Direct current converter valve with linear valve layer arrangement

A DC converter valve, a straight-line technology, applied in the direction of converting AC power input to DC power output, electromechanical devices, output power conversion devices, etc., can solve the problems of large valve hall area and long valve floor, etc. Achieve the effect of saving floor space, reducing width, and reducing projected area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

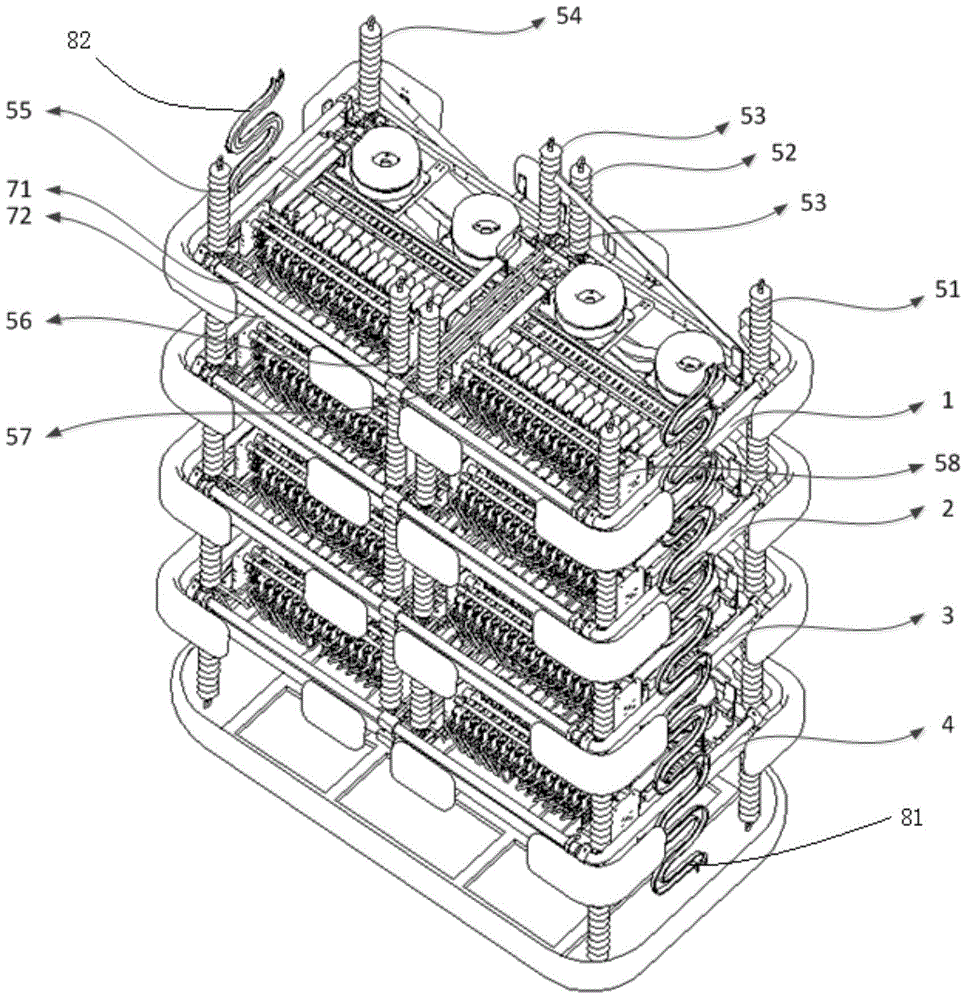

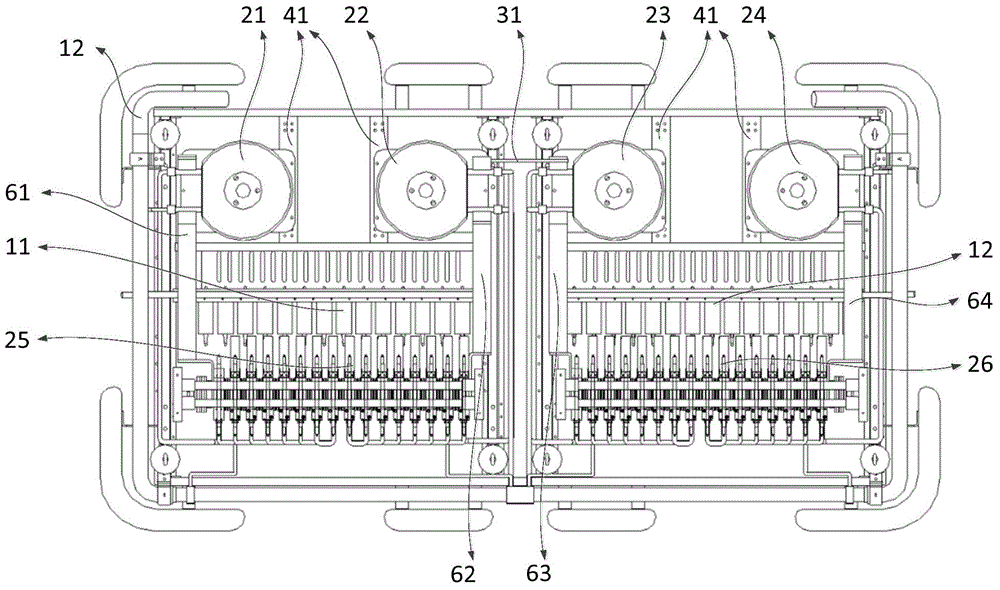

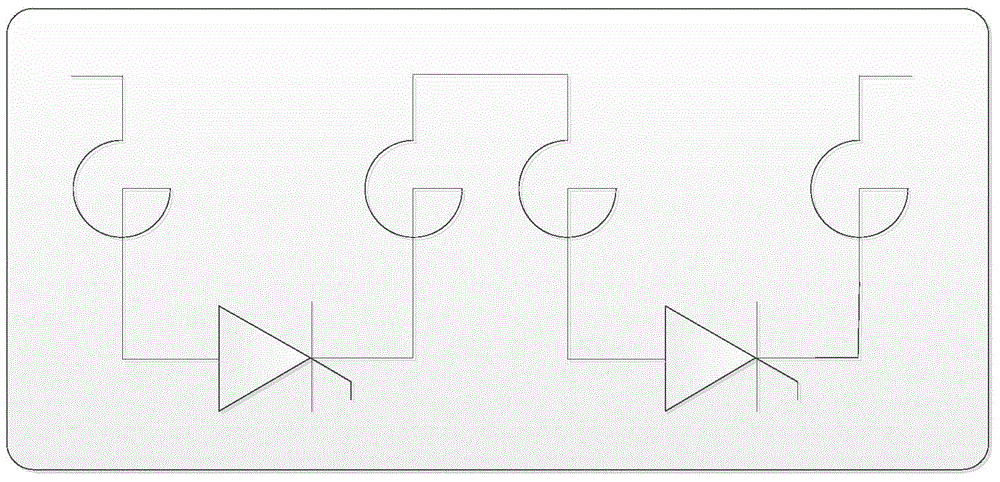

[0020] see figure 1 , figure 2 and image 3 , the direct current converter valve with in-line valve layer arrangement includes a top shield, at least two valve layers and a bottom shield connected sequentially from top to bottom; the at least two valve layers are stacked up and down; the last The upper valve layer and the top shield are suspended and connected through the interlayer insulator 5; the lowest valve layer and the bottom shield are also suspended and connected through the interlayer insulator 5; it also includes the direct current arranged around the inline valve layer The cooling water pipe on the outside of the diverter valve; the cooling water pipe is an annular water pipe, and the water connection between different valve layers is realized through the annular water pipe; each valve layer includes two first valve modules 11 and second valve modules 12 arranged in series; The first valve module 11 includes a first reactor 21 , a first thyristor assembly 25 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com