Double-draught-fan type fresh air purifying machine

A purification machine and double fan technology, applied in heating methods, mechanical equipment, space heating and ventilation, etc., can solve the problems of secondary pollution, large wind resistance, high filter element replacement frequency, etc., and achieve reduced size and power requirements, replacement The effect of frequency reduction and filter element thickness reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

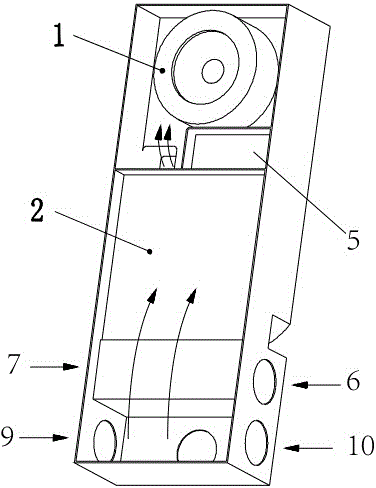

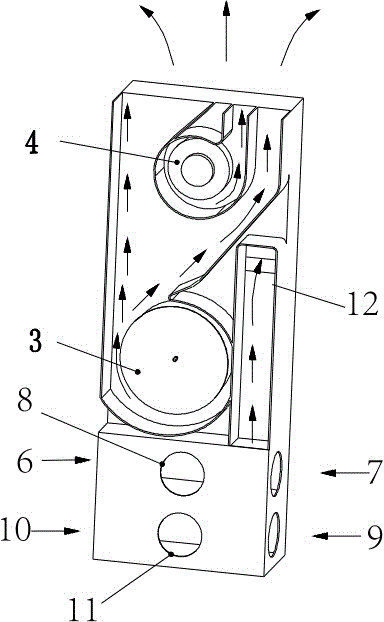

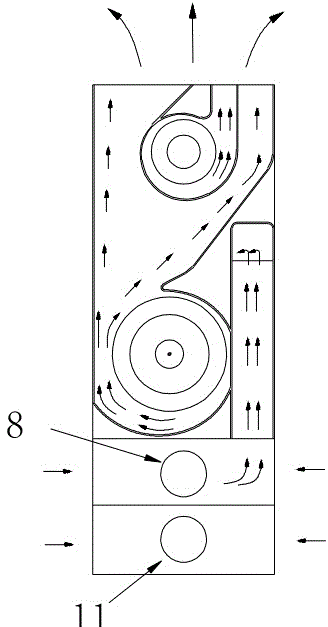

[0065] Example 1, such as Figures 1 to 7 As shown, 1—fresh air filter module, 2—return air filter module, 3—return air fan, 4—fresh air fan, 5—electric control device chamber, 6—right fresh air outlet, 7— —Left fresh air outlet, 8—Back fresh air outlet, 9—Left return air outlet, 10—Right return air outlet, 11—Back side return air outlet, 12—Fresh air channel.

[0066] The double fan type fresh air purifier adopts two fans, the fresh air fan is arranged in the fresh air chamber, the return air fan is arranged in the return air chamber, and the fresh air chamber and the return air chamber are set independently. Vertical design, also available in hanging or horizontal design.

[0067] The fresh air fan divides the fresh air chamber into a fresh air inlet chamber and a fresh air outlet chamber, and the return air fan divides the return air chamber into a return air inlet chamber and a return air outlet chamber; the fresh air outlet connects to the fresh air chamber, and the retu...

Embodiment 2

[0078] Example 2, such as Figure 10 , 11 , 12, 13 are the double fan fresh air purifiers of another kind of structure.

[0079] The double fan type fresh air purifier adopts two fans, the fresh air fan is arranged in the fresh air chamber, the return air fan is arranged in the return air chamber, and the fresh air chamber and the return air chamber are set independently. Vertical design, also available in hanging or horizontal design.

[0080] The fresh air fan divides the fresh air chamber into a fresh air inlet chamber and a fresh air outlet chamber, and the return air fan divides the return air chamber into a return air inlet chamber and a return air outlet chamber; the fresh air outlet connects to the fresh air chamber, and the return air outlet connects to the return air chamber , The fresh air cavity and the return air cavity are connected to the air outlet. Both the fresh air fan and the return air fan are centrifugal fans, and the fresh air chamber and the return a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com