Insulation formwork for winter construction of heating furnace support beams

A technology of thermal insulation formwork and support beams, which is applied in the direction of lining repair, etc., can solve the problems such as the impact on the quality of support beams, and achieve the effects of good heating effect, high strength and fire resistance, and high fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the drawings and embodiments.

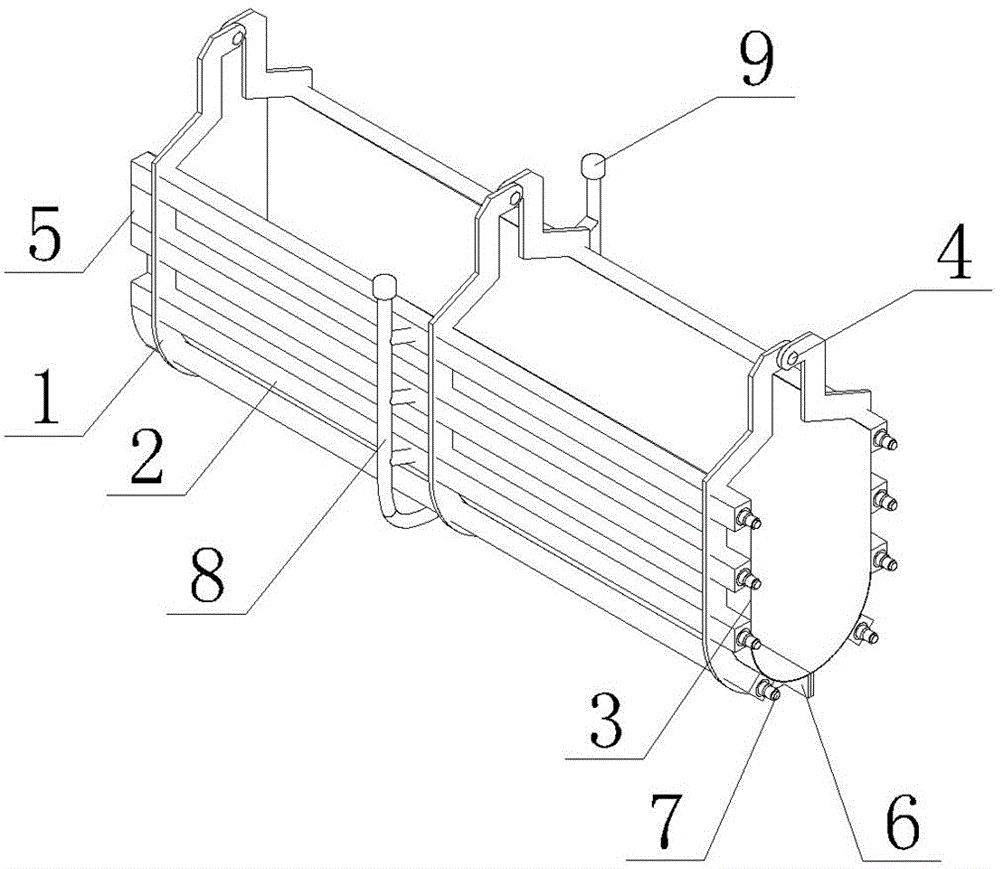

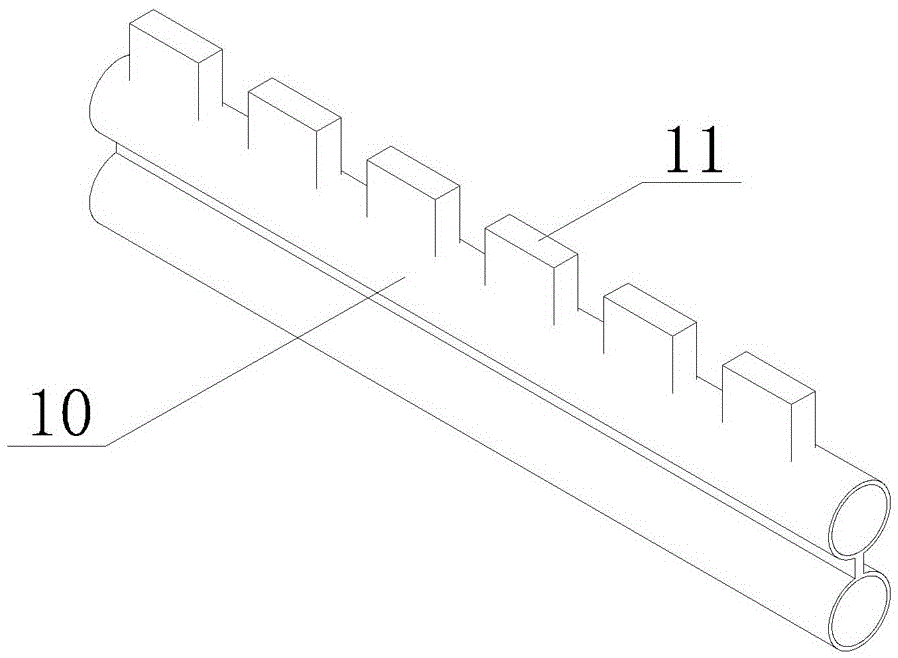

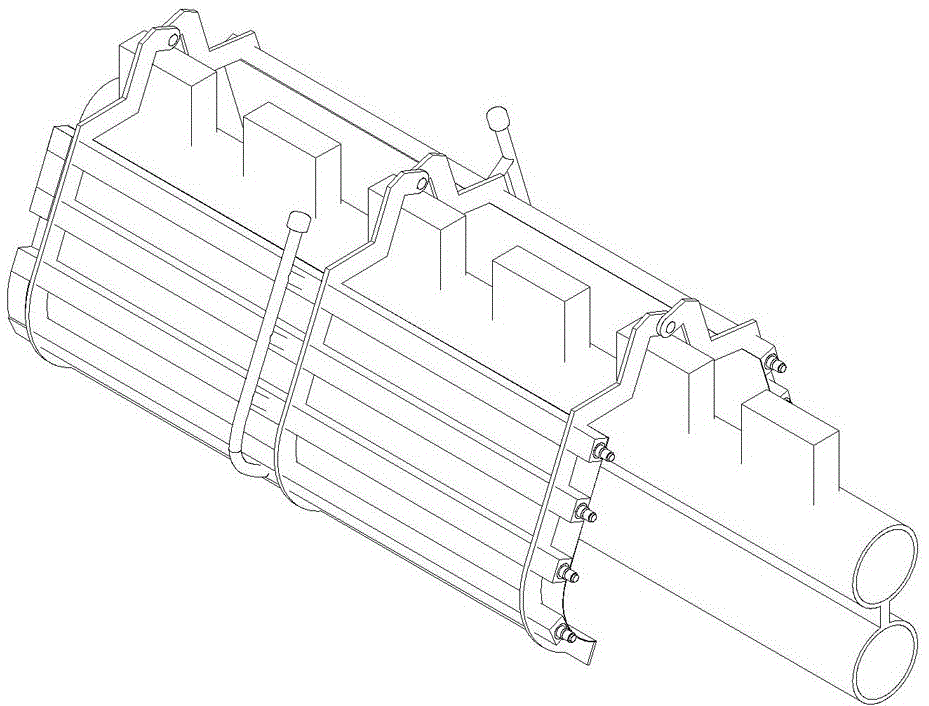

[0033] Such as figure 1 , image 3 , Figure 4 with Figure 5 As shown, an insulation template for winter construction of a supporting beam of a heating furnace includes two steel structure insulation boards respectively arranged on both sides of the supporting beam steel structure 10 during operation, and the steel structure insulation board includes a cast product with the supporting beam 13 A steel plate 3 with a single-sided contour that is compatible with multiple square pipes 2 fixed on the outside of the steel plate 3 (square pipe 2 is used instead of a general round pipe, which is not only convenient to fix on the steel plate 3 but also has a larger contact area) and more A vertical rib 1, a branch pipe 8 connecting all the square pipes 2, and the square pipe 2 is provided with a heating mechanism and the opening is closed. The top of the branch pipe 8 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com