Anti-seepage gel-electrophoresis precast gel shell

A gel electrophoresis and prefabricated gel technology, applied in the direction of material analysis, measuring devices, instruments, etc. by electromagnetic means, can solve problems such as the decrease of elasticity and flatness, the leakage of premixed liquid, and the increase in the workload of researchers, and achieve easy solution Effects of leakage, saving energy and cost, increasing efficiency and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

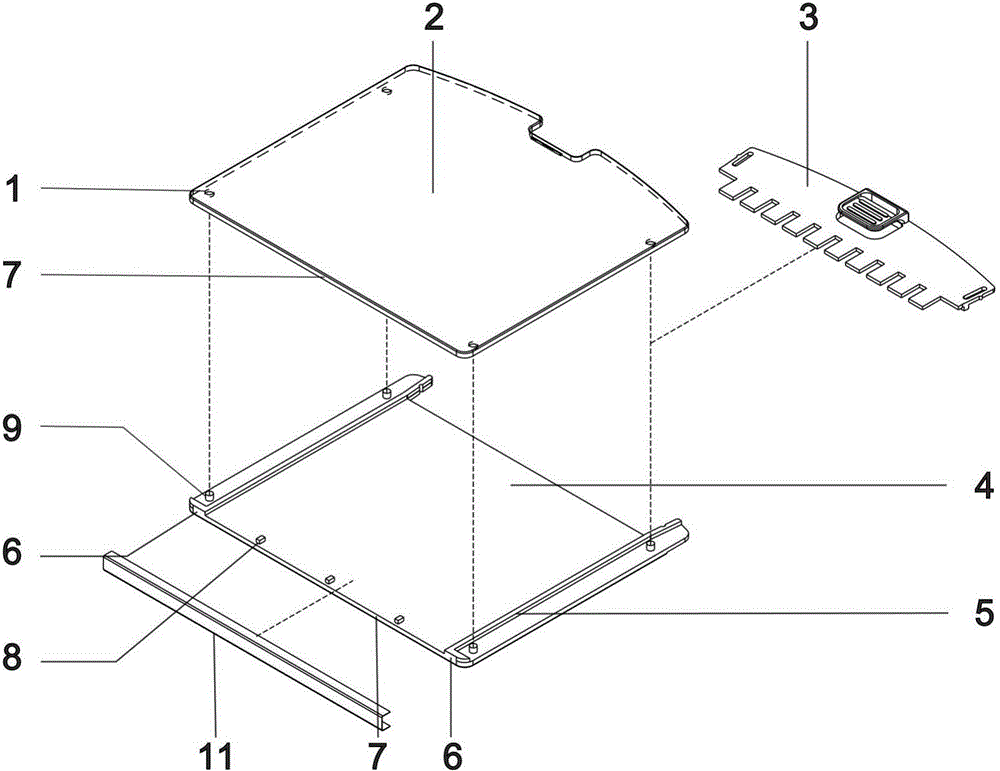

[0021] Example 1: Combining figure 1 and Figure 5 To illustrate this embodiment, the prefabricated gel shell of polyacrylamide gel electrophoresis in this mode includes a positioning groove 1, a front plate 2, a ten-hole slot 3, a rear plate 4, a vertical connecting edge 5, a horizontal connecting edge 6, and a bottom surface Plane 7, supporting column 8, positioning column 9, sealing mucosa 11, and horizontal joint crease 12. The plane of the horizontal connecting edge 6 is in the same plane as the bottom plane 7 of the prefabricated rubber shell. The horizontal connecting ribs 6 are outside the vertical connecting ribs 5 on both sides of the prefabricated plastic shell. The length of the horizontal connecting rib 6 on one side is 1-10mm. The sealing mucosa 11 is closely attached to the horizontal connecting rib and the bottom platform. The surrounding mucosa of the seal is upturned and close to the plate 1-10mm. This embodiment increases the contact area between the se...

Embodiment 2

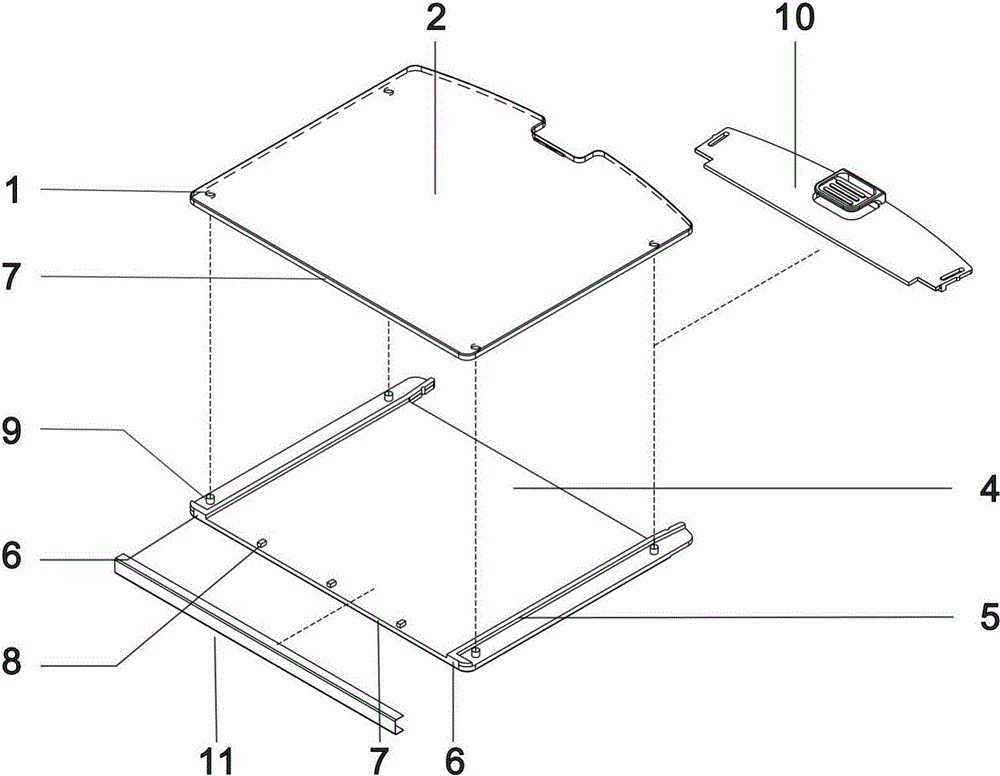

[0022] Embodiment 2: The difference between this embodiment and Embodiment 1 is: as figure 2 As shown, the housing of the anti-leakage polyacrylamide gel electrophoresis precast gel contains single-hole slots instead of ten-hole slots. Others are the same as in Example 1. This embodiment is used for two-dimensional electrophoresis.

Embodiment 3

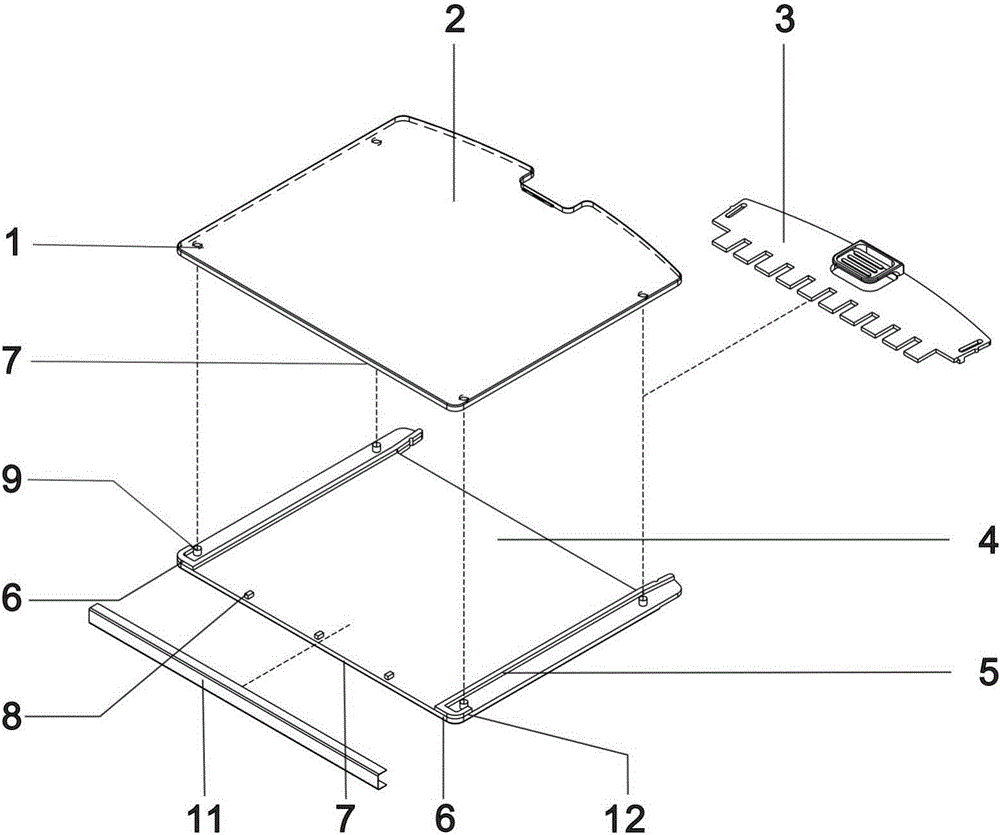

[0023] Embodiment 3: The difference between this embodiment and Embodiment 1 is: as image 3 As shown, the shell of the anti-leakage polyacrylamide gel electrophoresis prefabricated gel contains horizontally connected knuckles, forming a hook shape, and the sealing mucosa 11 is correspondingly extended and adhered to it, further Increase the bonding area between the sealing mucosa and the connecting rib. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com