Concrete filled steel tubular structure based on deformation and energy absorption principles and having multi-disaster combined protection function

A technology of steel pipe concrete and protective functions, which is applied in the direction of fire protection, earthquake resistance, building components, etc., and can solve problems such as local buckling, inner structure bearing impact, structural damage, etc., and achieve the effect of avoiding structural instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

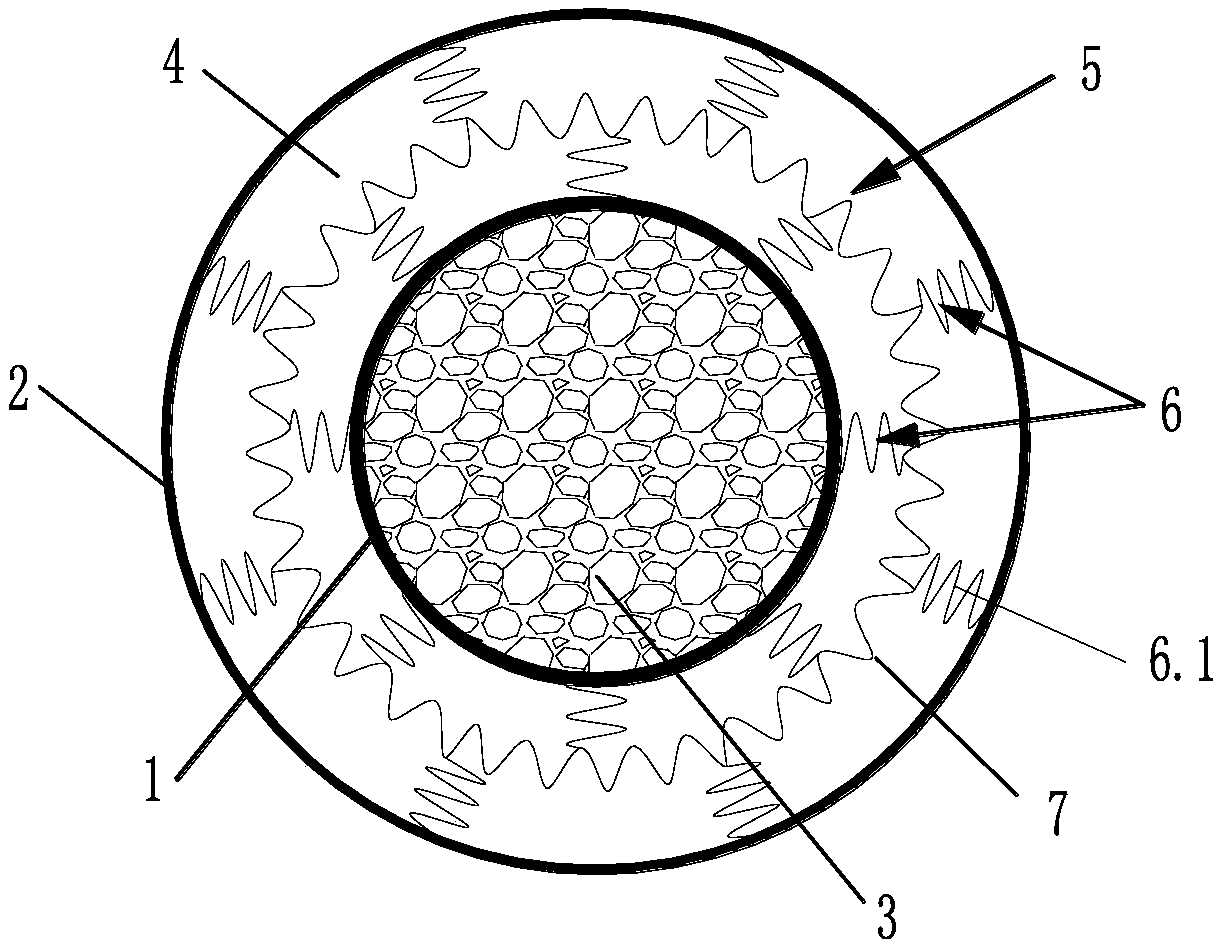

[0025] Such as figure 1 The first type of multi-hazard combined protective function steel tube concrete structure based on the principle of deformation and energy absorption shown in the present invention includes a steel tube 1 and a protective cover 2 sleeved on the outer circumference of the steel tube 1. The inner cavity of the steel tube 1 is poured with a concrete column 3. The cross-sectional shapes of the steel pipe 1 and the protective cover 2 are both circular, and the protective cover is made of a metal material with high strength and high temperature resistance (such as manganese steel). The concrete column 3 is made of conventional concrete and designed according to actual load requirements, but is not limited to conventional concrete, and can be mixed with fibers or admixtures to form high-performance concrete.

[0026] The protective cover 2 mainly plays a role of fire prevention. It prevents the flame from directly ablating the inner steel tube concrete structure a...

Embodiment 2

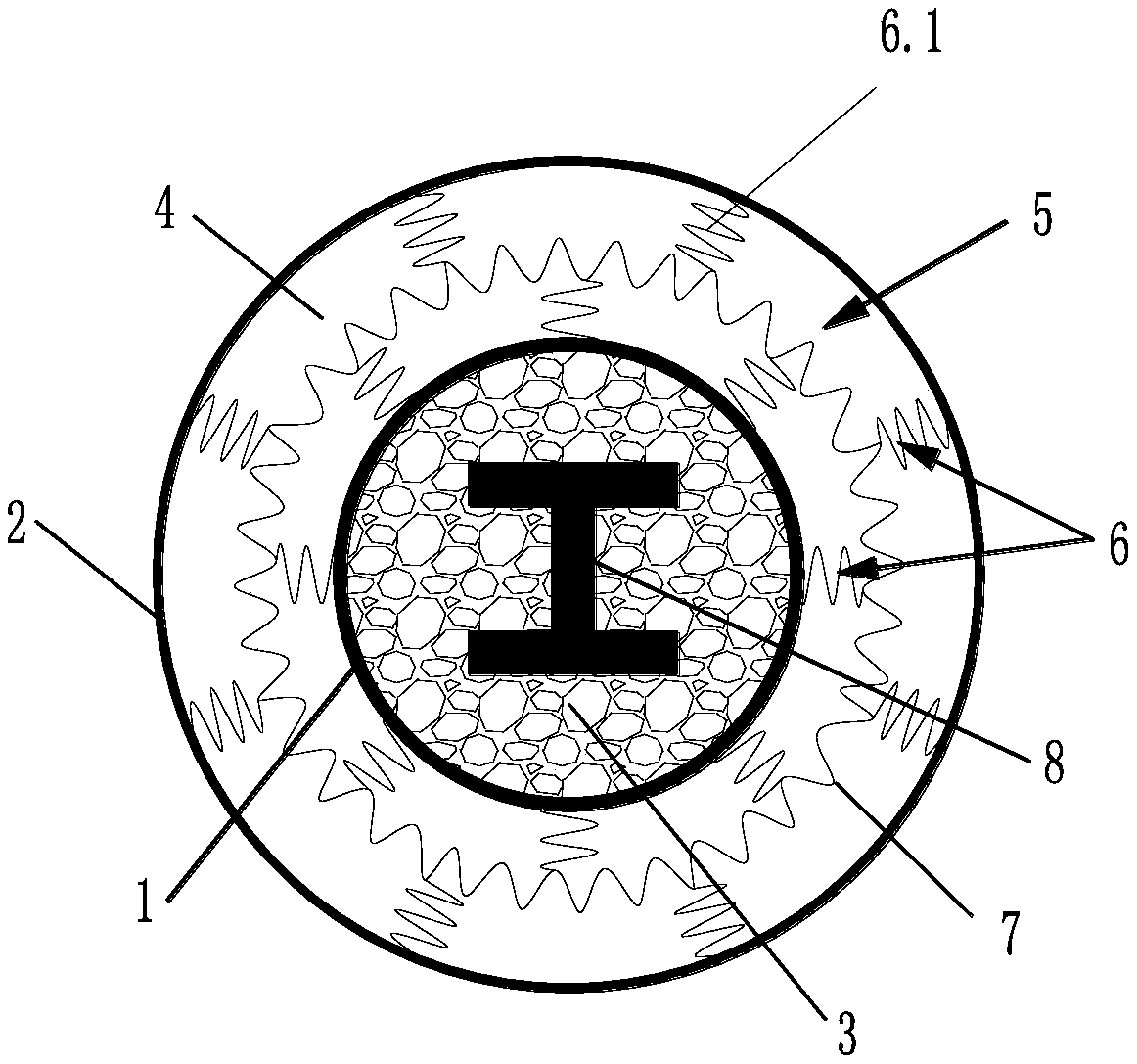

[0035] Such as figure 2 The second embodiment of the present invention shows a multi-hazard combined protective function steel tube concrete structure based on the principle of deformation and energy absorption. In this embodiment 2, on the basis of embodiment 1, a section steel 8 is embedded inside the steel tube 1 to increase the structure The overall stiffness to meet the needs of the structure when the load is large. The section steel 8 can be in the form of an I-beam. The section steel 8 is preliminarily placed before pouring the concrete column 3 in the manufacturing step 1 of the embodiment 1 and then the concrete is poured. The other manufacturing steps are the same as those of the embodiment 1.

Embodiment 3

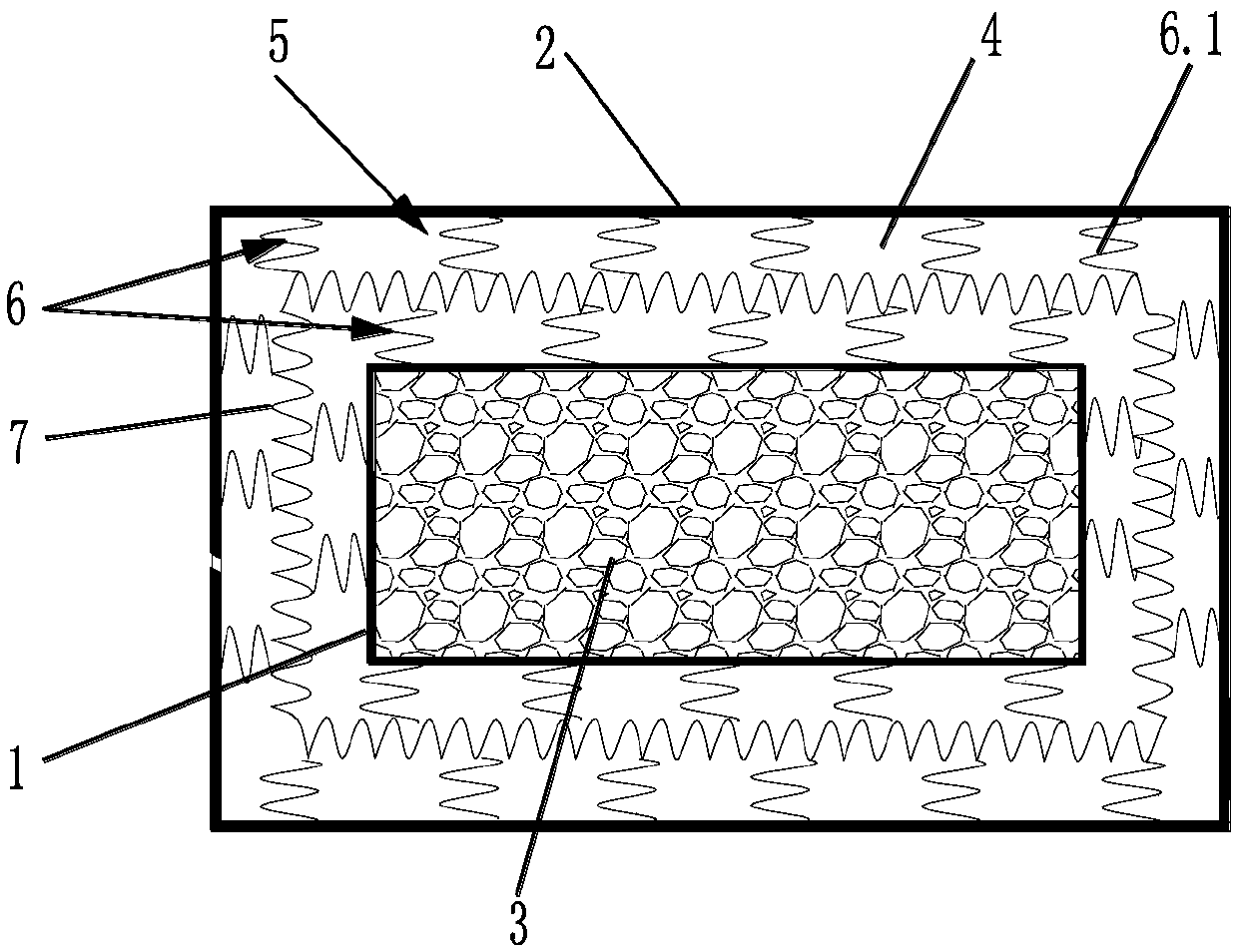

[0037] Such as image 3 The third embodiment of the present invention shows a multi-hazard combined protective function steel pipe concrete structure based on the principle of deformation and energy absorption. The implementation and production steps of this embodiment 3 are the same as those of embodiment 1, except that the steel pipe 1 and the protective cover 2 are horizontal The cross-sectional shape is set to a rectangular shape, and the corrugated plate assembly 6 of each circle is arranged in a rectangular shape by several corrugated steel plates 6.1 to meet the needs of other square columns, rectangular columns, beams, and plate structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com