A Hydrophobic Agent for Reducing the Risk of Postharvest Cherry Cracking

A water-repellent, cherry technology, applied in the direction of protecting fruits/vegetables with a coating protective layer, can solve the problems that have not yet been achieved, and achieve the effects of easy operation, reduced fruit cracking, and reduced water absorption speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] At normal temperature and pressure, weigh 600g of sucrose ester and pour it into 1L of 40°C water, stir, measure 1200ml of corn oil and pour it into the mixed solution, stir with a stirrer for 2 to 3 minutes until the sucrose ester is completely dissolved, and the speed of the stirrer is 300 rev / min, the corn oil is evenly dispersed in the solution, and the milky white mother liquor is prepared. Add the prepared mother liquor into 149L of clean water at room temperature, and stir with a mixer for 2 to 3 minutes to obtain a uniform and stable hydrophobic agent. The mixer speed is 3000 rpm. The post-harvest cherry fruit is dipped in the prepared hydrophobic agent or sprayed with the hydrophobic agent, soaked or sprayed for 1 minute, and then pre-cooled and graded.

Embodiment 2

[0020] At normal temperature and pressure, weigh 900g of sucrose ester and pour it into 1L of 50°C water, stir, measure 1800ml of corn oil and pour it into the mixed solution, and stir with a stirrer for 2 to 3 minutes until the sucrose ester is completely dissolved. The speed of the stirrer is 850 revolutions per minute, corn oil is uniformly dispersed in the solution, and the milky white mother liquor is prepared. Add the prepared mother liquor into 199L of clean water at room temperature, stir with a mixer for 2 to 3 minutes to obtain a uniform and stable hydrophobic agent, and the mixer speed is 5000 rpm. The post-harvest cherry fruit is dipped in the prepared hydrophobic agent or sprayed with the hydrophobic agent, soaked or sprayed for 1 minute, and then pre-cooled and graded.

Embodiment 3

[0022] Under normal temperature and pressure, weigh 750g of sucrose ester and pour it into 1L of 60°C clear water, stir, measure 1500ml of corn oil and pour it into the mixed solution, stir with a stirrer for 2-3 minutes until the sucrose ester is completely dissolved, the speed of the stirrer is 600 rev / min, the corn oil is evenly dispersed in the solution, and the milky white mother liquor is prepared. Add the prepared mother liquor into 179L of clean water at room temperature, stir with a mixer for 2 to 3 minutes to obtain a uniform and stable hydrophobic agent, and the mixer speed is 4000 rpm. The post-harvest cherry fruit is dipped in the prepared hydrophobic agent or sprayed with the hydrophobic agent, soaked or sprayed for 1 minute, and then pre-cooled and graded.

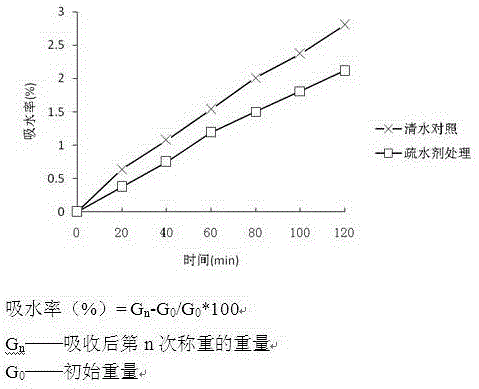

[0023] Taking the "red light" variety as an example, the application effect of the present invention in the test is as follows: figure 1 :

[0024] figure 1 Comparison of fruit water absorption rate of "R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com