Optical module for modularly designed industrial plug-in connectors

A plug-in connector, fiber optic connector technology, applied in the direction of optics, optical components, instruments, etc., can solve the problem that the end sides cannot be tilted relative to each other

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

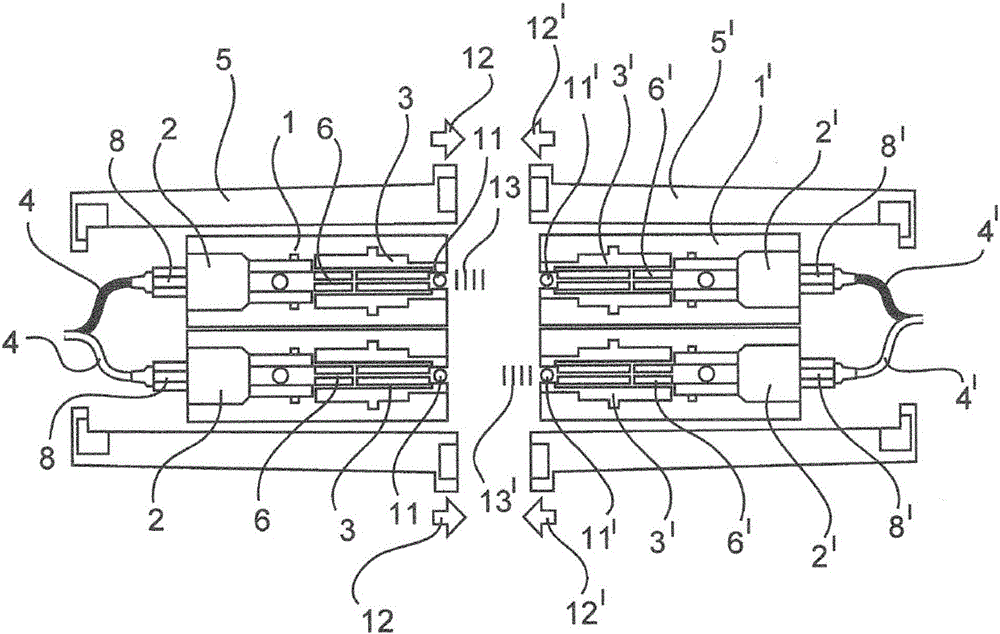

[0034] exist figure 1 In , superscripted notations are also used in addition to unsuperscripted ones. Unsuperscripted references refer to the plug-in connector, while superscripted references refer to the mating plug-in connector. However, a superscripted number indicates the same feature or the same component as a non-superscripted number and is therefore not specifically recited in the claims.

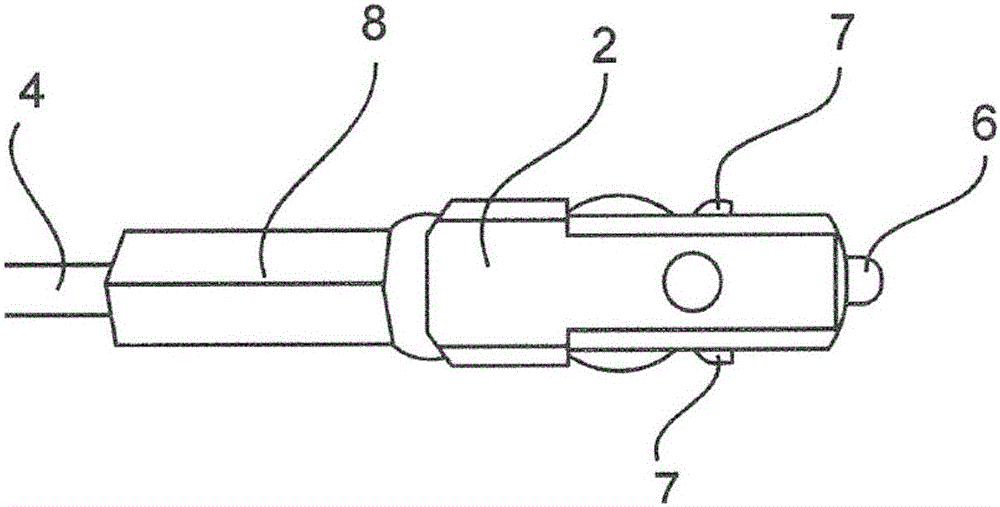

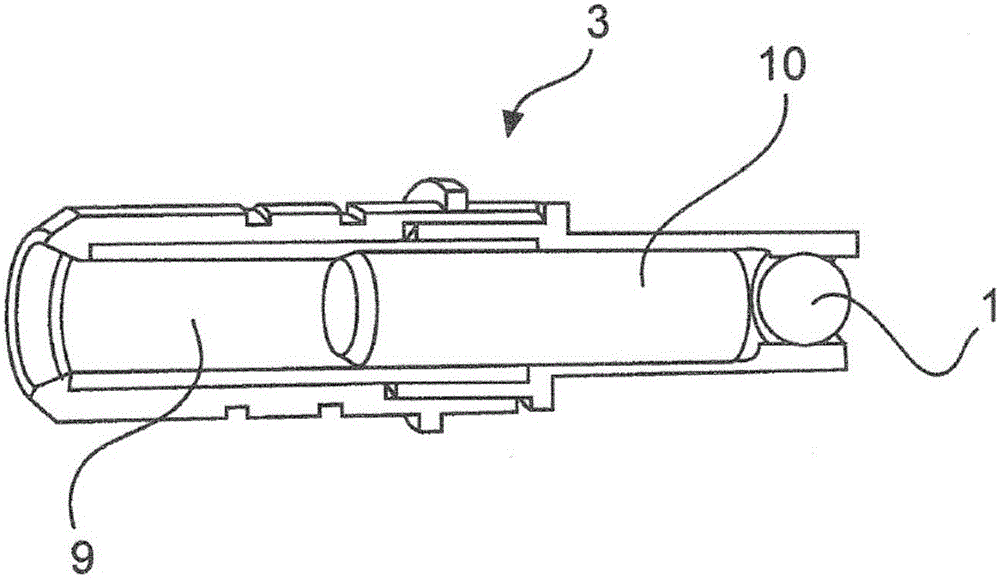

[0035] The modules 1, 1' of the invention have substantially the same parallelepiped shape. On the connection side, a fiber optic connector 2, here called an SC connector, is locked into the module 1, 1'. SC plugs are used as the standard for LAN connections and are therefore widely used.

[0036] On the plug-in side, part of the ferrule 6 protrudes from the SC plug 2 in which glass fibers for signal transmission are embedded. On the connection side, a glass fiber cable 4 is connected to the SC plug 2 . In order to reversibly lock the module 1, 1', locking hooks are molded onto ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com