Thermal expansion stone splitting agent equal proportion structure large-area stone splitting method

A rock-cracking agent and thermal expansion technology, which is applied in the interdisciplinary field of material science and engineering technology, can solve the problems of rock-cracking agent waste, etc., and achieve the effects of fast rock-cracking, lower economic costs, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

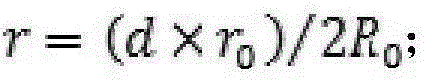

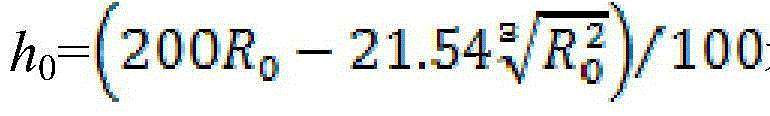

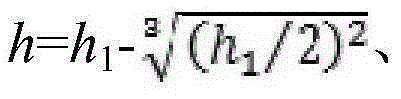

[0022] In a quarry, choose the side length R 0 Cube limestone with dimensions 1.2m, according to the formula Drilling depth h at the center of the rock 0 A hole of 1.05m was drilled, and a stone hole with a radius of 10mm was drilled, and the thermal expansion rock cracking agent was filled for a rock cracking test. The rock could not be cracked, and the drilling radius was increased in turn until the rock could be completely cracked and the distance between the cracked stones reached 15cm. The measured The optimum drilling radius is 20mm. In this quarry, according to the construction requirements, the same type of limestone needs to be cracked. Its shape is close to a cuboid, and its size is about 3m×4m×5m. According to the requirements of the construction personnel on site, the drilling plane S is 4m×5m. According to the rock cracking requirements, the rock cracking technicians evenly distribute the drilling positions on the drilling plane S according to the drilling dist...

Embodiment 2

[0024] In a quarry, choose the side length R 0 Cube limestone with dimensions 1.2m, according to the formula Drilling depth h at the center of the rock 0 A hole of 1.05m was drilled, and a stone hole with a radius of 10mm was drilled, and the thermal expansion rock cracking agent was filled for a rock cracking test. The rock could not be cracked, and the drilling radius was increased in turn until the rock could be completely cracked and the distance between the cracked stones reached 15cm. The measured The optimum drilling radius is 20mm. In this quarry, according to the construction requirements, the same type of limestone needs to be cracked. The construction area is close to a rectangle, with a size of about 2m×4m. According to the requirements of the construction personnel on site, the 4m×2m plane is used as the drilling plane S. Rock cracking technology According to the rock-cracking requirements, the personnel evenly distributed 12 drilling positions on the drilling ...

Embodiment 3

[0026] In a quarry, choose the side length R 0 Cubic limestone of size 0.8m, according to the formula Drilling depth h at the center of the rock 0 A hole of 0.68m was drilled, and a stone hole with a radius of 8mm was drilled, and the thermal expansion rock cracking agent was filled for a rock cracking test. The rock could not be cracked, and the drilling radius was increased in turn until the rock could be completely cracked and the distance between the cracked stones reached 25cm. The measured The optimum drilling radius is 14mm. In this quarry, according to the construction requirements, it is necessary to crack the same type of limestone. Its shape is close to a cuboid, and its size is about 6m×8m×5m. According to the requirements of the construction personnel on site, the 6m×8m plane is used as the drilling plane S. According to the rock cracking requirements, the rock cracking technicians evenly distribute the drilling positions on the drilling plane S according to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com