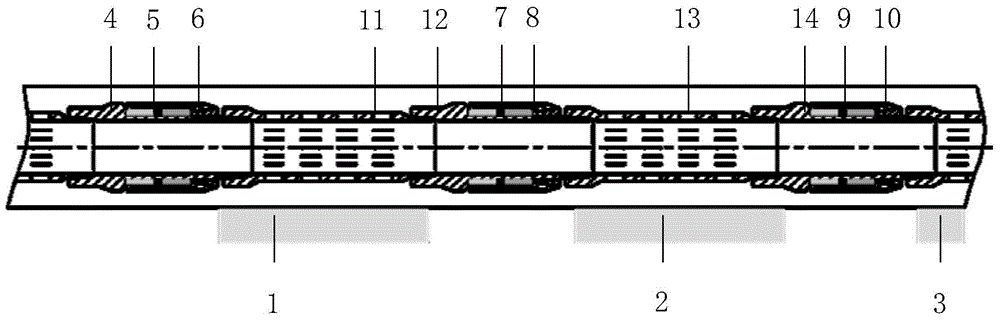

[0016] See attached figure 1 . The screen tube horizontal well production profile testing device of the present invention comprises a screen tube 11 and a release device (the applicant for this patent has applied for a patent separately for the "release device", and the structure and function of the "release device" will not be repeated here), The release device includes release device I14, release device II12, and release device III4. Between release device I14, release device II12, and release device III4, a screen 11 of appropriate length is installed according to the length of the pay zone and interlayer in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com