Bearing platform waterscape

A technology of waterscape and concrete, applied in the direction of decorative art, special decorative structures, etc., can solve the problems of water leakage and water seepage maintenance, difficult and other problems, achieve the effect of reducing maintenance costs in the later period, solving easy leakage, and eliminating water leakage and water seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

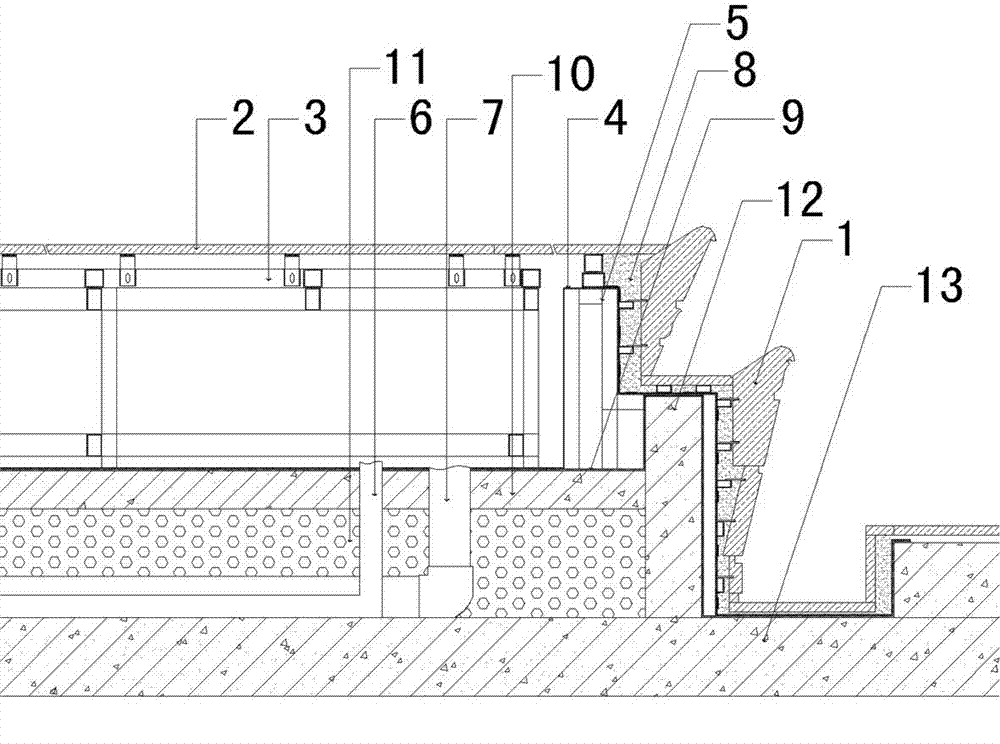

[0023] Example: such as figure 2 Shown: a platform waterscape, which includes stainless steel sheet, side port stone 1, pool surface stone 2, stainless steel skeleton 3, stainless steel structure 5, water supply pipe 6, water outlet pipe 7 waterproof mortar 8, JS waterproof layer 9, concrete Leveling layer 10, concrete pool wall 12, concrete floor slab 13.

[0024] A gravel cushion 11 and a concrete leveling layer 10 are successively laid on the concrete floor 13; the concrete leveling layer 10 is a fine stone concrete leveling layer. The stainless steel structure 5 is installed on the inner side of the concrete pool wall 12, fixed on the concrete leveling layer 10, and connected through embedded parts; the concrete pool wall 12 is fixed on the concrete floor 13 through pre-planted bars. The stainless steel sheet is laid on the surface of the concrete leveling layer 10, the stainless steel structure 5, and the concrete pool wall 12, and the stainless steel liner 4 is formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com