Scroll compressor

A scroll compressor, scroll technology, applied in the direction of rotary piston machinery, rotary piston pump, mechanical equipment, etc., can solve the problems of reducing compressor operating efficiency, noise, large compressor initial torque, etc. The effect of improving startup reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

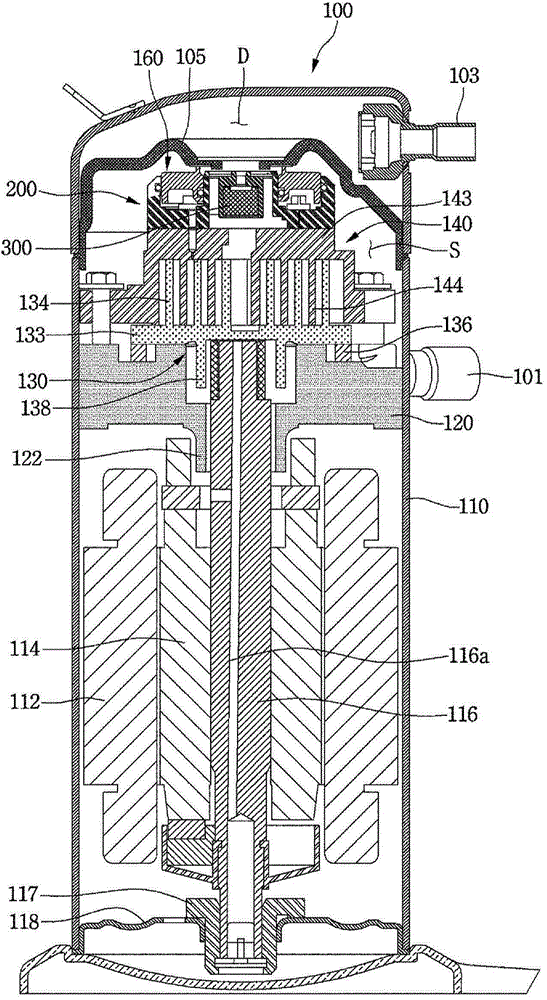

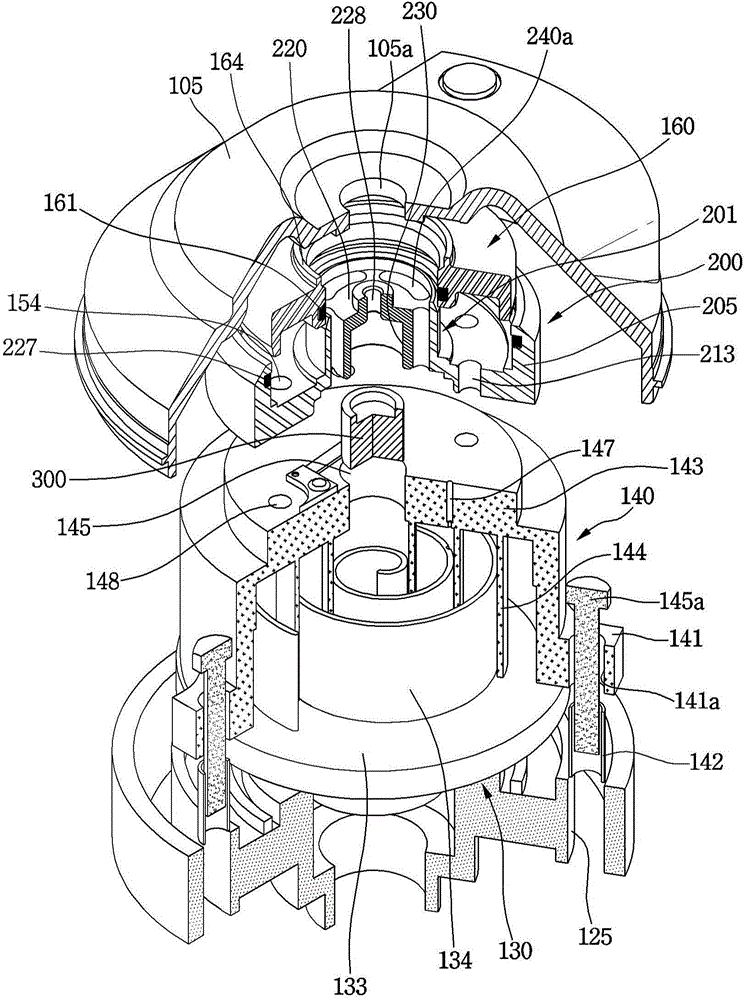

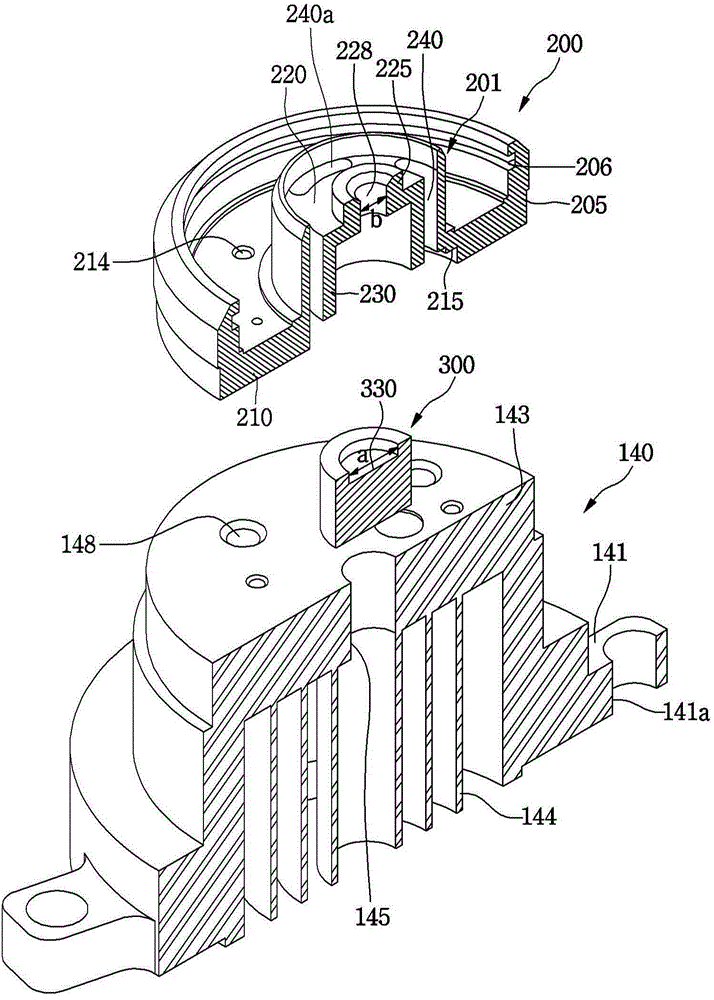

[0061] figure 1 To show a cross-sectional view of the structure of the scroll compressor of the first embodiment of the present invention, figure 2 In order to explode a cross-sectional view showing a part of the structure of the scroll compressor of the first embodiment of the present invention, image 3 In order to show an exploded perspective view of the structure of the back pressure part and the fixed scroll of the first embodiment of the present invention, Figure 4 It is a diagram showing the structure of the opening and closing device of the first embodiment of the present invention.

[0062] Reference Figure 1 to Figure 3 , The scroll compressor 100 of the first embodiment of the present invention includes a casing 110 for forming a suction space S and a discharge space D.

[0063] In detail, a cover 105 is provided on the upper part of the inside of the housing 110. With the cover 105, the internal space of the housing 110 is divided into a suction space S and a discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com