USB plug with forward and reverse insertion functions

A forward and reverse insertion and plug technology, which is applied in the manufacture of contact boxes/bases, electrical components, coupling devices, etc., can solve the problems of loose terminal group stability and unsatisfactory holding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] This application uses a USB3.1 Type C plug connector for the front and back insertion of the USB plug. A new type of interface that increases the transfer rate.

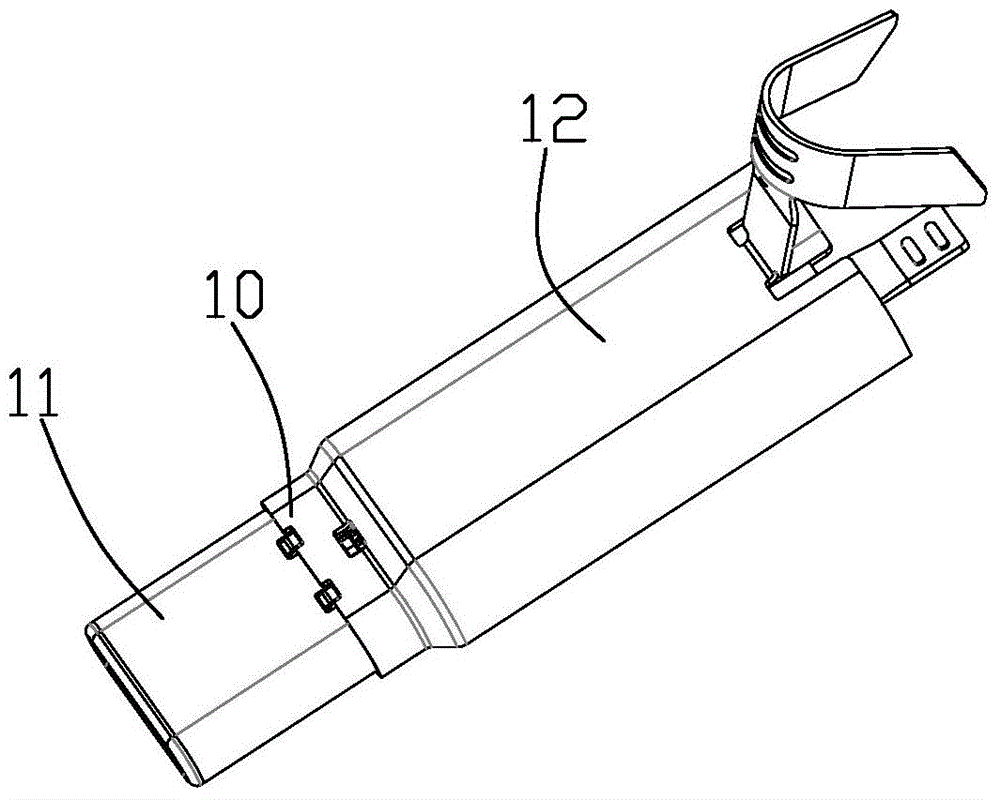

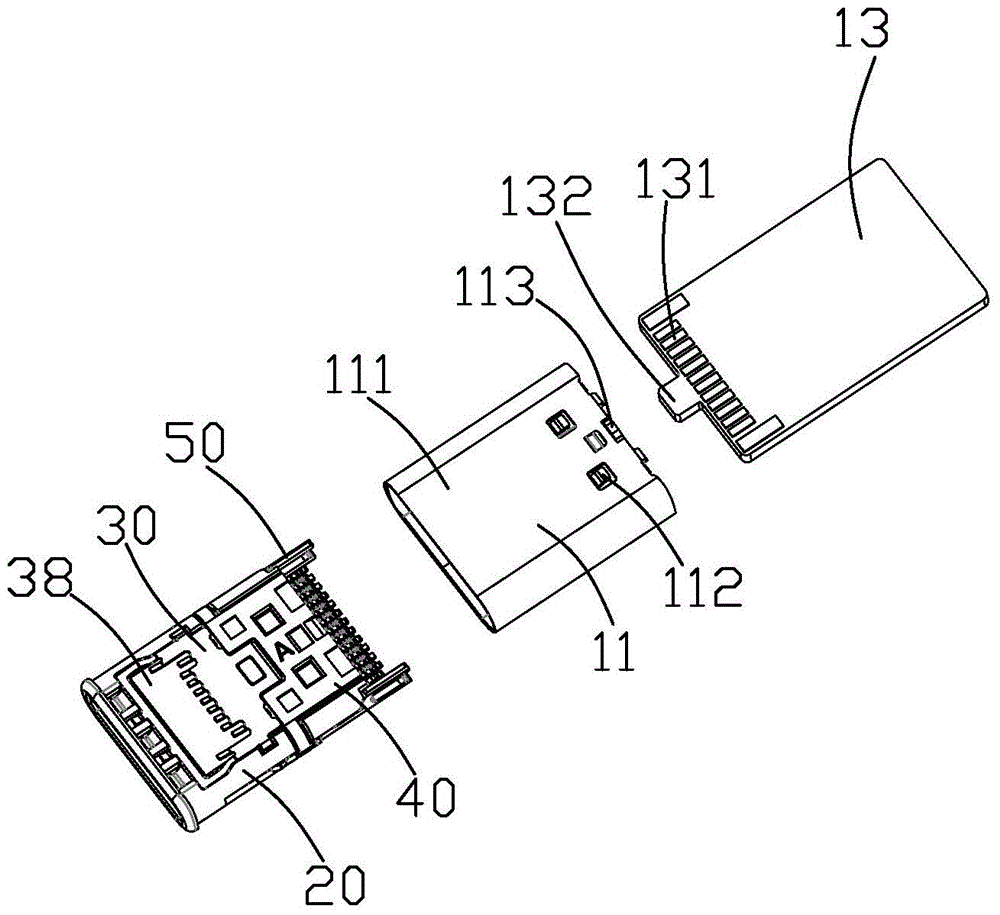

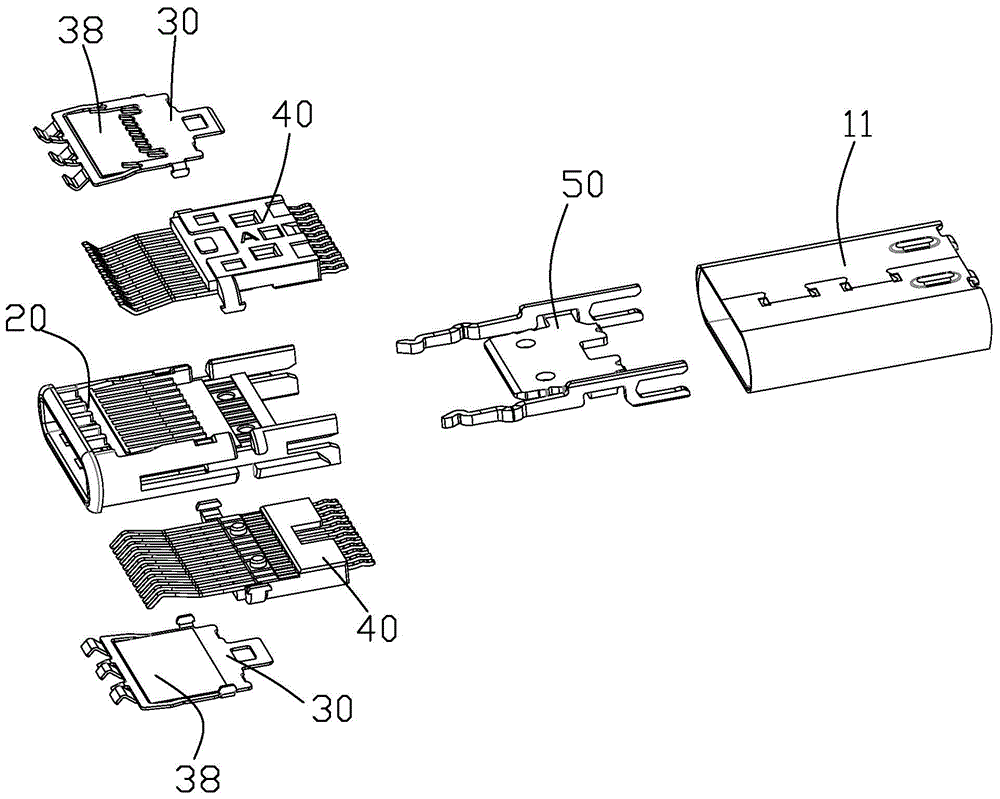

[0024] see Figure 1 to Figure 3 As shown, the USB plug of this application includes an insulating body 20, two terminal groups 40 installed on the upper and lower sides of the insulating body 20, and metal fasteners inserted from the side on the lateral sides of the insulating body 20. 50. The metal holders 30 installed on the upper and lower sides of the insulating body 20, the circuit board 13 clamped at the tail of the insulating body 20 to electrically connect the two terminal groups 40, and sleeved on the insulating body 20 The metal shell 10 outside the main body 20.

[0025] The circuit board 13 includes two rows of golden fingers 131 welded to the two terminal groups 40 on the upper and lower sides of the end, and a positioning protrusion 132 formed on the front edge of the end for the convenience o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com